Double-layer plastic sleeve bulk material and concrete stiffness core composite pile and construction method thereof

A technology of strong core combined pile and plastic casing, which is applied in sheet pile wall, soil protection, infrastructure engineering and other directions, can solve the problem that the bearing capacity of soil between piles cannot be fully utilized, the overall strength of the foundation is limited, and the later settlement Deformation is not easy to control and other problems, to achieve effective control of settlement deformation, improve corrosion resistance, and save engineering costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Reinforcement welding construction technical requirements, pile concrete design and construction requirements, double-layer hollow plastic casing and casing joint bonding construction requirements, etc., will not be repeated in this embodiment, and focus on the embodiment of the structure involved in the present invention .

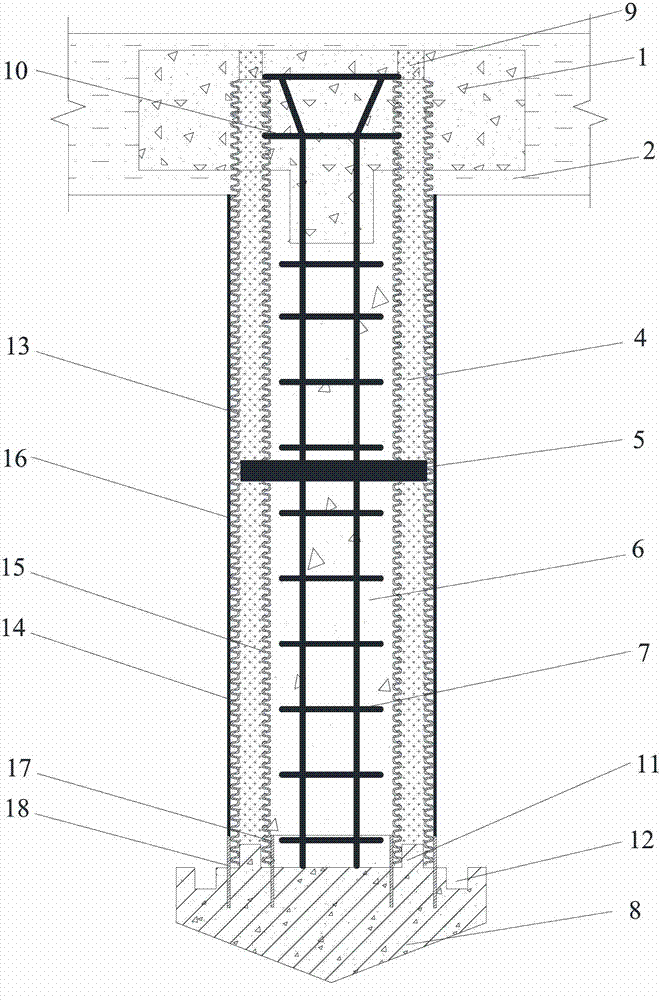

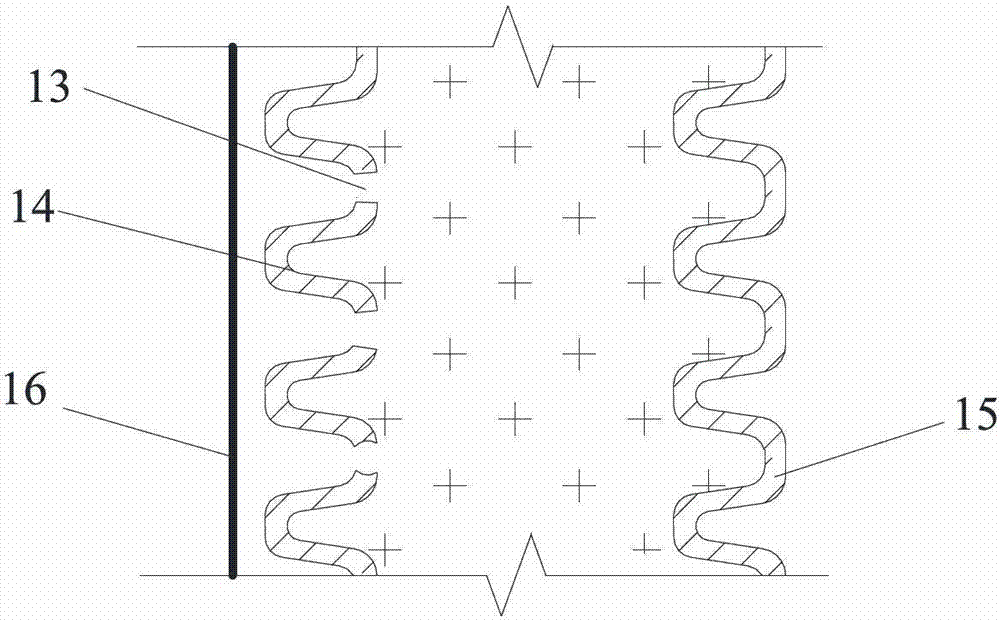

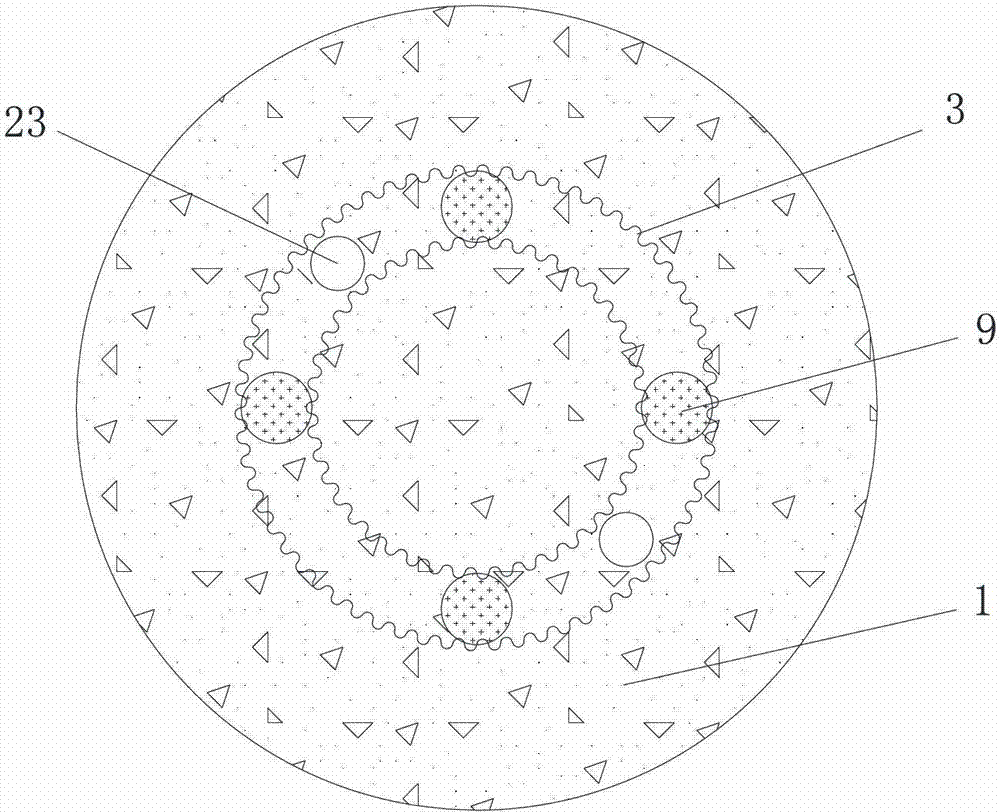

[0047] figure 1 It is a structural schematic diagram of the double-layer plastic casing bulk material and concrete core combined pile of the present invention, referring to figure 1 The double-layer plastic sleeve loose material and concrete core composite pile shown includes a concrete cover plate with holes on the top of the pile 1, double-layer hollow plastic sleeve 3, loose material 4, reinforced concrete pile core 6, and prefabricated pile tip 8. Double-layer hollow plastic casing joint 5. The outer tube 14 and the inner tube 15 together form a double-layer hollow plastic sleeve 3, the top of the double-layer hollow plastic sleeve 3 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com