Photosensitive drum, transmission component for photosensitive drum and assembly method of photosensitive drum

A technology of transmission parts and photosensitive drums, which is applied in the direction of transmission, gear transmission, optics, etc., can solve the problems of easy to be polluted by glue, loose photosensitive drum photosensitive surface, etc., and achieve the effect of simplifying complexity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The photosensitive drum and its transmission parts and the assembly method of the photosensitive drum of the present invention will be described in detail below with reference to the accompanying drawings.

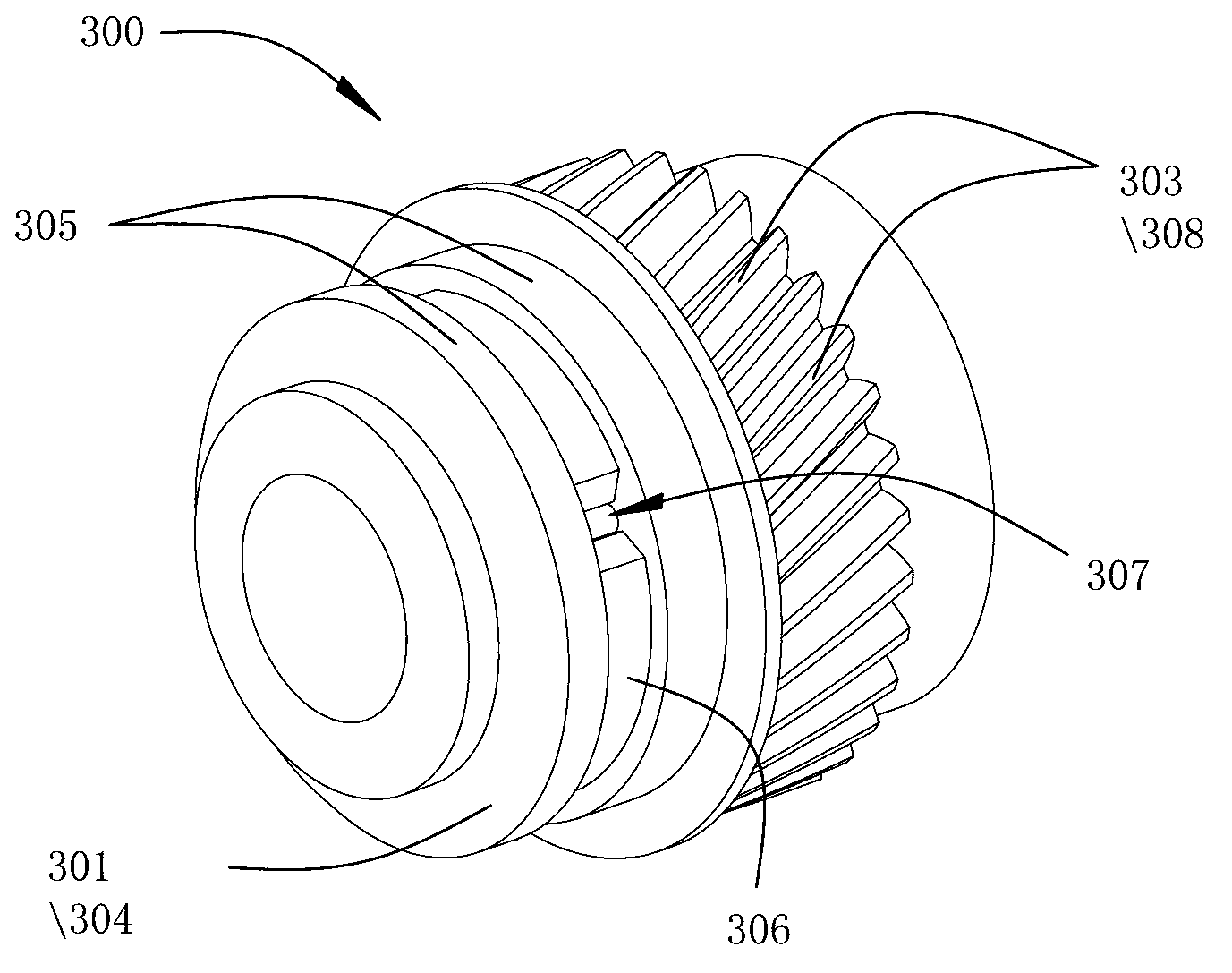

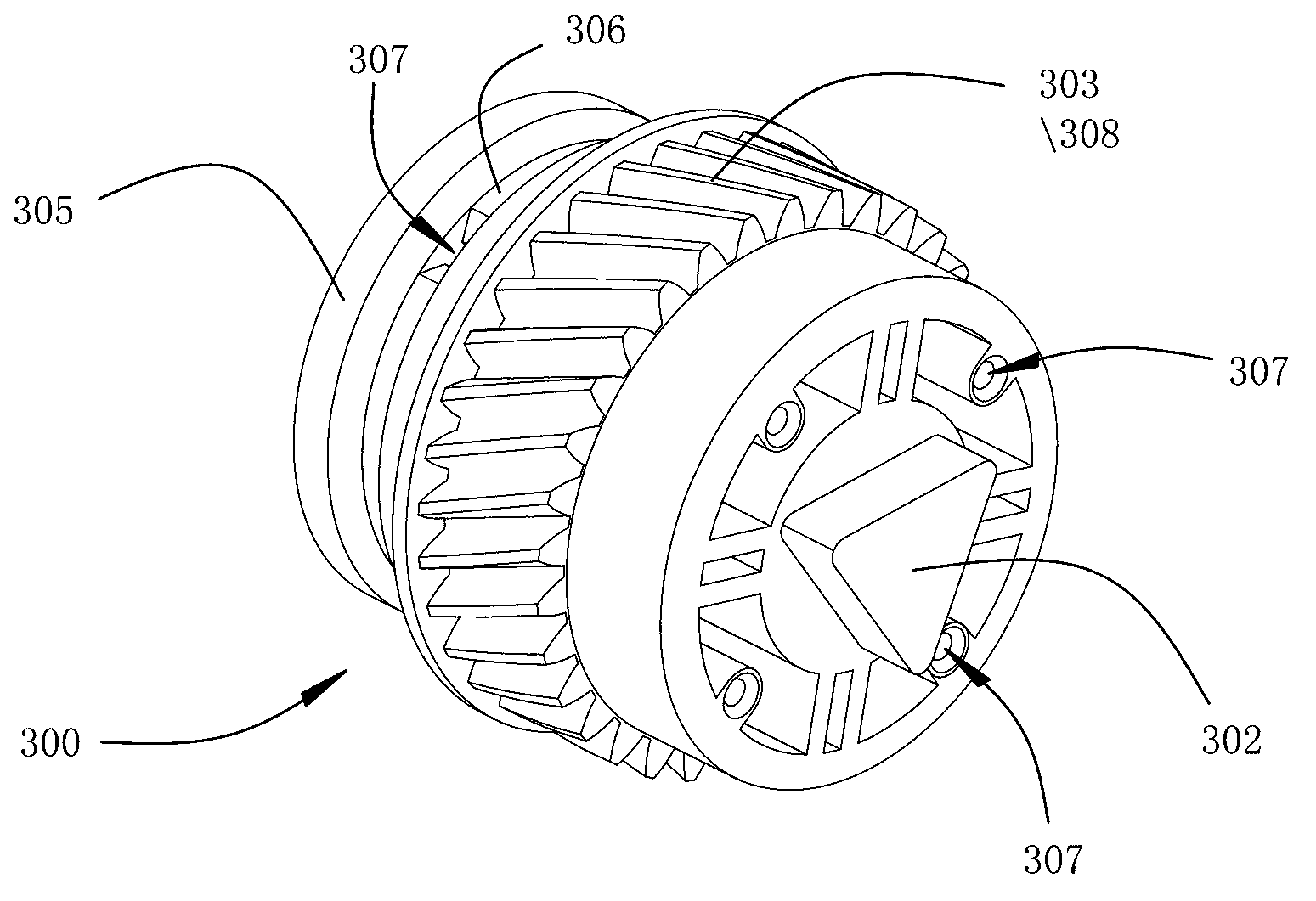

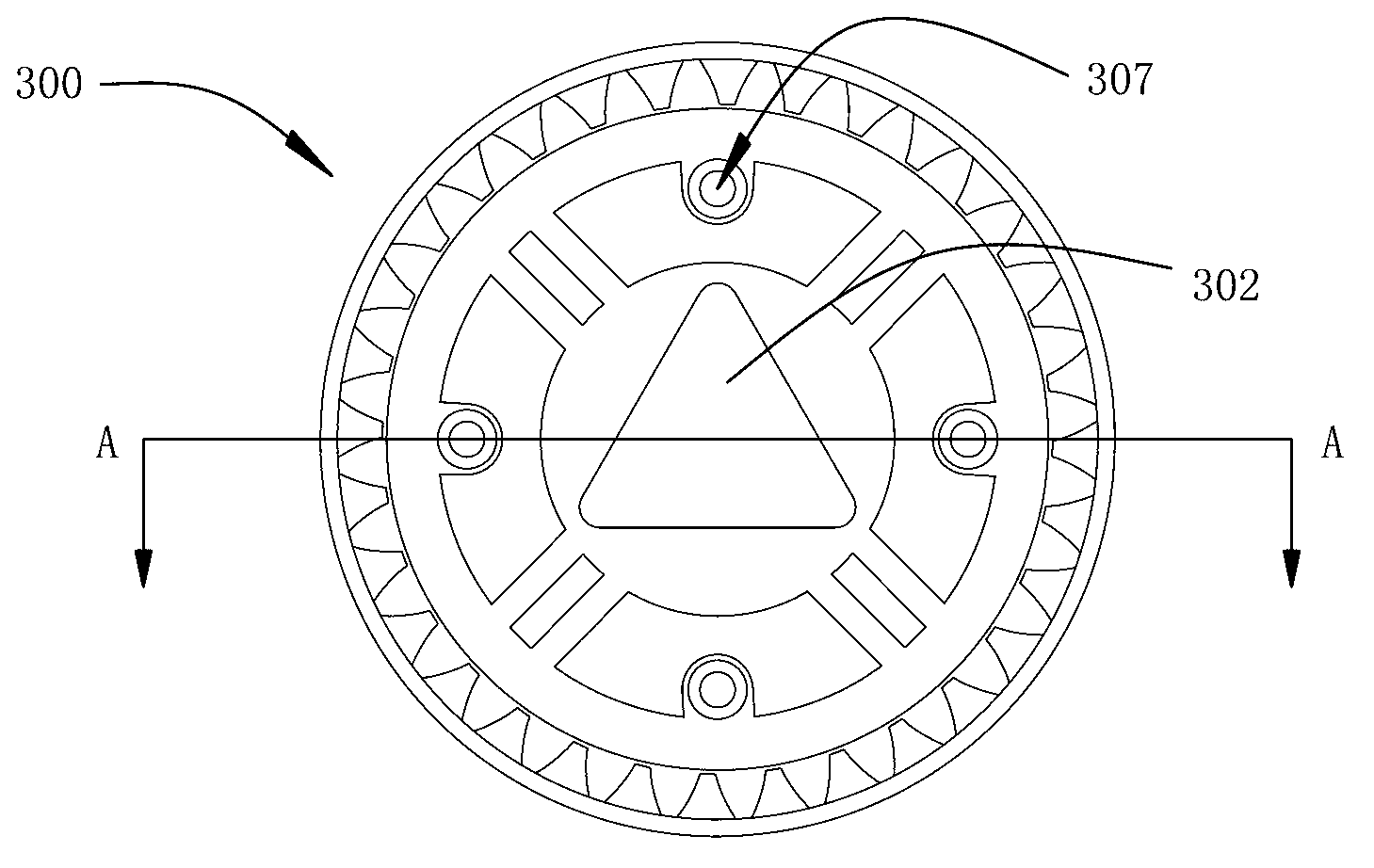

[0023] Figure 1~4 , respectively show a perspective view and a cross-sectional view of the transmission part for the photosensitive drum of the present invention from different perspective angles. Figure 5 An assembly process of the photosensitive drum 100 is shown.

[0024] see Figure 1~4 , and combined with Figure 5 .

[0025] The photosensitive drum 100 is composed of a photosensitive member 200 and a transmission member 300 .

[0026] The photosensitive component 200 adopts a hollow cylinder made of aluminum material, that is, an aluminum cylinder 201 as a basic component. A photosensitive layer 202 made of photosensitive material is coated on the outer cylindrical surface of the aluminum cylinder 201 .

[0027] The transmission part 300 is a component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com