Ultrasonic emulsification feeding device and feeding method for cigarettes

A technology of ultrasonic emulsification and feeding device, which is applied in the fields of application, tobacco, and tobacco preparation. It can solve the problems of multiple emulsification in the detection and evaluation, no emulsification effect, and no solution to the uniformity of incoming materials, so as to broaden the scope of use and simplify the structure. , easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

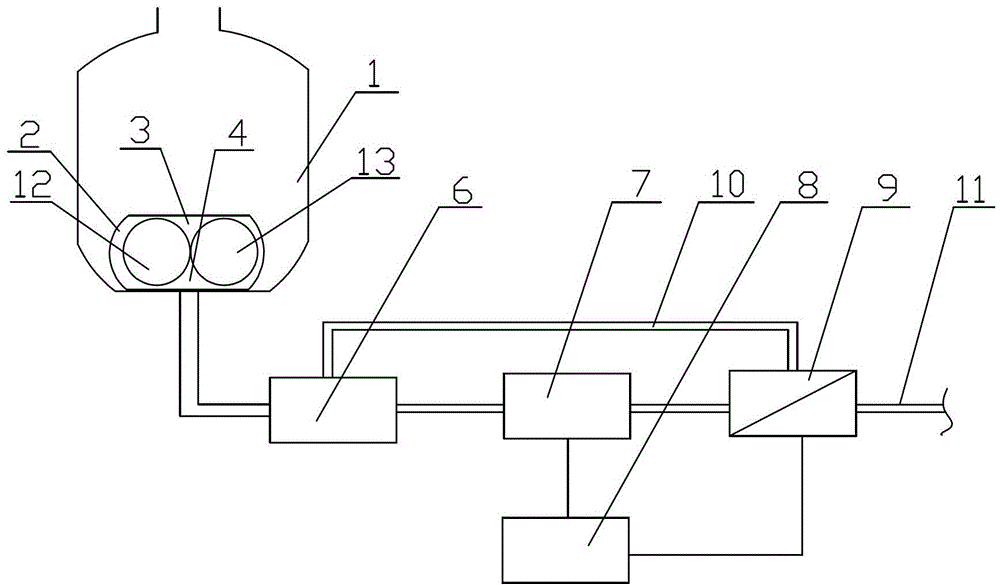

[0014] figure 1 Shown is a schematic structural view of the ultrasonic emulsification feeding device for cigarettes of the present invention, which includes a storage tank 1, a gear pump 2, a motor, an ultrasonic emulsifier 6, a particle size analyzer 7, a controller 8, a two-way valve 9, a backflow Pipe 10, discharge pipe 11.

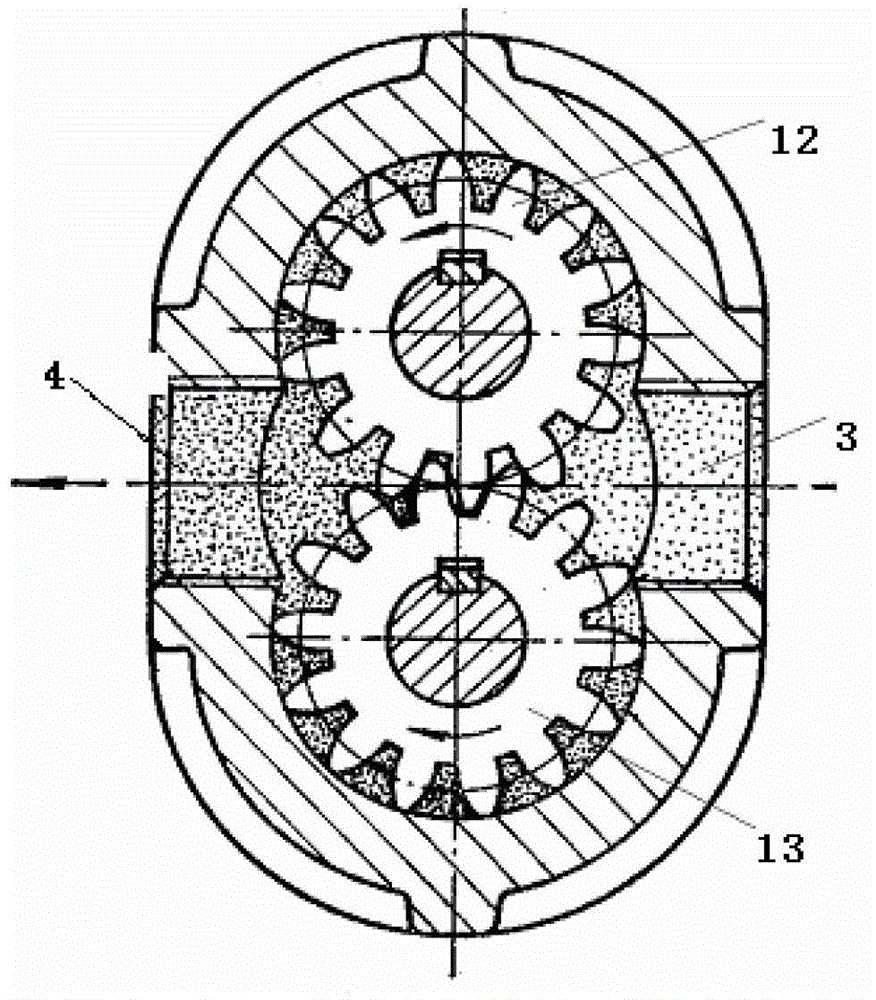

[0015] The storage tank 1 is used for storage, pre-mixing and pre-mixing of the entire batch of feed liquid; the gear pump 2 provided at the lower part of the storage tank 1 is used for stirring, pre-mixing and transporting the feed liquid. figure 2 Shown is a schematic diagram of the internal structure of the gear pump 2 in the present invention. A pair of gears 12 and 13 with the same number of teeth and a width close to the pump body and meshing with each other are installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com