Skewed rotor core and manufacturing method thereof and motor comprising skewed rotor core

A technology of a skewed rotor and a manufacturing method, which is applied in the manufacture of stator/rotor body, magnetic circuit rotating parts, magnetic circuit shape/pattern/structure, etc., can solve the problem of reducing motor vibration and noise, high processing cost, and difficult to eliminate high Sub-harmonics and other problems, to achieve the effect of reducing processing cycle and cost, eliminating high-order harmonics, reducing vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing:

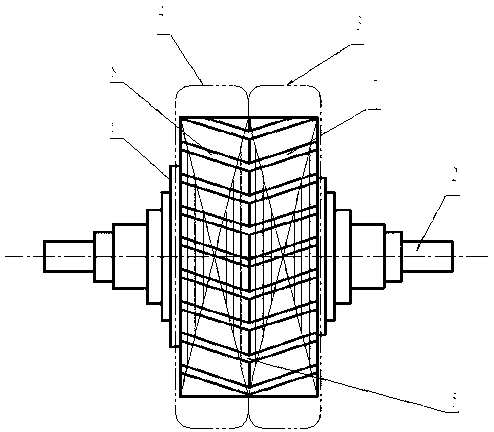

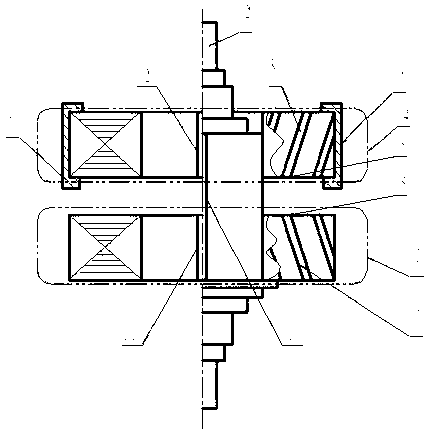

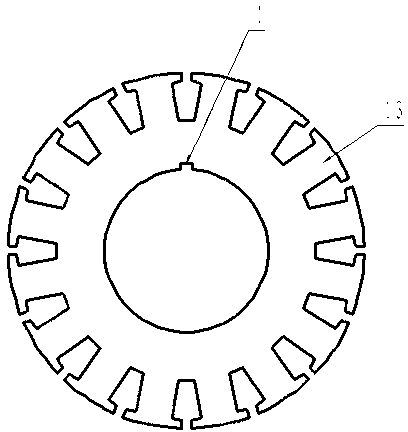

[0030] refer to Figure 1 to Figure 3 , a skewed rotor core, which includes a rotating shaft 2, a skewed rotor core I3 and a skewed rotor core II4, the skewed rotor core I3 and the skewed rotor core II4 are laminated by rotor punching sheets The oblique direction of the oblique rotor core I 3 core slot I 7 and the oblique rotor core II 4 iron core slot II 8 are symmetrically arranged, and the oblique rotor core I 3 and oblique rotor iron The inclined grooves of the core slots of core II 4 form inflection points 5 at the junction. In order to stack and guide, the inner hole of each rotor punch I13 of the skewed rotor core I3 is provided with a guide keyway I1, and the inner hole of each rotor punch II of the skewed rotor core II4 is also provided with a guide keyway II; After the rotor core I3 is stacked, the connection keyway I11 is integrally processed, and the skewed ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com