Application method of straight gear tooth rack cutter CAD (computer-aided design) drafting system

A system application, comb-tooth knife technology, applied in the field of gear straight-toothed combs, can solve the problems of cumbersome calculation and error-prone comb-tooth tools, and achieve the effect of shortening the design cycle, reducing the strength of design and calculation, and reducing design costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In conjunction with the accompanying drawings, the present invention is further described in detail through the embodiments.

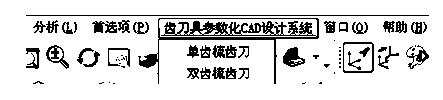

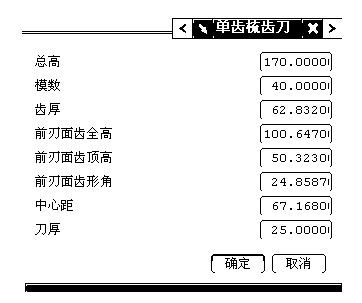

[0032] The application method of the CAD drawing system for straight-toothed and comb-toothed cutters described in this embodiment is to construct a CAD system for straight-toothed and comb-toothed gears based on the UG platform for the development technology roadmap, analyze and summarize the three-dimensional parametric technology, and use parameters It realizes the automatic generation of the 3D model and 2D CAD graphics of the straight-toothed comb tool by using the advanced technology and UG secondary development technology.

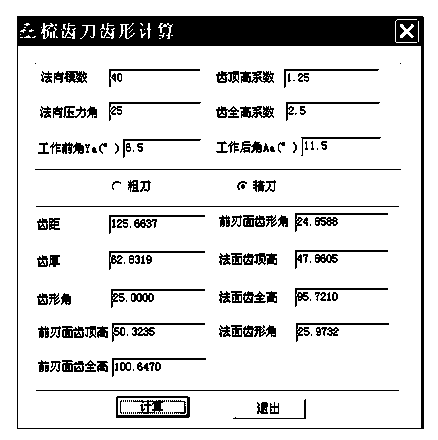

[0033] This embodiment is to create a new MFC project framework in VC and name the project, and design a dialog box in the project resource. After running, the effect is as follows figure 1 shown. In this design, various parameters are initialized in the void CCaucDlg::OnButton1(){} function. Then add C++ codes in v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com