Wood bark paint-free multilayer solid composite ground floor

A solid wood composite floor and solid wood composite technology, applied in the field of veneer paint-free multi-layer solid wood composite floor, can solve the problems of high cost, long production process, no function of environmental humidity control, etc., and achieve the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

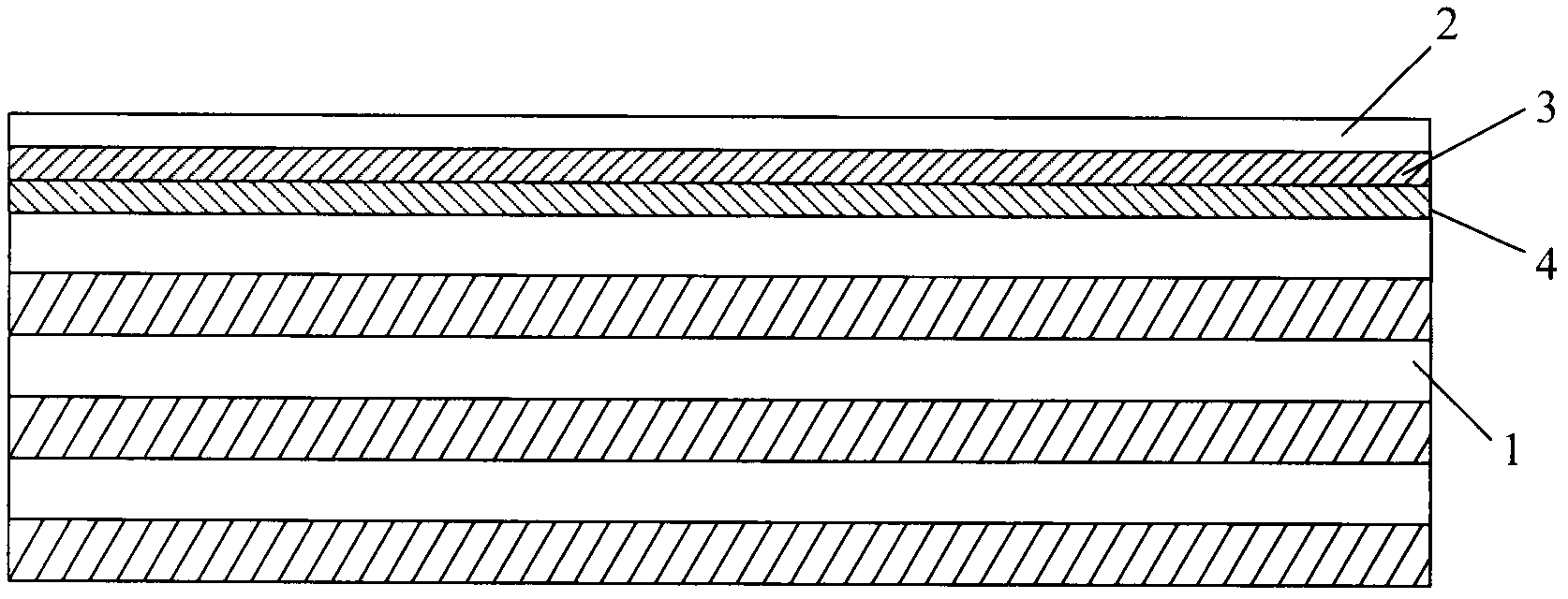

[0011] Such as figure 1 As shown, the veneer paint-free multi-layer solid wood composite flooring of the present invention comprises a substrate 1, impregnated paper 2, veneer 3, and balancing paper 4, and the impregnated paper 2, veneer 3, and balancing paper 4 are sequentially laid on the substrate 1 from top to bottom, and the substrate 1 and impregnated paper 2, veneer 3, and balance paper 4 are hot-pressed into one body, and the finished product can be made by making tenons and grooves according to the specific conditions. The veneer paint-free multi-layer solid wood composite floor of the invention has natural and beautiful solid wood natural texture, and the processing procedure is simple and easy. After forming, the veneer does not need cloth glue, and can be formed by direct hot pressing, and has hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com