Bidirectional self-balance shear loading device for fired shale masonry and test method therefor

A loading device and self-balancing technology, applied in measuring devices, using stable shear force to test material strength, and using stable tension/pressure to test material strength, etc., can solve the problem of reduced test convenience and stable reaction frame. It can solve the problems of reduced stability and insufficient lateral rigidity of the bracket of the reaction frame, and achieve the effect of high stability of bidirectional self-balancing loading, improved accuracy and convenience, and quick assembly and disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

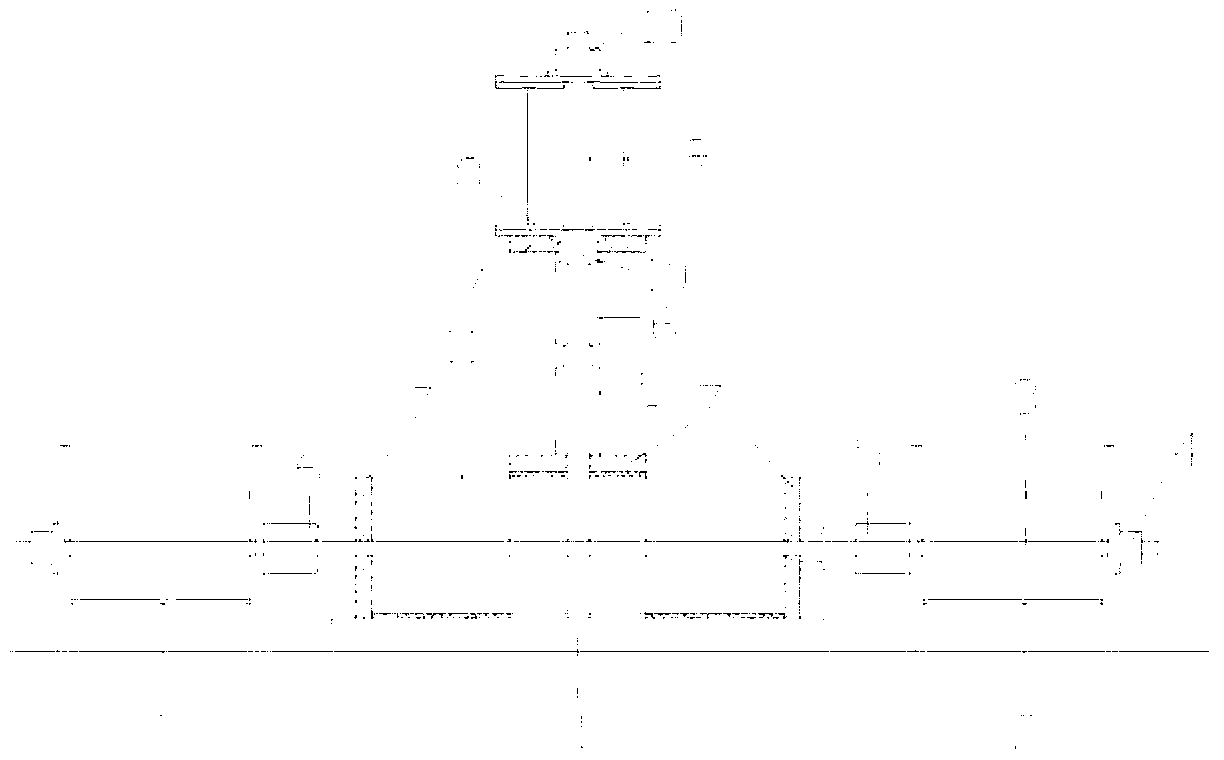

[0029] Such as Figure 1 ~ Figure 3 As shown, the sintered shale masonry two-way self-balancing shear pressure loading device of the present invention includes a rectangular base 1, two vertical bolt rods 9 are symmetrically installed at both ends of the width direction of the base 1, and two vertical bolt rods 9 The upper end is equipped with a vertical loading steel beam 8; Figure 4 , Figure 5 As shown, the vertically loaded steel beam 8 is composed of two parallel first horizontal plates 81 and two first vertical plates 82 connected in parallel between them, the two ends of the first horizontal plate 81 are symmetrically arranged Mounting holes 83, the upper end of each vertical bolt rod 9 passes through and is fixedly connected through the mounting holes 83 of the two first horizontal plates 81 of the vertically loaded steel beam 8, and the top end of the vertical bolt rod 9 is connected by a vertical nut. And the gasket 10 is fixed on the first horizontal plate 81 loc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com