Cage type optical fuze testing device

A testing device and fuze technology, which is applied in fuzes, weapon accessories, offensive equipment, etc., can solve the problems of large restrictions on the shape of the full bomb measurement, and there is no test device for testing optical fuzes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

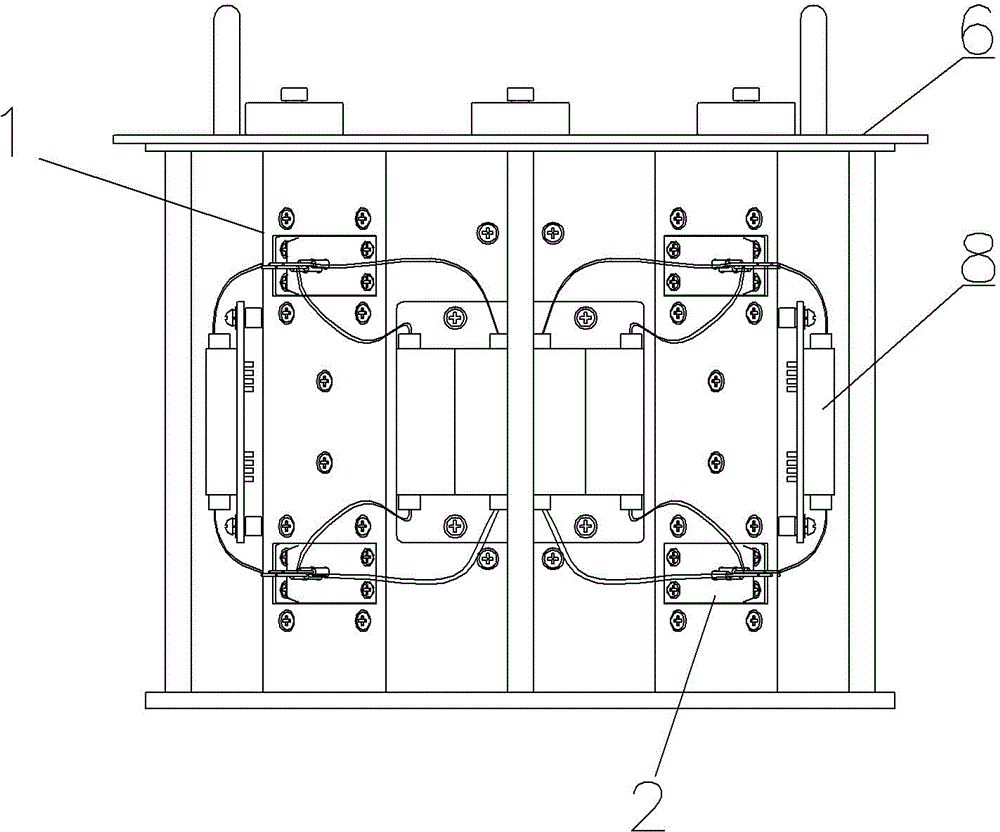

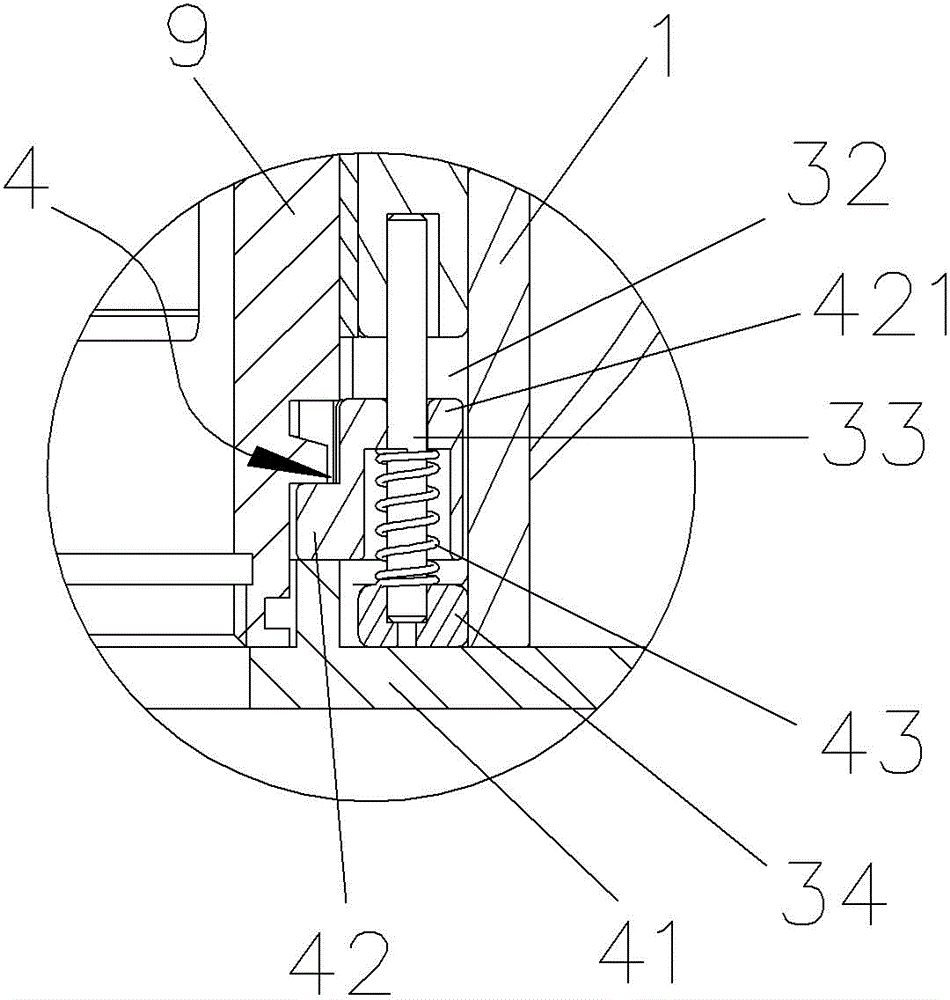

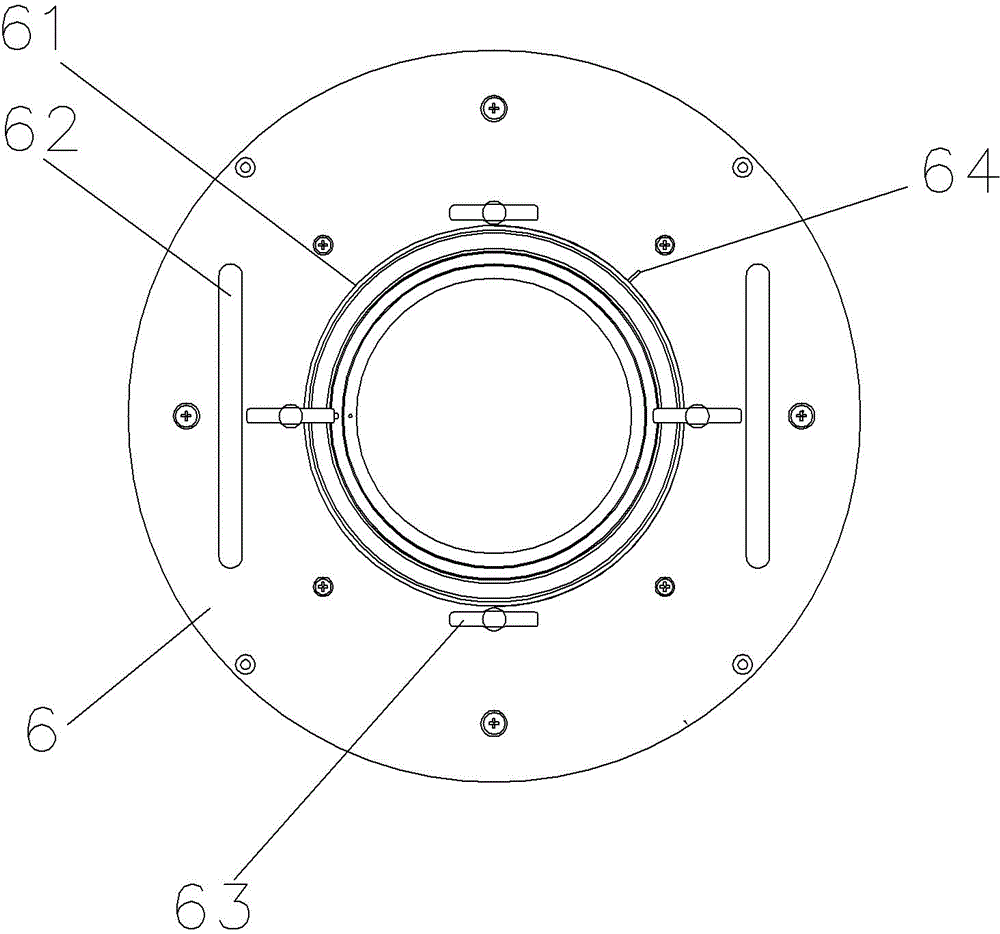

[0017] Such as Figure 1 to Figure 4 A kind of embodiment of the present invention shown, comprises cylindrical frame 1, defines the axial direction of frame 1 as the up and down direction, and the radial direction of frame 1 is horizontal direction, is provided with in the frame 1 and is provided with for being tested along the axial direction. The fuze cabin 9 is inserted into the installation channel from top to bottom, and the installation channel of the frame 1 is provided with an optical channel corresponding to the fuze cabin window 91 of the fuze cabin 9 in a one-to-one correspondence with the fuze cabin window 91 of the fuse cabin 9 and is provided with a transceiver in the optical channel. The optical collimator 2 for the optical signal, the terminal of the optical collimator 2 is exposed outside the corresponding window opened outside the frame 1 and is connected with the optical switch 8 installed on the outer surface of the frame 1 through an optical cable. The in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com