Asbestos tile forming method

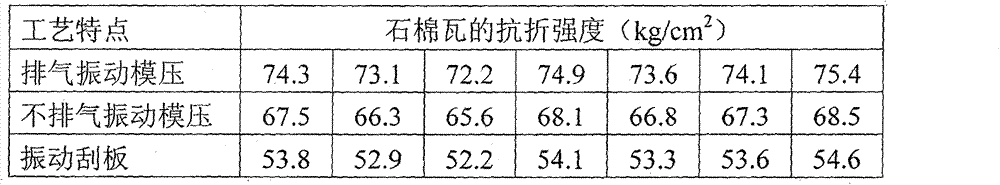

A molding method and asbestos tile technology, applied in the field of asbestos tile molding, can solve problems such as damage, dimples, and many bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present embodiment will be described in detail below in conjunction with the accompanying drawings.

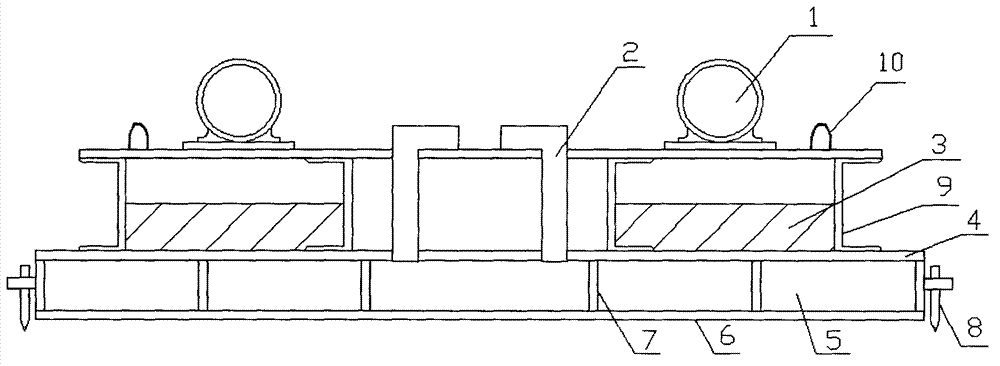

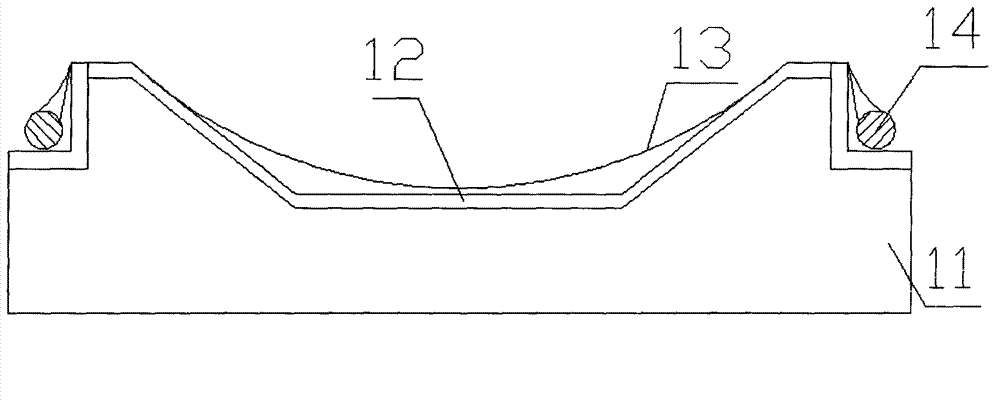

[0033] The invention adopts a hollow die structure capable of natural exhaust, which can discharge part of the water and air in the mortar during the vibration compaction process. Die structure includes attached vibrator 1, exhaust pipe 2, additional load block 3, upper cover plate 4, exhaust chamber 5, lower cover plate 6, rib plate 7, guide cone 8, vibration transmission frame 9, lifting hole 10. Attached vibrator 1 is provided with a vibration transmission frame 9, the vibration transmission frame 9 is welded by a steel plate and a channel steel, an additional load block 3 is arranged at the bottom of the vibration transmission frame 9, and the upper cover plate 4 is located below the vibration transmission frame 9, and the upper cover plate 4, the lower cover plate 6 and the rib plate 7 form an exhaust chamber 5, and the rib plate 7 adopts a steel plate with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com