Self-tuning type frequency conversion power generation device and method

A power generation device and self-tuning technology, applied in the direction of generators/motors, electrical components, piezoelectric effect/electrostrictive or magnetostrictive motors, etc., can solve the problem of reduced power generation capacity, piezoelectric vibrator natural frequency non-resonance, Problems such as small frequency change range, to achieve the effect of power generation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

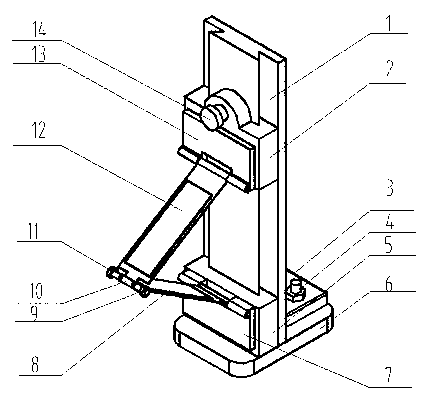

[0020] Attached below figure 1 , the present invention will be described in further detail. It should be emphasized that the following description is exemplary only and not intended to limit the scope and application of the present invention.

[0021] The self-tuning frequency conversion micro-generation device consists of guide rails (1), movable sliders (2), fixed sliders (5), hinges (7, 10, 13), piezoelectric vibrators (8, 12), mass blocks ( 9, 11), base (6), angle steel (3), screws (14), and bolts (4). The angle steel (3) is located at the back of the guide rail, and is connected with the base (6) and the guide rail (1) through bolts (4) to support and fix it. The movable slider (2) can slide freely on the guide rail (1), and can be fixed on the guide rail (1) by screws (14) during adjustment. The fixed slider (5) is fixed together with the guide rail (1) by adhesive. Two threaded holes are designed on the front of the base (6), and the angle steel (3) is fixed with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com