Method for predicting hydraulic noise of centrifugal pump

A prediction method, centrifugal pump technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as prediction method, centrifugal pump rotating machinery noise prediction patent, no centrifugal pump flow-induced noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] specific implementation plan

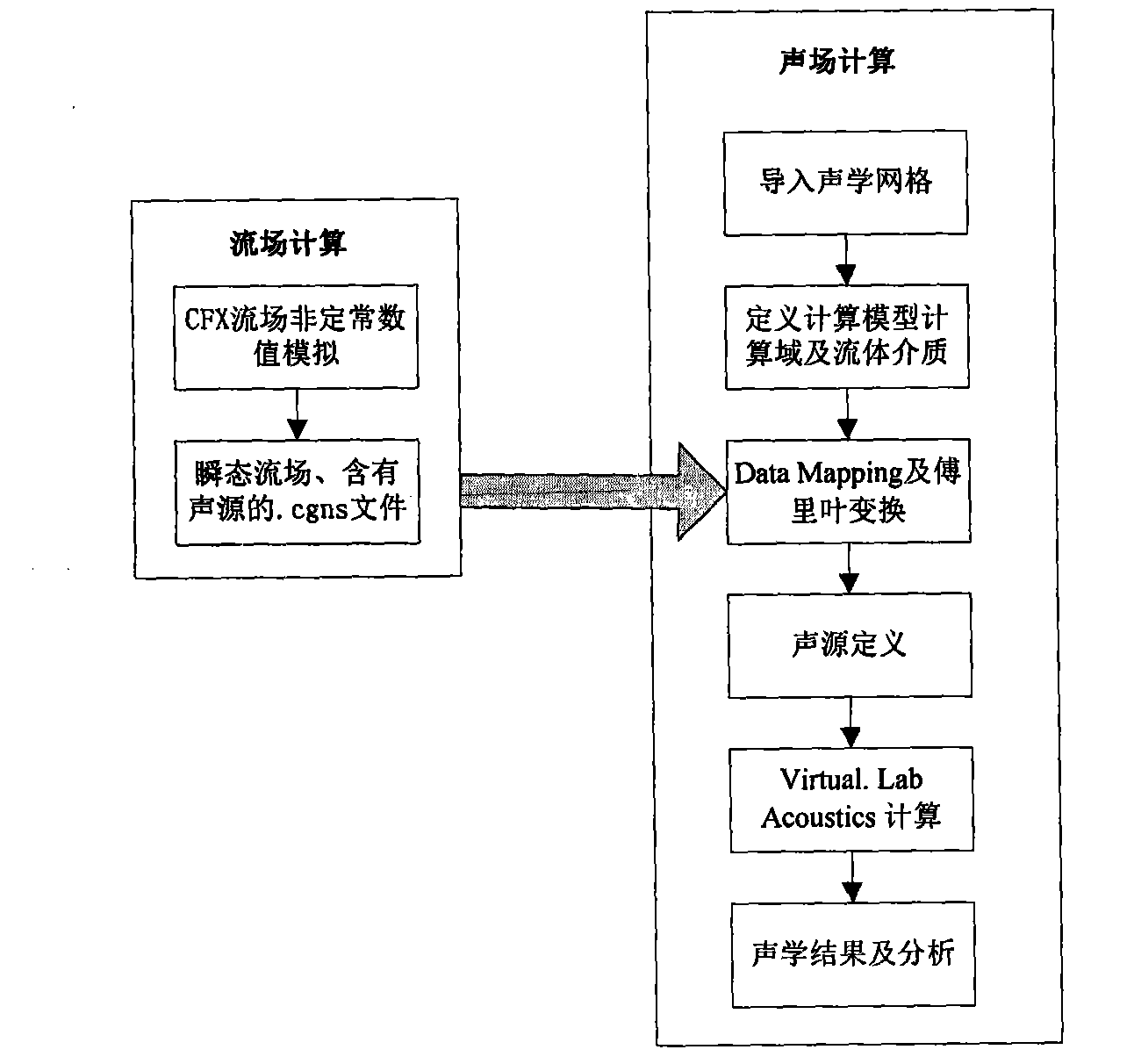

[0021] Below in conjunction with application example accompanying drawing, the present invention will be further described:

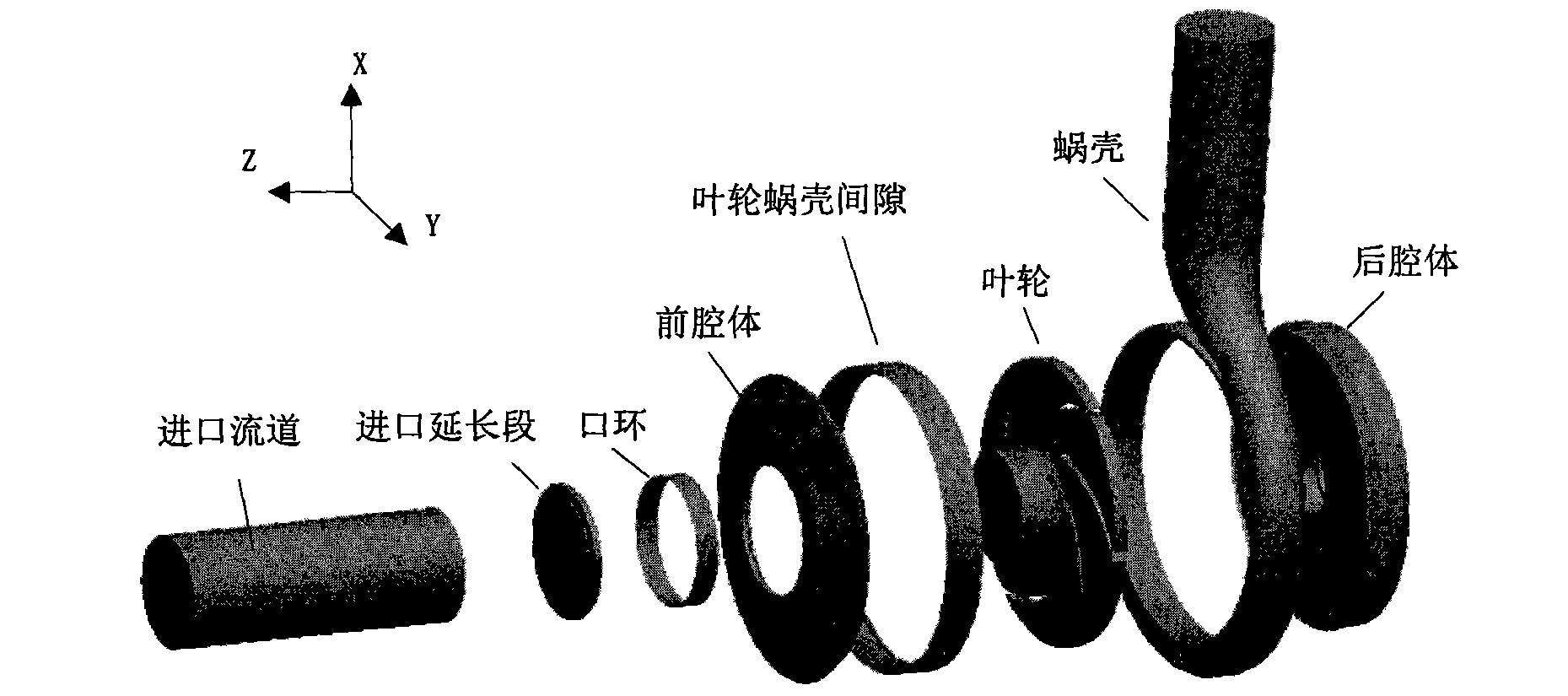

[0022] (1) Use Pro / E software to carry out three-dimensional modeling of the model pump. The full channel of the model pump is divided into eight parts: the inlet channel, the inlet extension, the mouth ring, the front cavity, the impeller, the impeller volute clearance, the volute and the rear cavity.

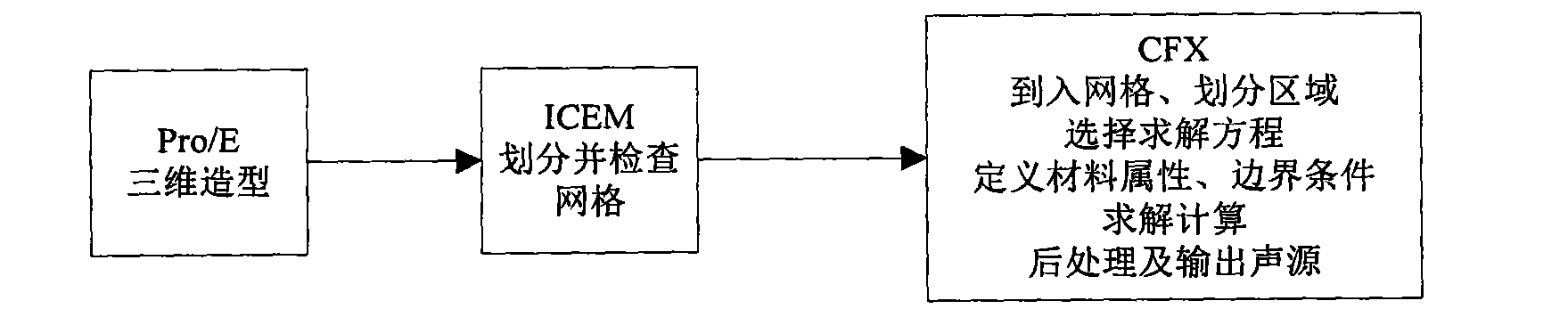

[0023] (2) This method uses ICEM to mesh the computational domain, adopts highly adaptable unstructured tetrahedral mesh for meshing, and performs local refinement on complex flow regions.

[0024] (3) Import the grid into ANSYS-CFX software, use the steady incompressible Reynolds time-averaged equation (RANS) in the rotating coordinate system, and use the SSTk-ω turbulence model to model the Reynolds stress term.

[0025] (4) Boundary conditions According to the calculation conditions, velocity inlet and pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com