Plastic sleeve and steel pipe combined cast-in-place concrete hollow pipe pile and construction method thereof

A technology of plastic casing and construction method, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of large impact on durability, poor ability to resist lateral deformation, poor ability to resist lateral deformation, etc., and achieve increased strength And the ability to resist lateral deformation, improve the strength and resistance to lateral deformation, and improve the effect of mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Technical requirements for welding construction between immersed tubes, connecting pipes, and ribs, design and construction requirements for corrosion-resistant concrete, technical requirements for pile concrete construction, etc., will not be repeated in this implementation mode, and focus on the implementation mode of the structure involved in the present invention .

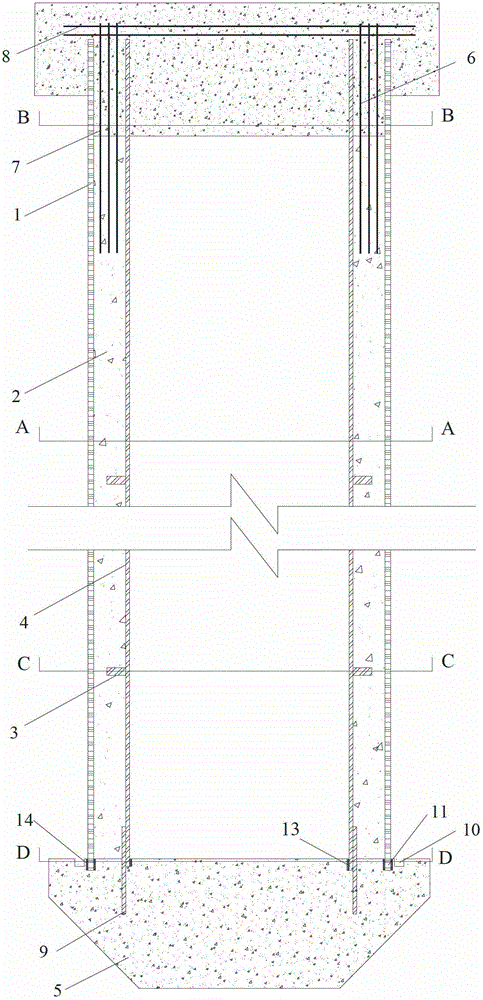

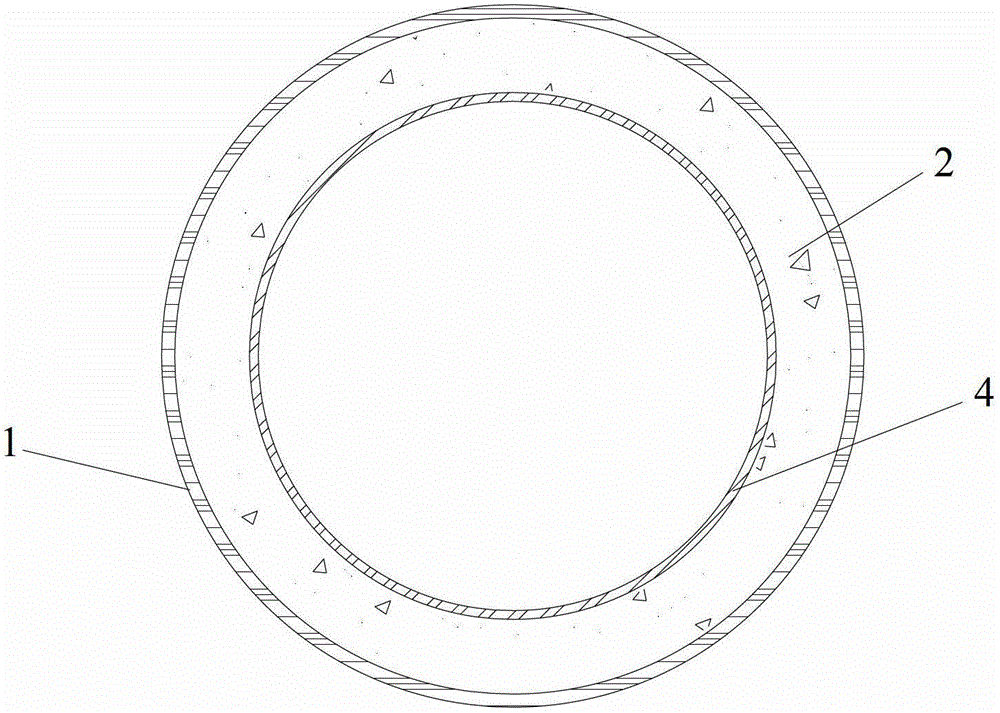

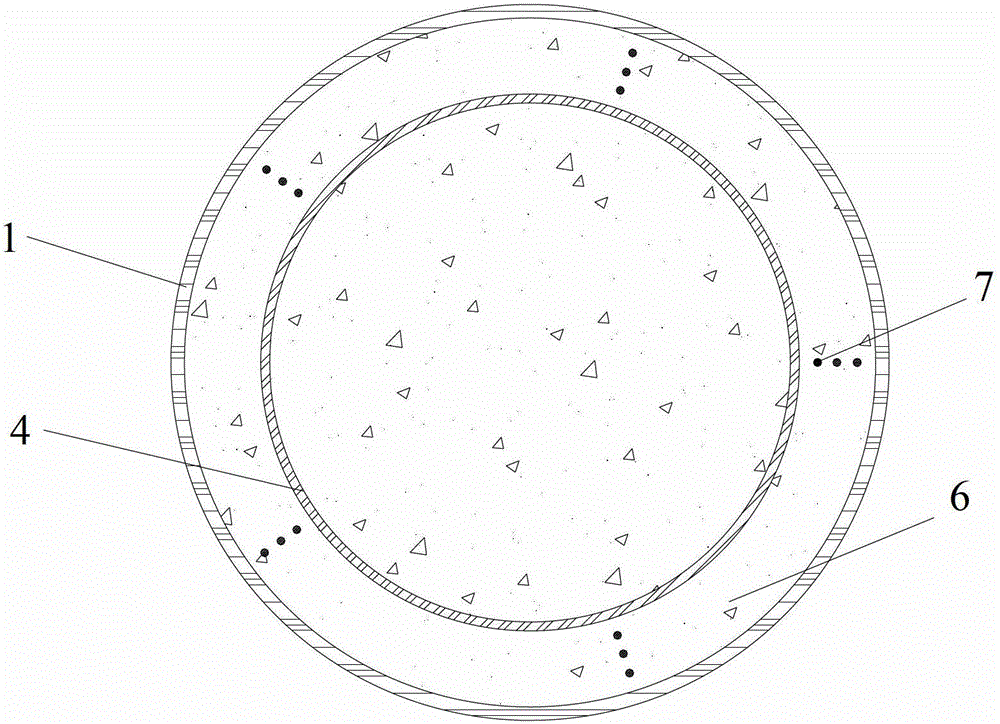

[0041]figure 1 It is a cross-sectional view of the cast-in-place concrete hollow pipe pile structure composed of plastic casing and steel pipe. figure 2 yes figure 1 Sectional view of the pile body along the A-A line without cutting to the stiffened rib plate, image 3 yes figure 1 Sectional view of the built-in closed end of the top of the pile along the line B-B, Figure 4 yes figure 1 The sectional view of the pile body along the C-C line to the stiffened rib plate, Figure 5 yes figure 1 Sectional view of the top of the pile tip along line D-D. Such as Figure 1-Figure 5 The cast-in-situ co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com