Method for generating cosine differential signal

A technology of signal generation and cosine difference, applied in electric pulse generator circuits, instruments, computer control, etc., can solve problems such as complex hardware circuits, low precision, and influence of output waveforms, and achieve high precision, convenient operation, and reliability high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, the present invention will be further described:

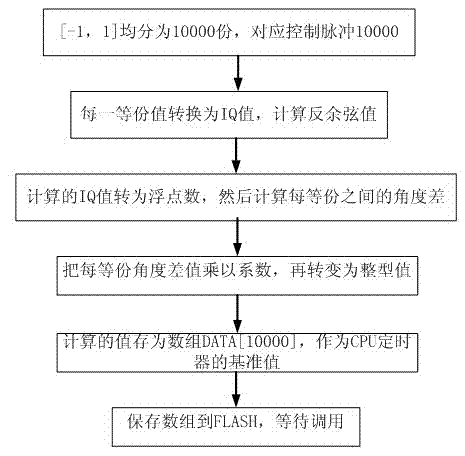

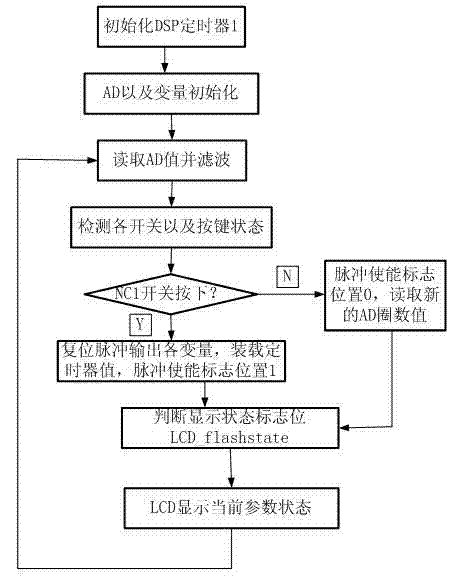

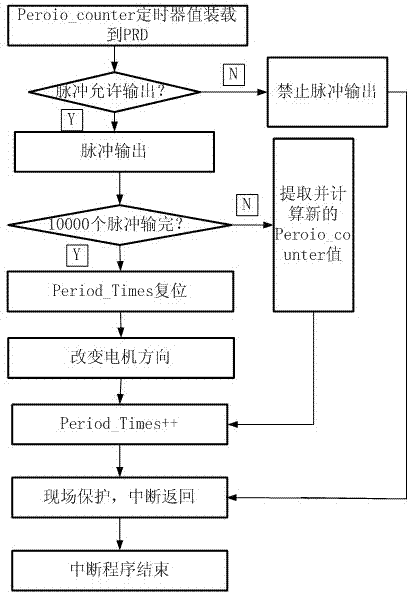

[0012] A cosine differential signal generation method, using a DSP digital signal processor to calculate the arccosine through C language programming; divide the domain value [-1, 1] into 10000 equal parts, that is, 10000 control pulses can be output in one cycle, Each equalization is converted into an IQ value, and the arccosine value is calculated according to the divided equalization value. The arccosine actually corresponds to the angle; the calculated IQ value is converted into a floating point number, and then the angle difference corresponding to each equalization is calculated, and each The equal angle difference is multiplied by a coefficient, and then converted into an integer value. The calculated value is stored as an array DATA[10000], and the array value is used as the basis for CPU timer calculation. In the program, the array value is stored in FLASH, waiting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com