Method for flexibly assembling leading edge flap

A flexible assembly, leading edge flap technology, applied in aircraft assembly, ground installation, transportation and packaging, etc., can solve problems such as the inability to achieve flexible positioning of leading edge flap products, the large number of cardboards in the shape of the frame, and the poor openness. , to achieve good flexibility and compatibility, advanced structure, and reduce the effect of assembly tooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] This embodiment is a method for flexible assembly of leading edge flaps.

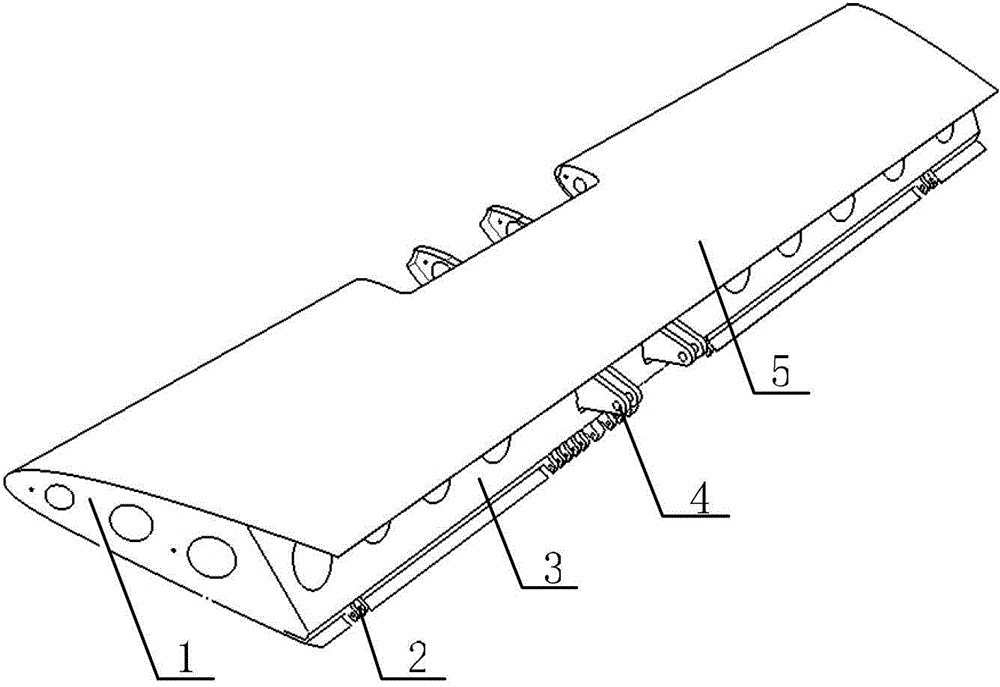

[0035] refer to figure 1 , figure 2 , the leading edge flap components are composed of the following typical structures, 1#-13# rib 1, 1#-3# intersection joint 2, angled beam 3, 1#-2# control joint 4, skin 5, Wherein, two coordinate positioning holes are respectively opened on each wing rib.

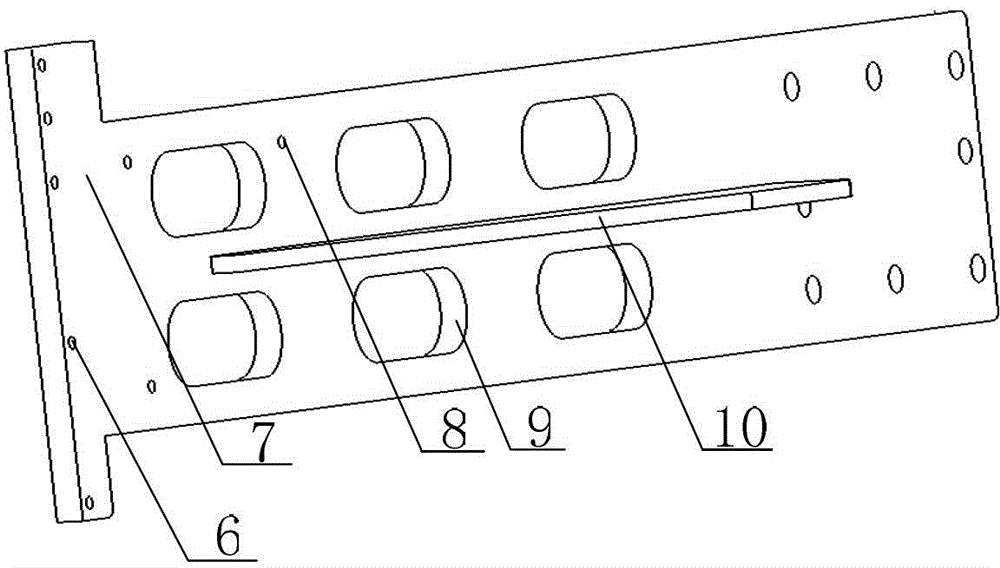

[0036] The positioning part of the leading edge flap rib baffle is a "convex"-shaped flat plate structure. The front part of the positioning plate is provided with a rib positioning surface 7, and the two sides of the middle part are provided with reinforcing ribs 10. There are 3 ribs above and below the reinforcing ribs 10. The oval lightening grooves 9 are distributed symmetrically. The rib positioning surface 7 is provided with five coordinate positioning holes 6 distributed in a straight line perpendicular to the central axis of the positioning member, corresponding to the two positioning holes on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com