Secondary water injection for diffusion combustion systems

A combustion system and auxiliary water pipe technology, applied in the direction of combustion chamber, turbine/propellant fuel delivery system, combustion equipment, etc., can solve the problems of large emission and unacceptable dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

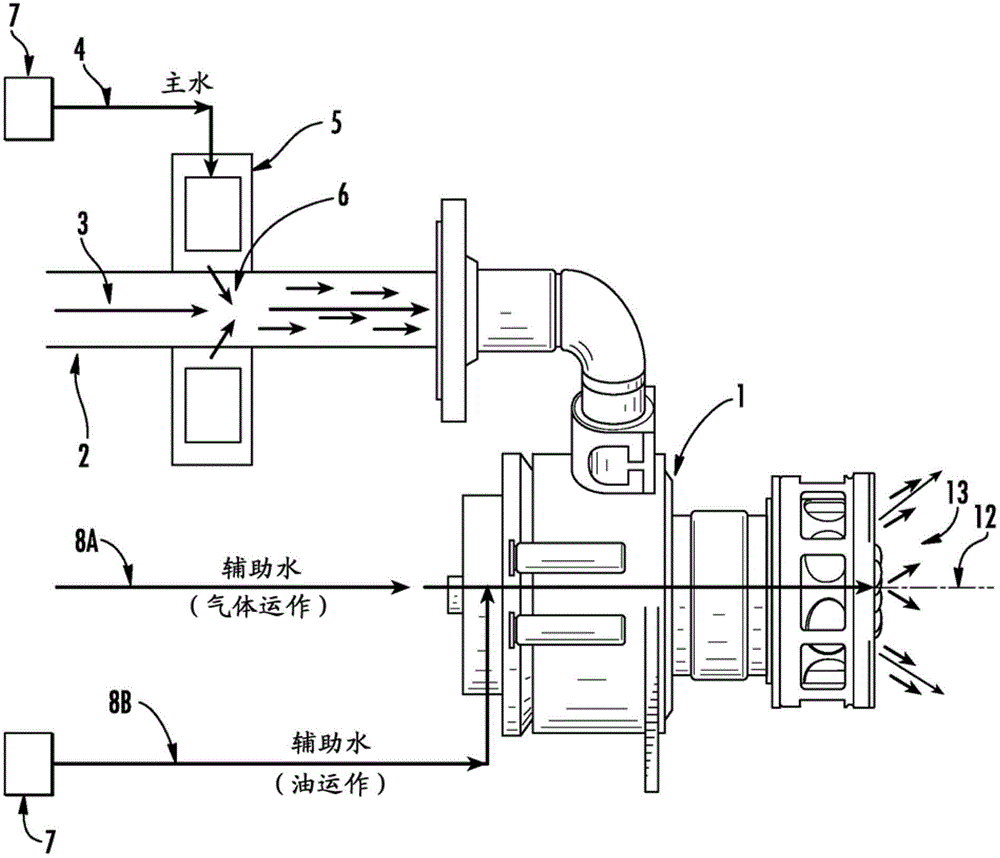

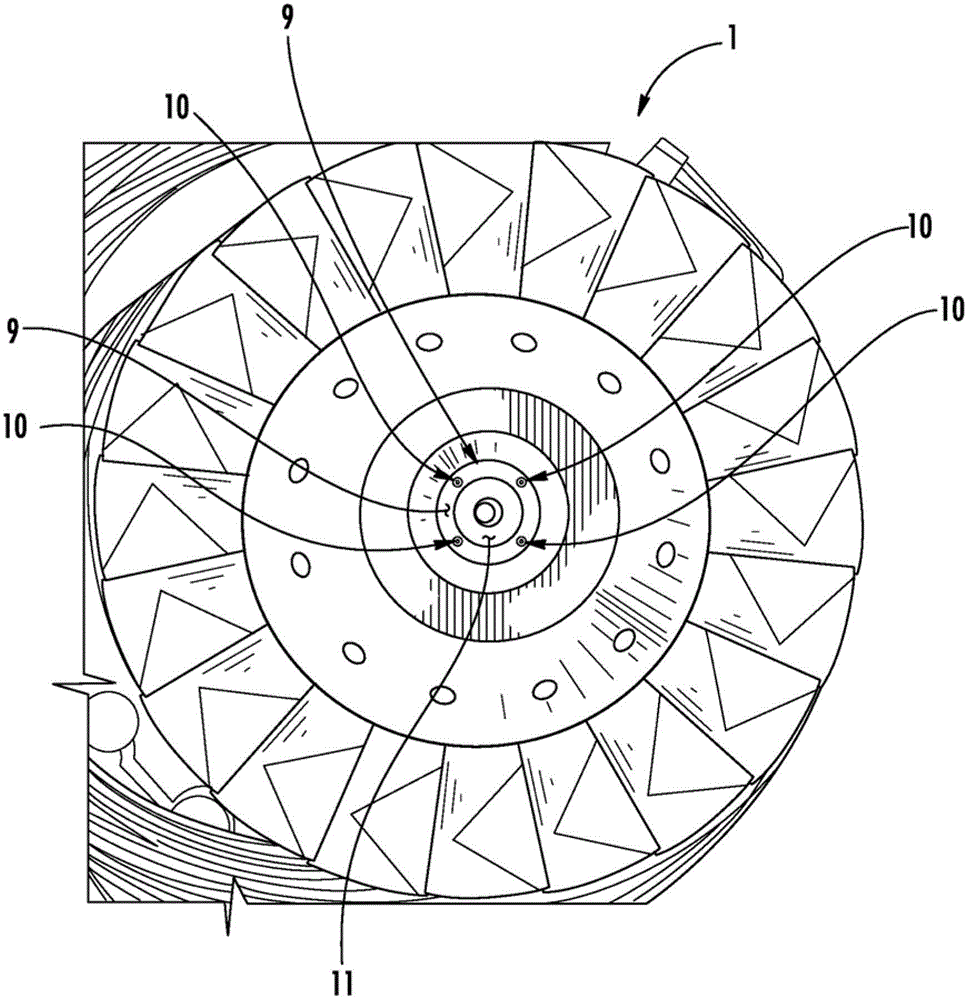

[0014] refer to figure 1 , a fuel nozzle assembly 1 for a turbine engine diffusion flame combustor is provided. Fuel line 2 may supply fuel 3 to fuel nozzle assembly 1 . A primary fluid (water) line 4 may supply a first fluid, such as water, to a water injection annular donut 5 coupled to the fuel line 2 . The water injection annular baffle 5 may be mounted to surround or enclose the fuel line 2 . The water injection annular baffle 5 may facilitate the injection of one or more water streams 6 into the fuel 3 flowing through the fuel line 2 .

[0015] Additionally or alternatively, water is injected into the combustion flame zone of the combustor located downstream of the fuel nozzle assembly 1 . Injecting water into both the fuel and the combustion zone can control exhaust emissions, especially NO X .

[0016] As used herein, water refers to its various phases, including liquid or water vapor, and combinations of liquid and water vapor, and includes liquid droplets. Here...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap