Patents

Literature

34results about How to "Solve the uniformity problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

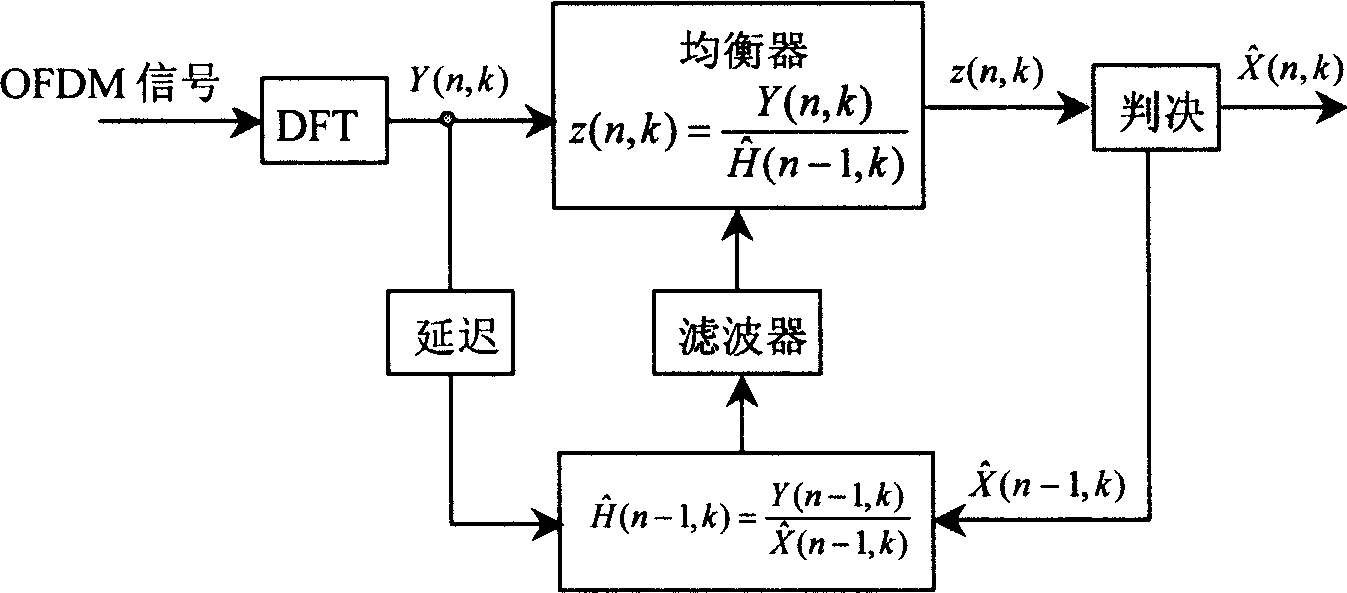

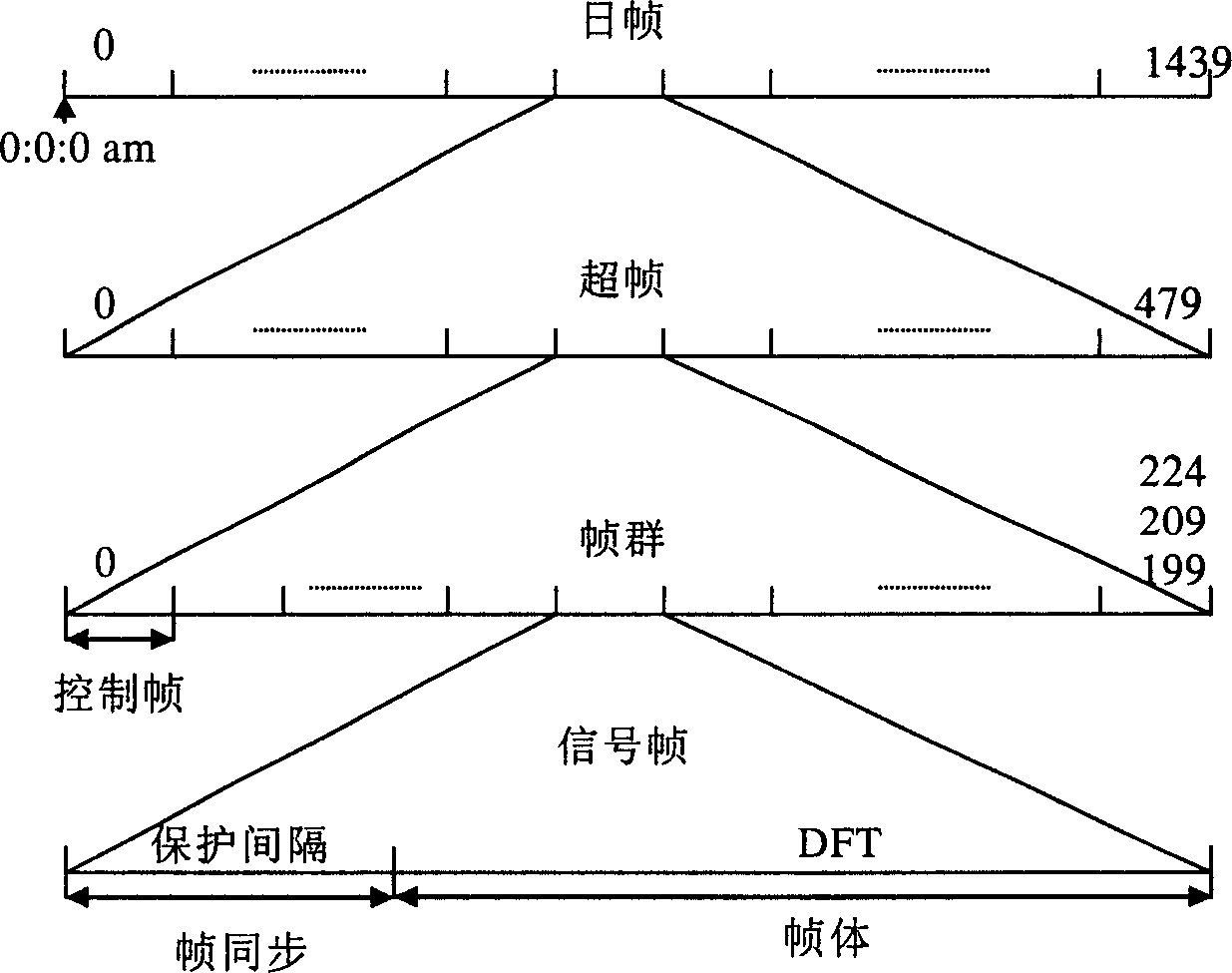

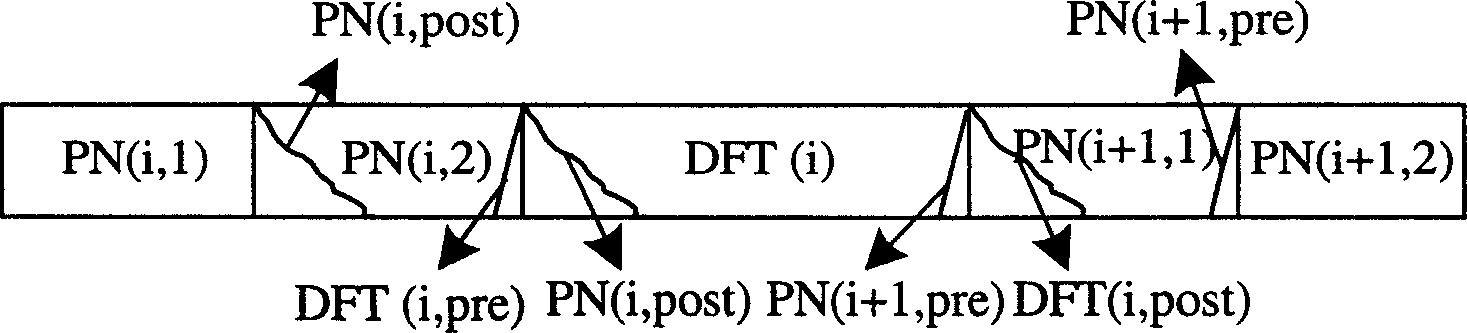

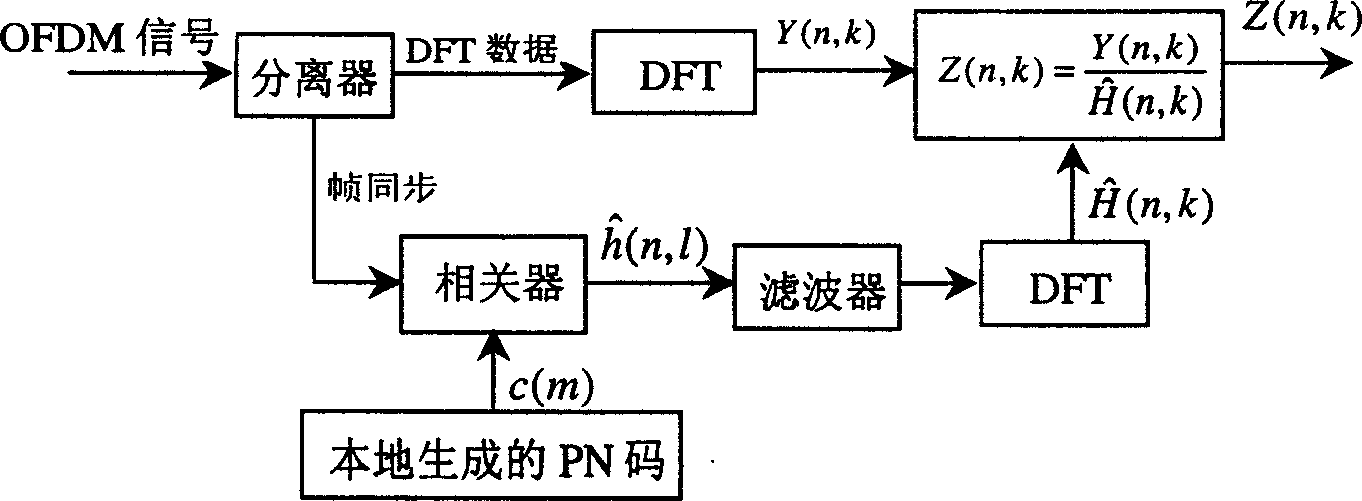

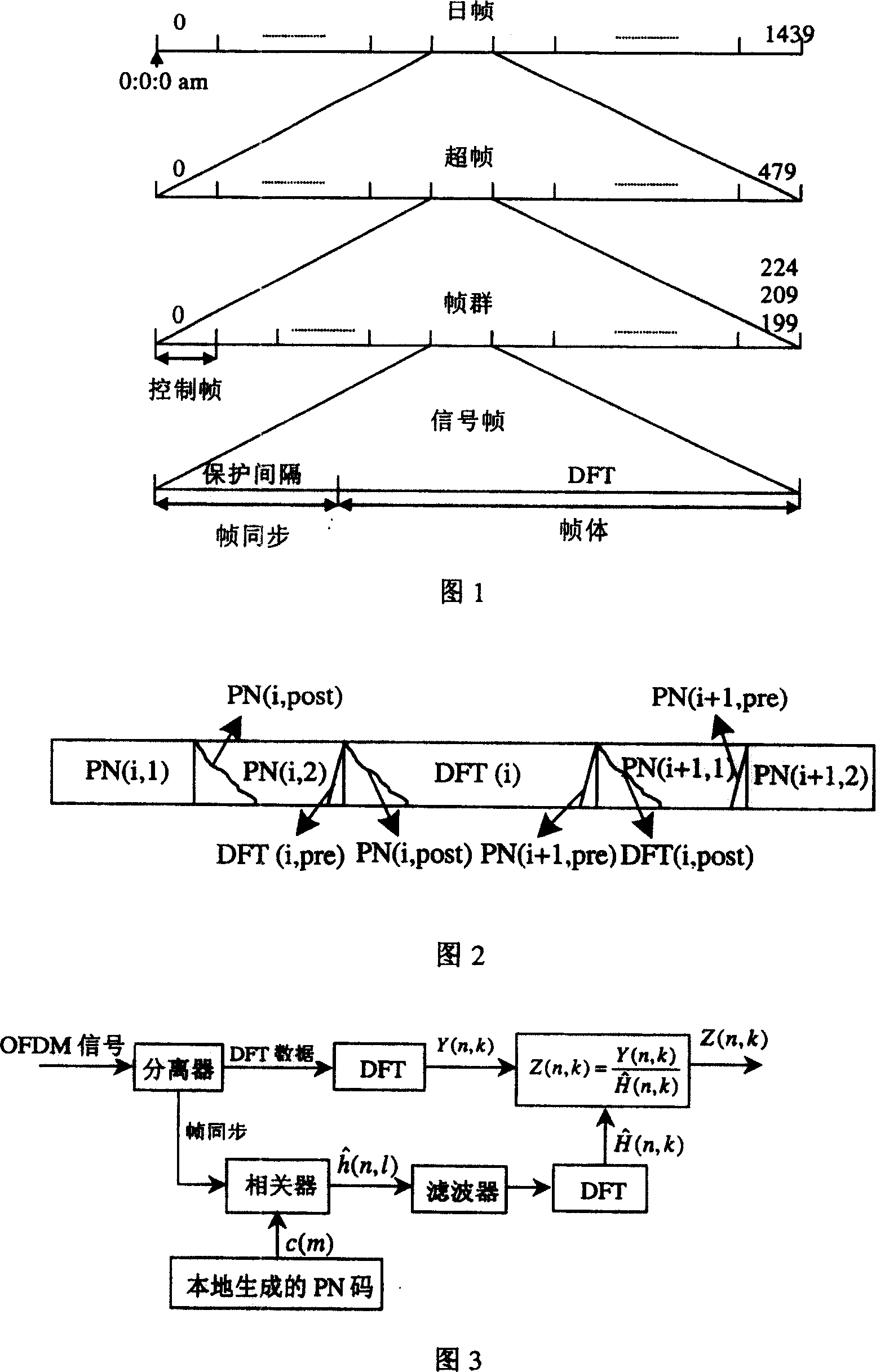

TDS-OFDM receiver self-adaptive channel estimation balancing method and system

InactiveCN1677908AAccurate estimateSolve the uniformity problemAmplitude-modulated carrier systemsOrthogonal multiplexSelf adaptiveMultipath interference

The method decomposes received TDS - OFDM signal into two parts: frame synchronization of PN code and DFT data. Based on characteristics of transmission channel, one of following methods is selected to carry out channel estimation: (1) time domain correlation method of PN code is selected, when channel possesses short time multipath disturbance; (2) frequency domain PN transformation approach is selected when channel possesses long time multipath disturbance; (3) frequency domain decision directed feedback method is selected when channel possesses stability characteristics of invariant time. The invention is realized at FPGA of Tsinghua DMB - T, ASIC version receiver. Favorable effect is obtained through actual try out broadcasting and testing, and performance is better than other system evidently.

Owner:TSINGHUA UNIV

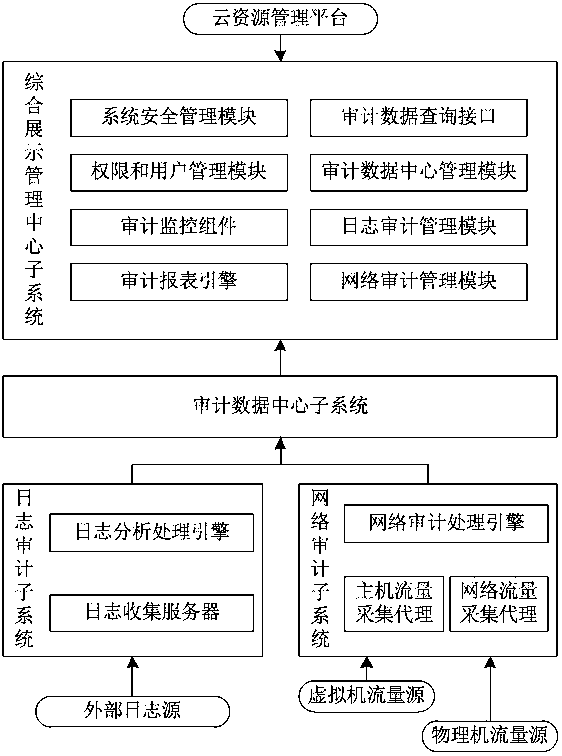

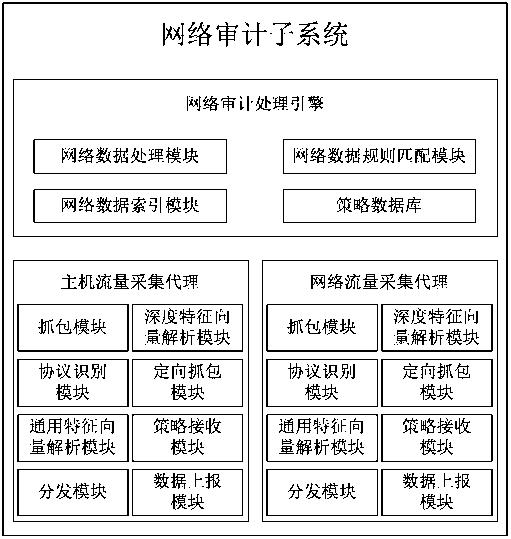

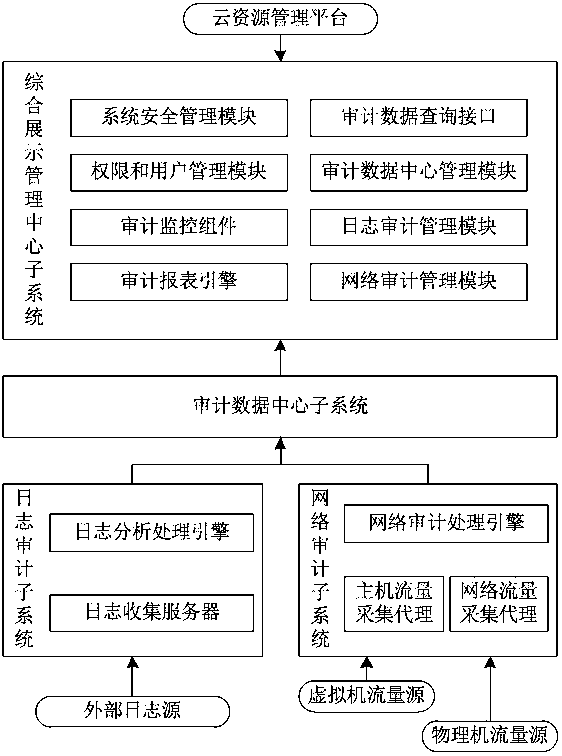

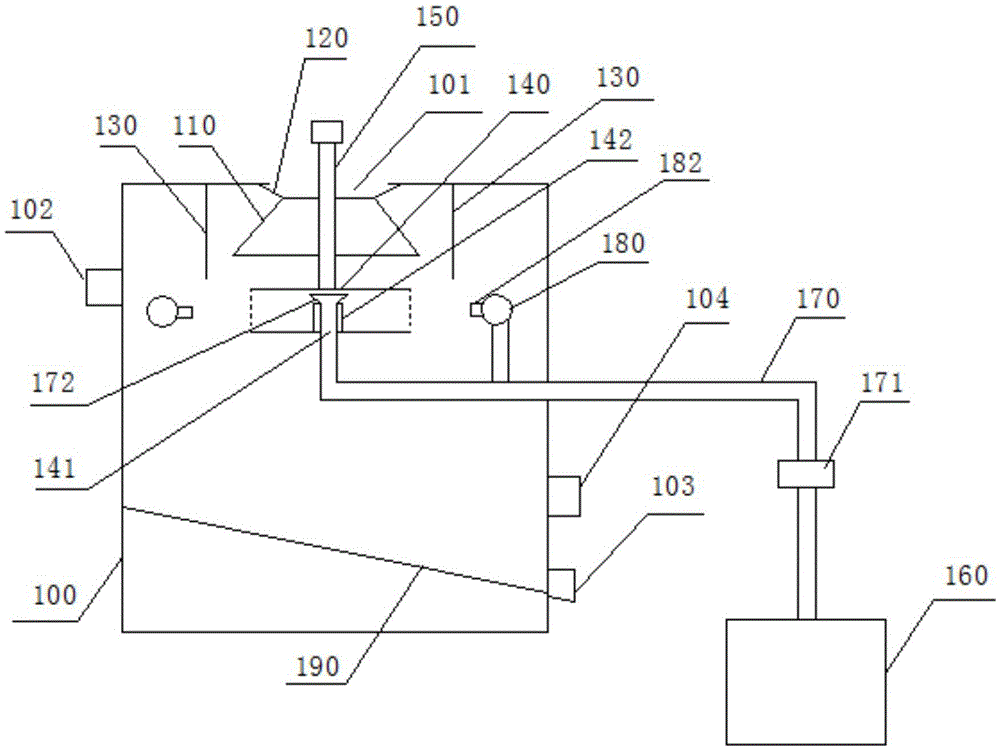

Data acquisition device applied to cloud audit system

InactiveCN107645542ASolve the uniformity problemData switching networksSpecial data processing applicationsTraffic volumeVirtual machine

The invention discloses a data acquisition device applied to a cloud audit system. The data acquisition device is upwardly connected to an audit data center subsystem of the cloud audit system and isdownwardly connected to a data source. The device comprises a log audit subsystem for acquiring log data and a network audit subsystem for acquiring network traffic data. The data acquisition device collects the log information and the traffic data generated by each virtual machine, physical machine, network device, and Hypervisor for the cloud audit system according to a rule issued by a cloud auditor. The data acquisition device provides data sources for other audit works, such as later association analysis, of the cloud audit system and is an important lower module of the cloud audit system..

Owner:CHINA SOUTHERN POWER GRID COMPANY

Algae-containing solid milky tea formula

InactiveCN103719276AReasonable priceFull of nutritionMilk preparationTea extractionInstant teaFood additive

The invention discloses an algae-containing solid milky tea formula which contains one or more of algae, such as chlorella, spirulina and haematococcaceae with the addition amount of 0.5-15 percent. According to the algae-containing solid milky tea formula, a sweetening agent, milk powder, instant tea powder, a plant extract or fruit and vegetable concentrated juice, food additives and the like are added in a blending step, and the algae-containing solid milky tea finished-product is obtained by blending, mixing, stirring, filling, sterilizing, inspecting and other procedures. The algae-containing solid milky tea formula disclosed by the invention has the characteristics of mellow mouthfeel, rich nutrition, health and environmental friendliness.

Owner:宋信宇

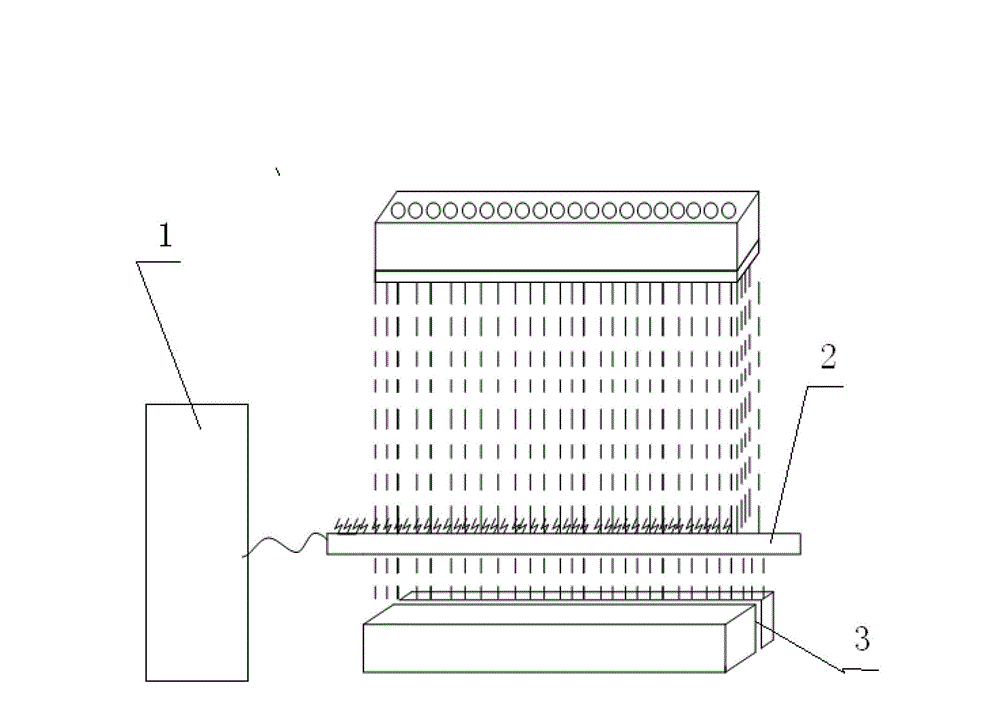

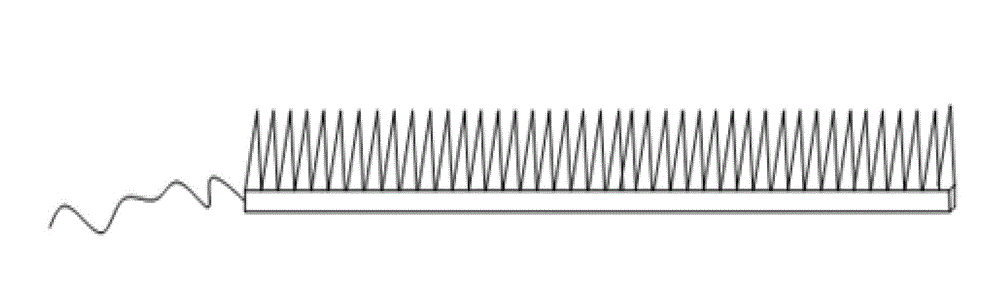

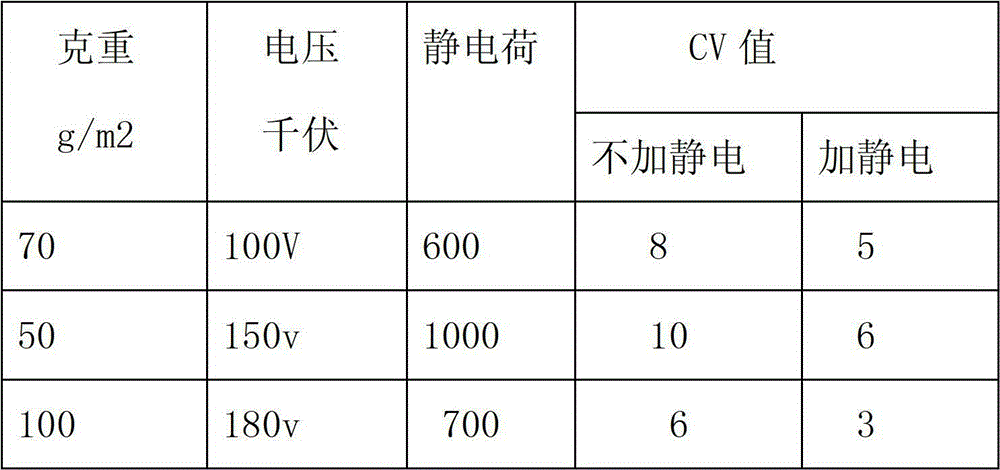

Method for improving evenness of terylene spunbonded nonwoven fabric and electrostatic filament dividing device

InactiveCN102720003ASolve the uniformity problemObvious superiorityNon-woven fabricsNonwoven fabricMelt spinning

The invention discloses a method for improving evenness of terylene spunbonded nonwoven fabrics and an electrostatic filament dividing device. The method is to apply a certain amount of positive electrostatic charge on melt-spinning cooled fibers through an electrostatic discharging rod at the entrance of a drafting device of production equipment for the terylene spunbonded nonwoven fabrics, wherein the amount of the applied positive electrostatic charge should ensure that the fibers repel each other for being charged with the same kind of charges after leaving the drafting device. An electrostatic eliminator is installed at the tail end of net curtain of a lapping machine. By adopting the technical scheme of the invention, the problem of evenness of the terylene spunbonded nonwoven fabrics, a problem that people have long been hoping earnestly to solve, is solved, and especially to terylene spunbonded nonwoven fabrics of less than 100 grams per square, the advantage is more obvious.

Owner:SHANDONG TAIPENG ENVIRONMENTAL PROTECTION MATERIAL

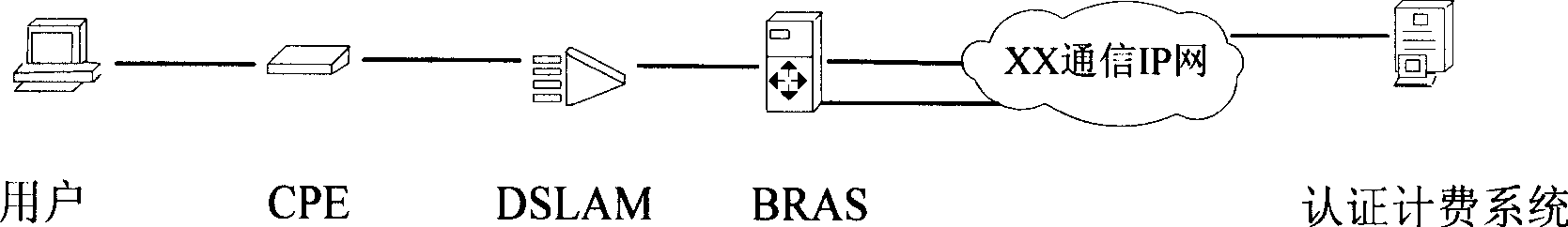

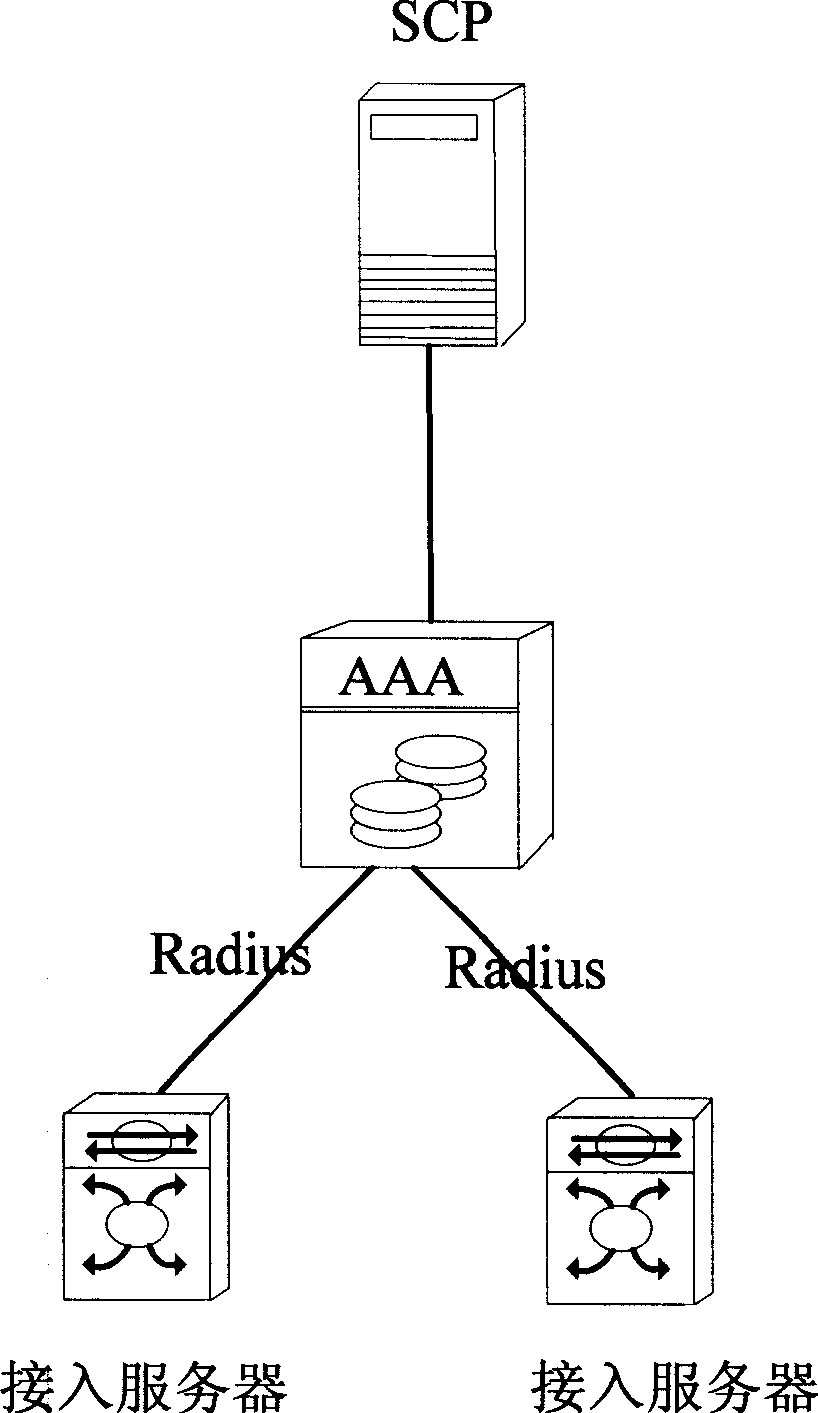

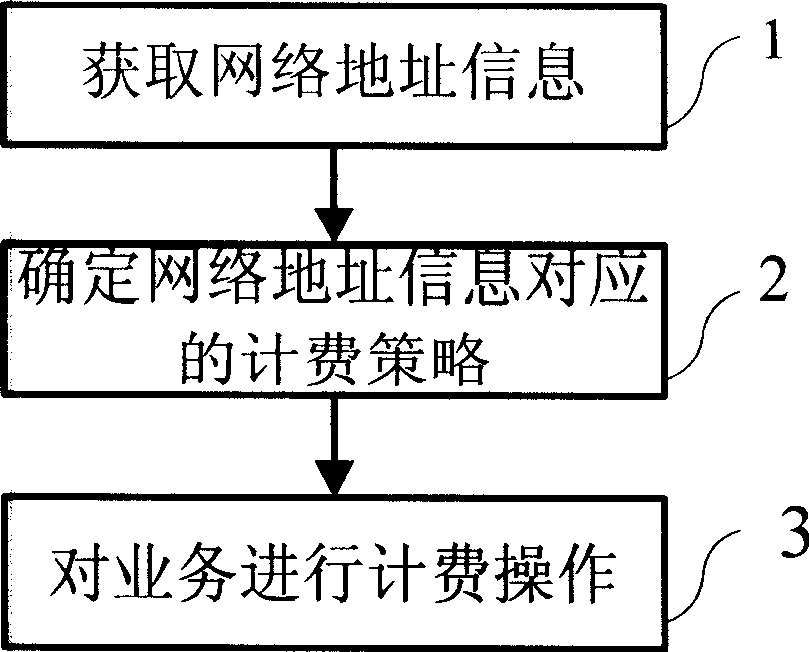

Fee charging method and system

InactiveCN101499912AMeet billing requirementsSolve the uniformity problemMetering/charging/biilling arrangementsTime segmentNetwork addressing

The invention discloses a charging method and a charging system, and the specific charging method comprises the following steps: network address information used by the business which is started in a network is obtained; a business charging strategy corresponding to the network address information is determined and utilized for realizing charging operation of the business. By adding the charging based on the network address information as another charging way, the embodiment of the invention can implement different charging ways for different network address information, and can consequently satisfy the requirement for realizing charging according to business values and related time sections of data amounts in downtown districts, realizes charging according to different application scenes, and solve the problem of balanced and reasonable system resource usage by utilizing the adjusting effect of charging to the system resource usage.

Owner:HUAWEI TECH CO LTD

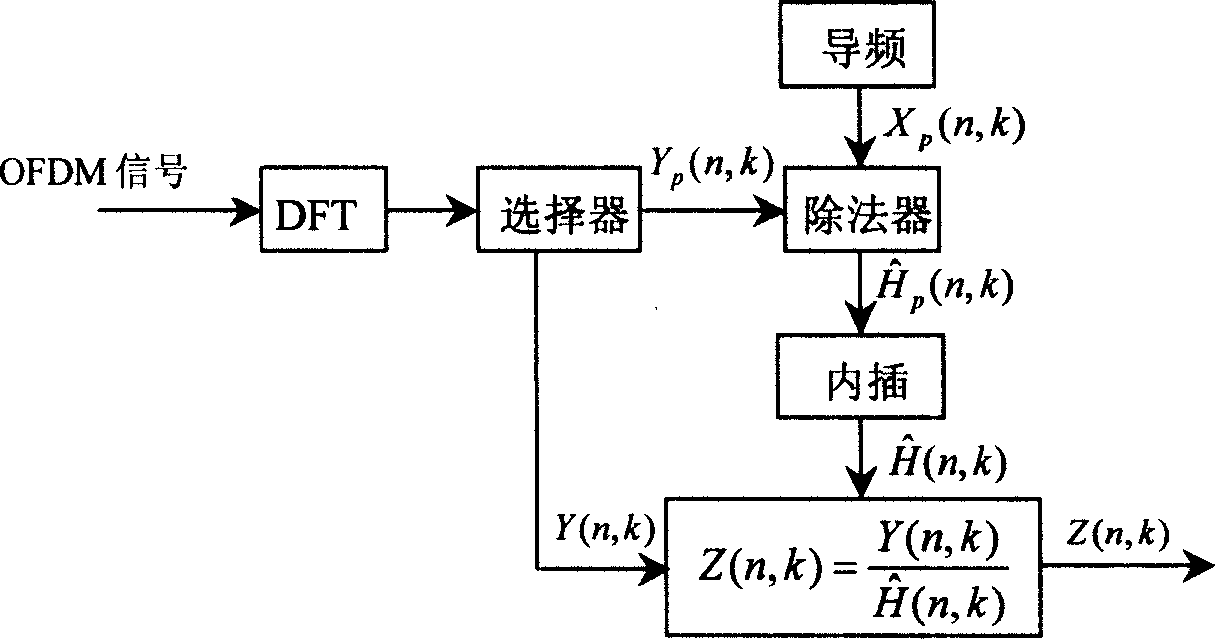

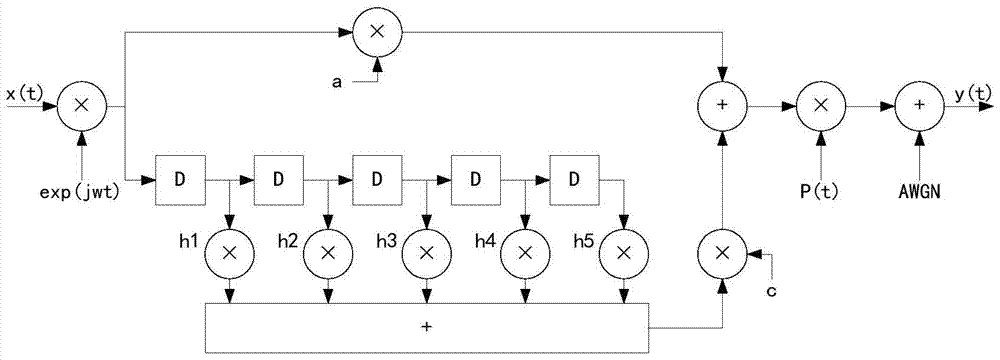

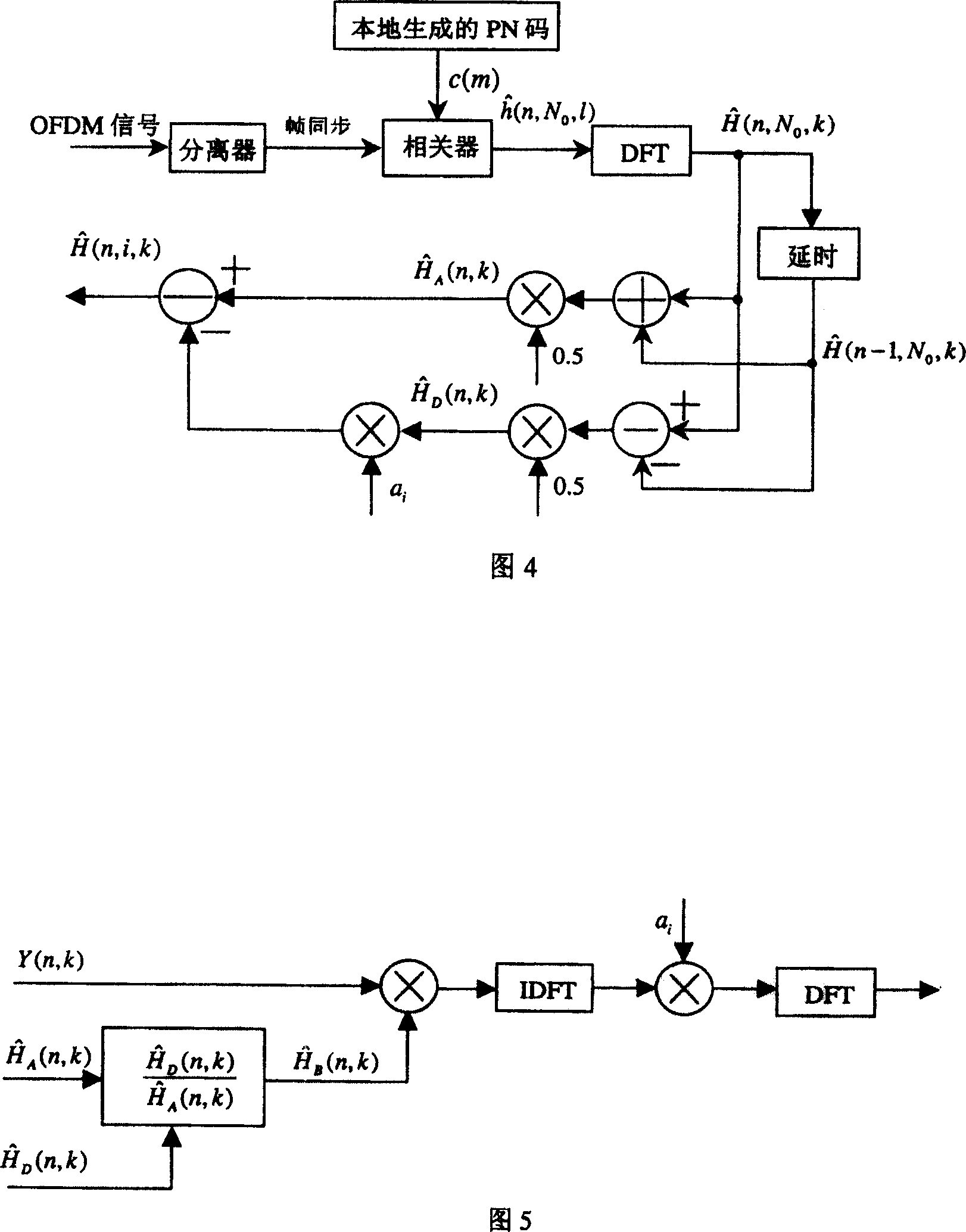

Time-varying channel evaluation and equalizing method and system for TDS-OFDM receiver

InactiveCN1617531ASolve the uniformity problemImprove robustnessMulti-frequency code systemsTime domainEngineering

This invention relates to TDS-OFDM receiver time-varying channel estimation and the balance method and system which assumes the channel varies in linearity in an OFDM block. Firstly a channel response estimation at the PN of each OFDM block is got by PN code time domain then to carry out linear interpolating in the OFDM block to get the entire channel response estimation. This invention puts forward a simplified balance method for complementing the balance matrix with ICI to carry out spreading of finite item power series, which greatly increases the receiving performance of TDS-OFDM receivers under time-varying channel and is better than the scheme of assuming the channel unchanged in an OFDM block.

Owner:TSINGHUA UNIV

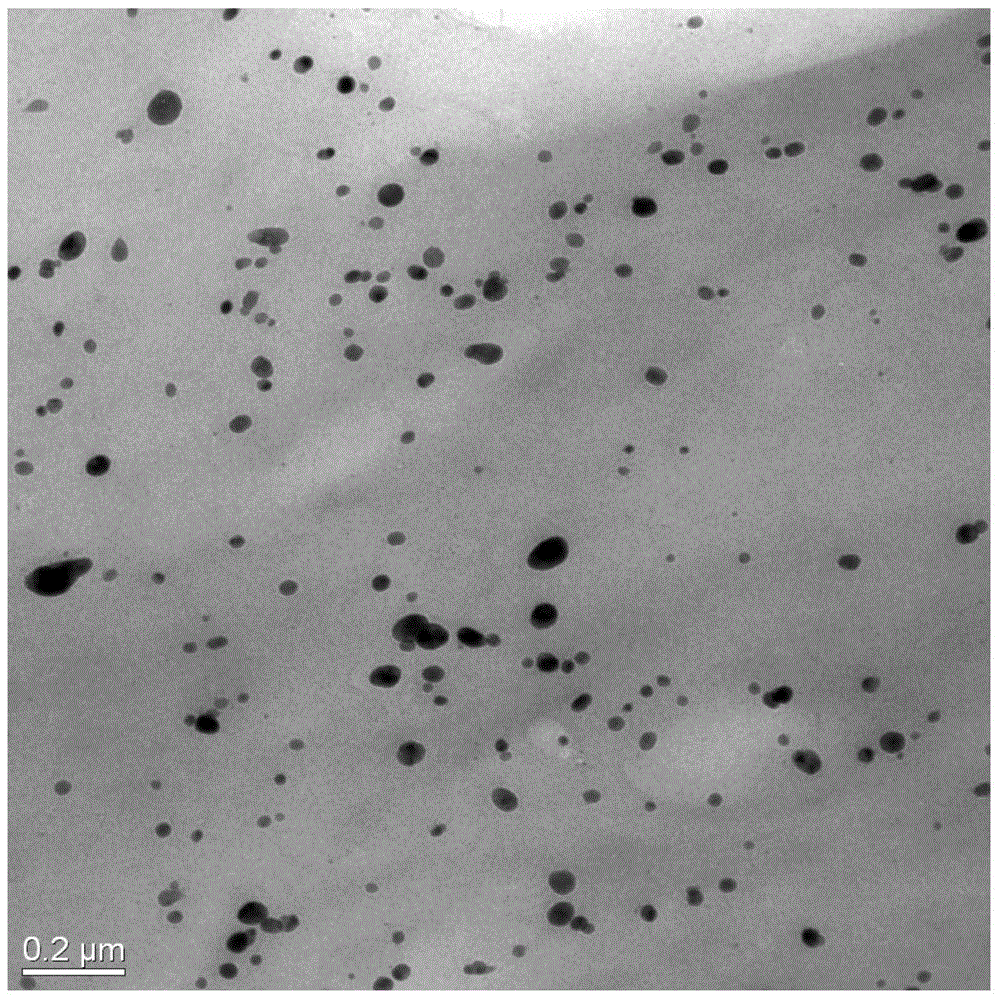

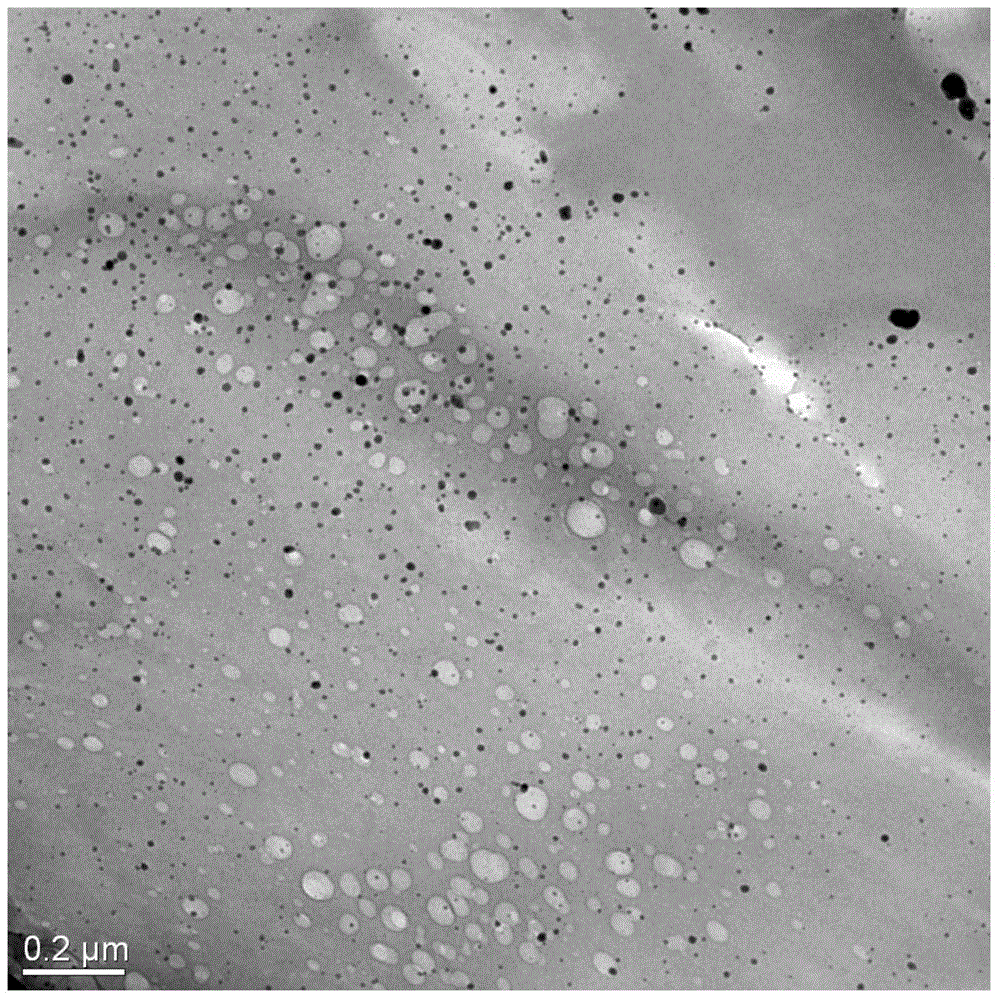

Nano-silver composite antibacterial cellulose membrane, and preparation method and application thereof

The invention discloses a nano-silver composite antibacterial cellulose membrane, and a preparation method and an application thereof. The preparation method comprises the following steps: (1) a cellulose membrane is prepared with uniformly dispersed nano / micron cellulose; (2) a silver nitrate solution is uniformly sprayed onto a membrane substrate, and the membrane substrate is wetted until saturated; (3) water in the wetted and saturated membrane substrate is removed with a physical method, wherein the membrane substrate is not completely dried; (4) a reducing agent solution is sprayed onto the membrane substrate obtained in the step (3), until the membrane substrate is completely impregnated; and (5) when color is completely changed, the membrane substrate is taken out; the taken-out membrane substrate is washed and the washed membrane substrate is dried, such that the nano-silver composite antibacterial cellulose membrane is obtained. The preparation method provided by the invention is simple. With the method, nano-silver loading amount and distribution are easy to control. The nano-silver has the advantages of small size, uniform dispersion, good antibacterial effects, good bonding strength, and high stability. The original quality of the nano or micron cellulose is not influenced. The prepared membrane is suitable to be applied in the fields such as traumatic wound, medical care and antibacterial packaging.

Owner:GUANGDONG IND TECHN COLLEGE

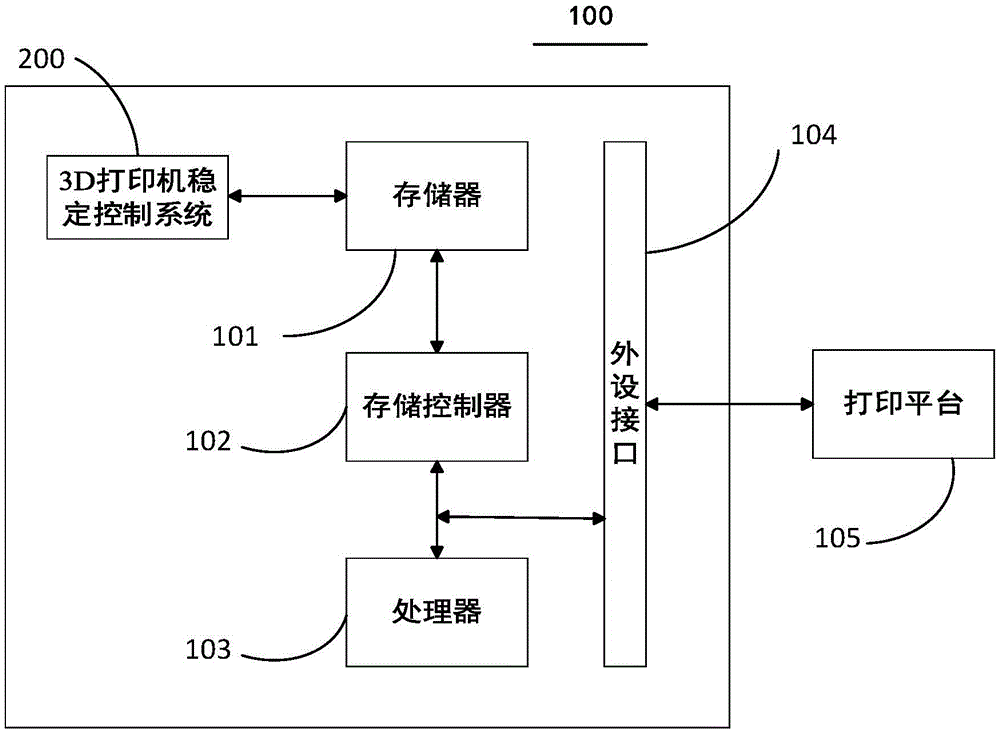

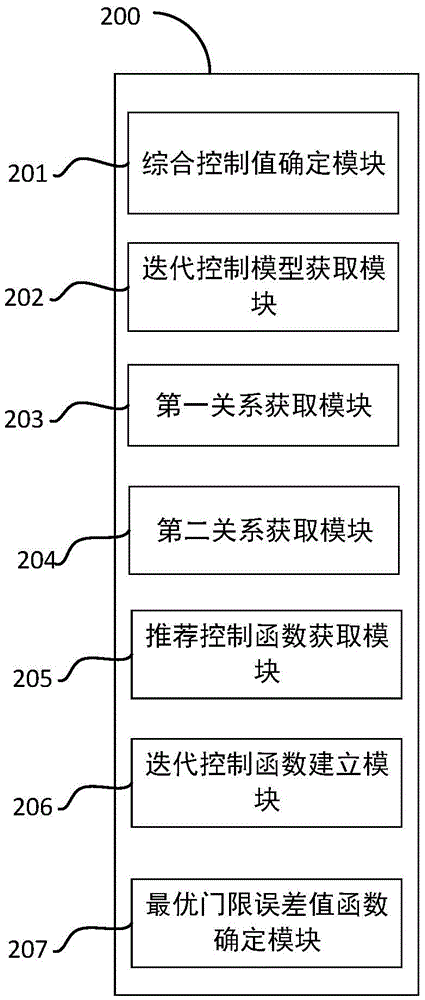

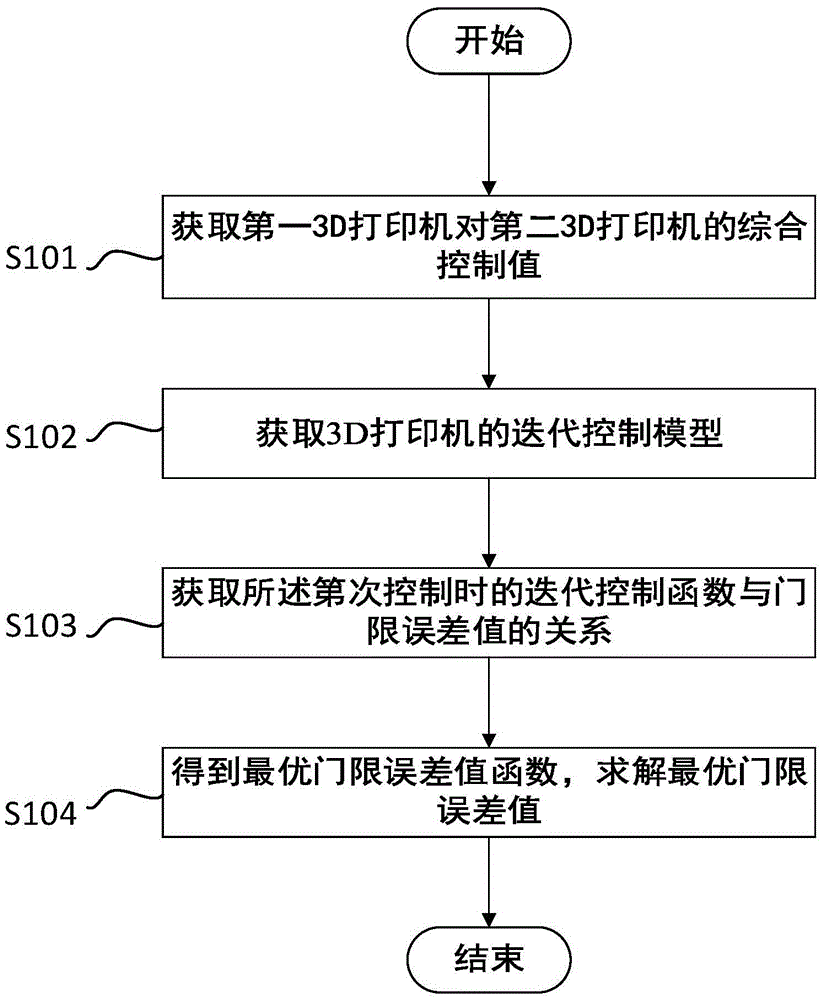

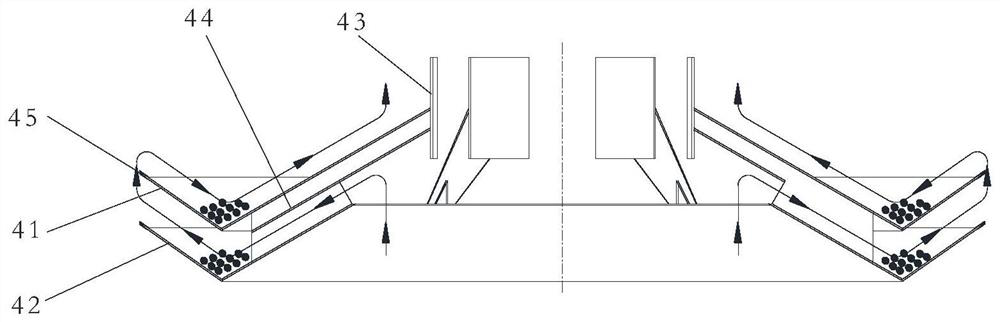

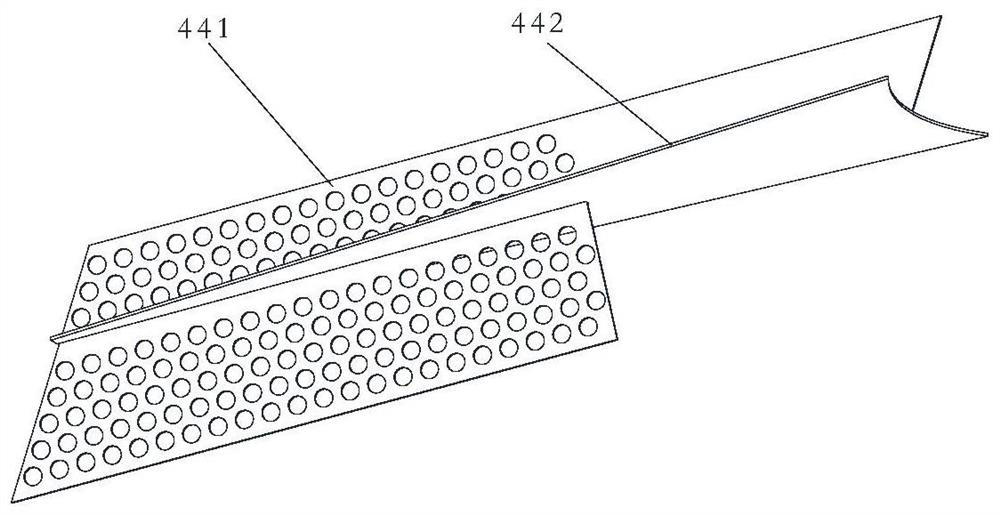

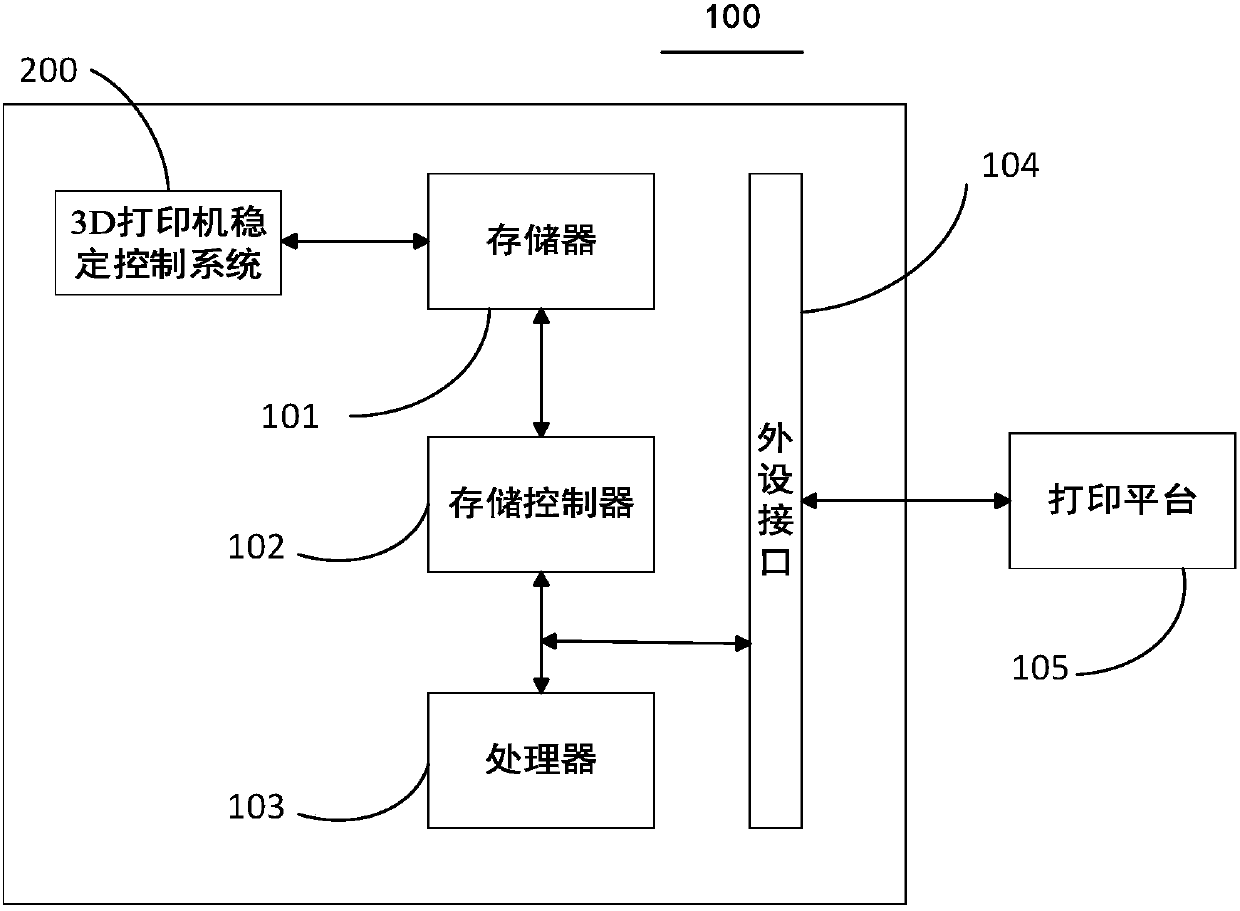

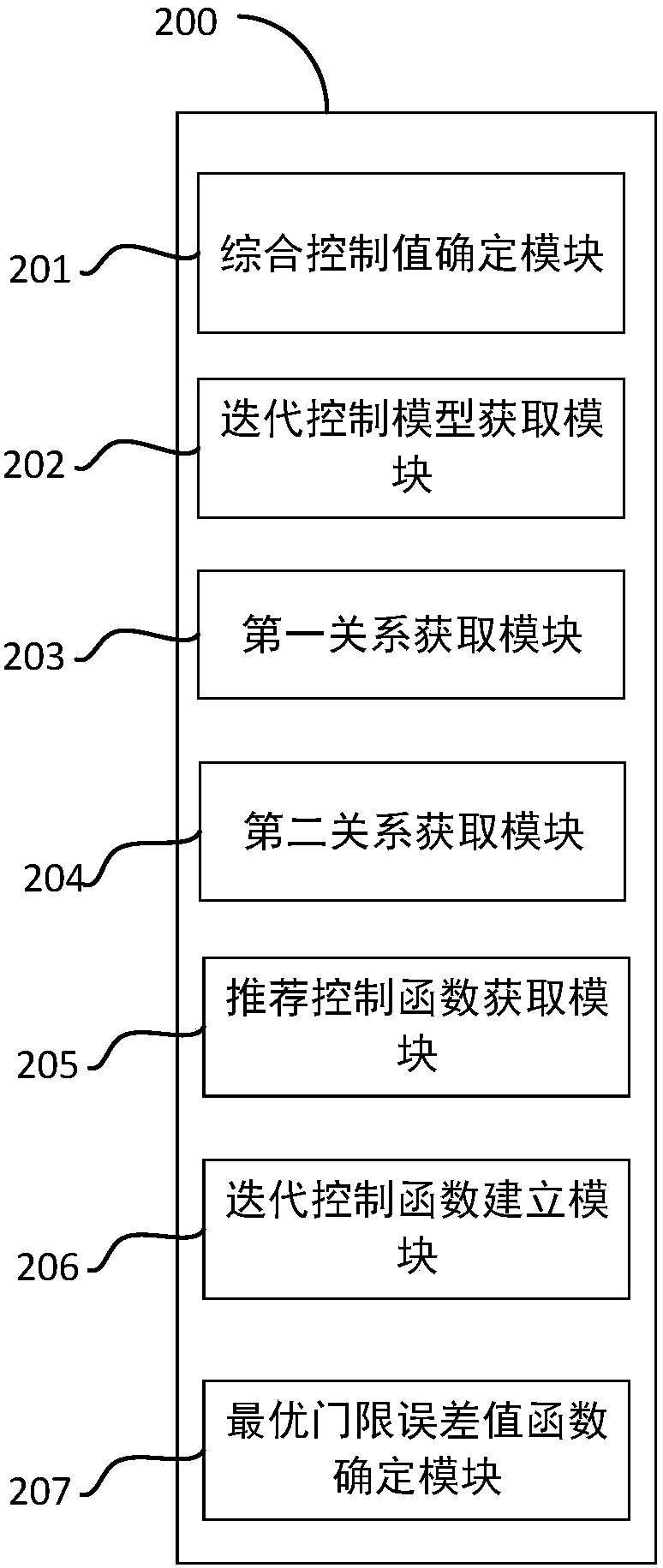

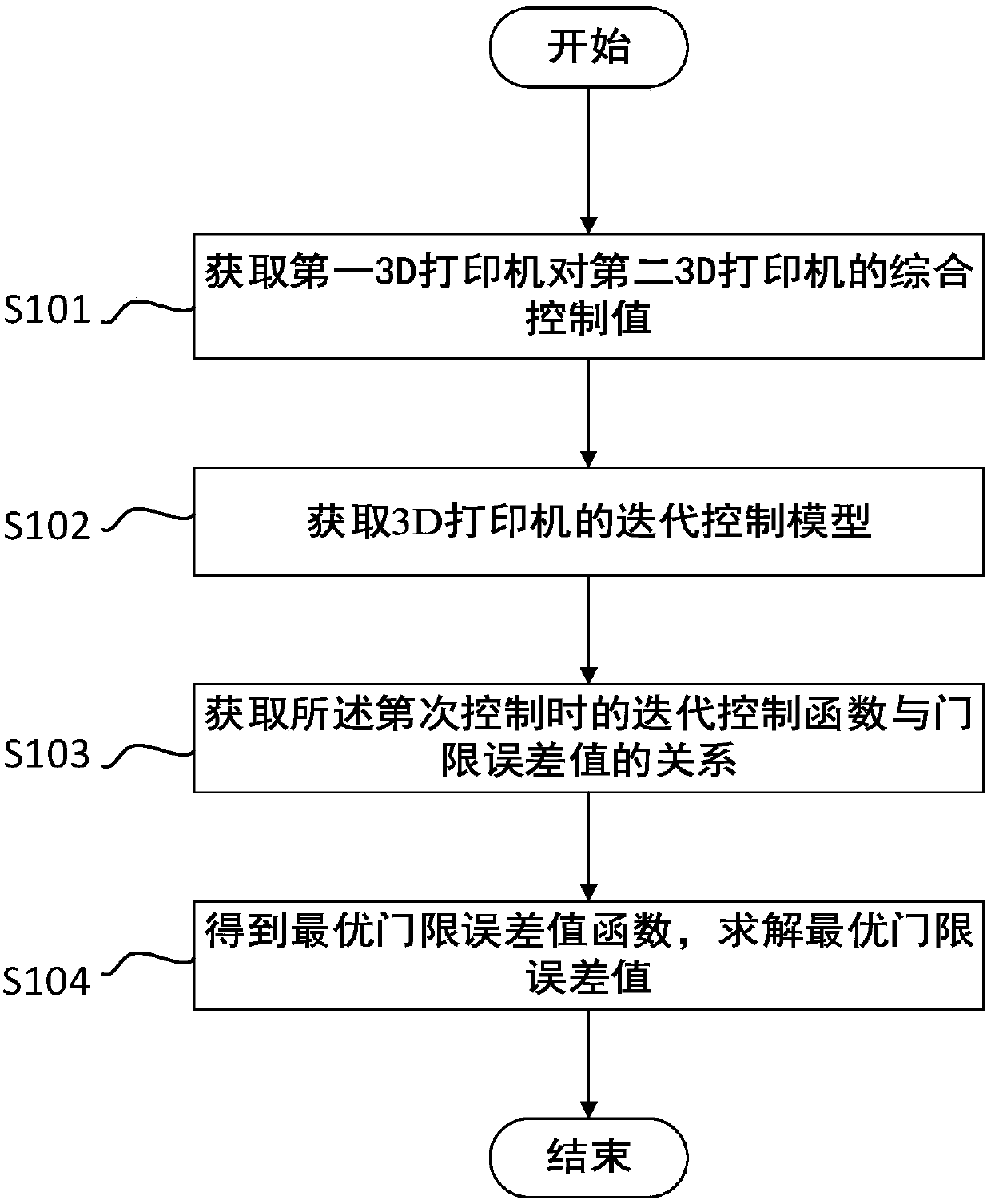

3D Printer stability control method and control system

ActiveCN105643944AImprove stabilitySolve the uniformity problemAdditive manufacturing apparatusUltrasound attenuationControl system

An embodiment of the invention provides a 3D printer stability control method and a control system and relates to the technical field of three-dimensional printing. The 3D printer stability control method comprises: acquiring a comprehensive control valve of a first 3D printer module for a second 3D printer module, acquiring an iterative control module of the 3D printer to obtain a relation between an iterative control function and a threshold error value during ith (I being a positive integer greater than 0) control, further acquiring an optimal threshold error value function, and solving an optimal threshold error value. In the 3D printer stability control method and the control system of the invention, by constructing the optimal threshold error value model and by selecting the optimal threshold error value in real time through an attenuation integral balance point of recommended control valves, it is possible to well solve the problem that recommended control valves of a forming process of a 3D printer experience a balance and imbalance attenuation along with changes in a threshold value and to improve the stability of the printer.

Owner:三维泰柯(厦门)电子科技有限公司

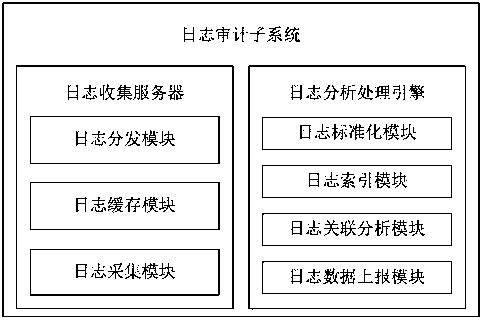

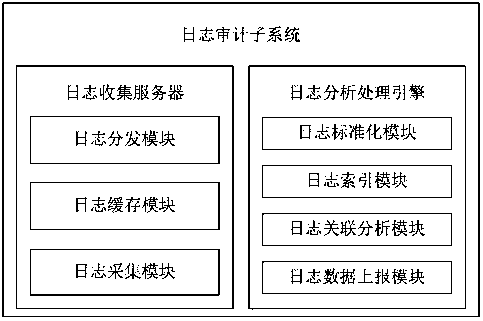

Log audit subsystem applied to cloud audit system

InactiveCN107656973ASolve the uniformity problemFile access structuresSpecial data processing applicationsData centerCorrelation analysis

The invention discloses a log audit subsystem applied to a cloud audit system. The subsystem includes a log collection server and a log analysis processing engine. The log collection server also includes a log collection module, a log cache module and a log distribution module. The log analysis processing engine also includes a log standardization module, a log index module, a log correlation analysis module and a log data reporting module. The log collection server is responsible for collecting, caching and distributing log data from various sources. The log analysis processing engine is responsible for carrying out standardization, correlation analysis and persistent storage on collected logs. The log analysis processing engine carries out correlation analysis on the logs, then carries out changing storage on the logs to an externally connected audit data center subsystem, standardizes the logs, and adopts flow-type computing technology such as storm for concurrent processing to support distributed deployment.

Owner:CHINA SOUTHERN POWER GRID COMPANY

Carbon sequestration enzyme synergistic water soluble fertilizer and preparation method thereof

InactiveCN105523847AUniform particlesStable physical and chemical propertiesAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersMonopotassium phosphateBiological activation

The invention discloses carbon sequestration enzyme synergistic water soluble fertilizer and a preparation method thereof. The carbon sequestration enzyme synergistic water soluble fertilizer is prepared from the following components in parts by weight: 4.8-57 parts of urea, 0-65 parts of monopotassium phosphate, 10-75 parts of potassium nitrate, 0-58.5 parts of ammonium dihydrogen phosphate, 0-55 parts of potassium sulphate, 1-3 parts of micronutrient fertilizer, 0.25-2 parts of carbon sequestration enzyme, 0.2-0.75 part of surfactant and 0.2-2 parts of chelating agent. The fertilizer prepared by the method supplements nutrients needed by crops, and enhances photosynthesis; because of the mutual promotion of the carbon sequestration enzyme and nutrient elements, ground crop growth, soil improvement and microbial activation supplement each other.

Owner:SHANDONG SENHE BIO TECH CO LTD

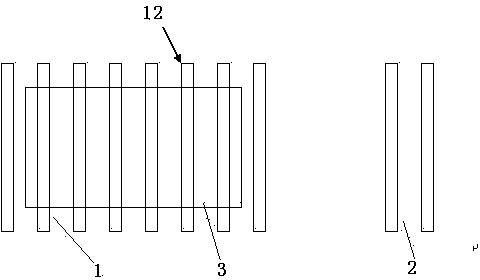

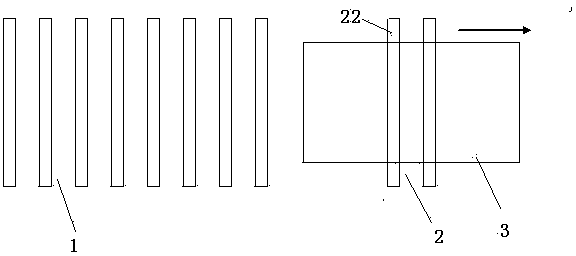

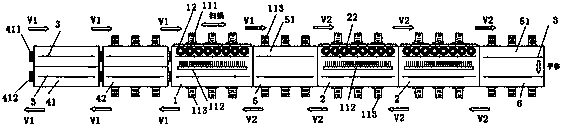

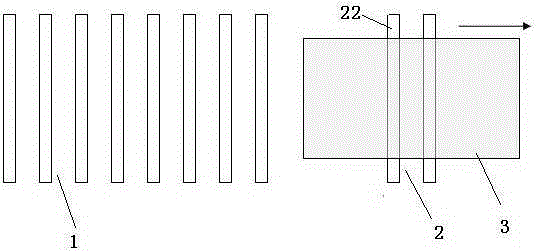

Dynamic/static hybrid coating system and dynamic/static hybrid coating method by utilization of dynamic/static hybrid coating system

ActiveCN103993273AAvoid electrostatic damagePlay the role of electrostatic shieldingVacuum evaporation coatingSputtering coatingComing outCoating system

The invention relates to a coating system and a coating method, especially to a dynamic / static hybrid coating system and a dynamic / static hybrid coating method by the utilization of the dynamic / static hybrid coating system. The dynamic / static hybrid coating system comprises a static coating system and a dynamic coating system. The static coating system contains a static coating chamber, a first coating assembly and a first transmission assembly. The reciprocating scan distance is zero or any distance less than the spacing between adjacent target materials. The dynamic coating system contains a dynamic coating chamber, a second coating assembly and a second transmission assembly. The dynamic / static hybrid coating method contains two modes. The first mode is as follows: static coating comes first and dynamic coating follows; then vertical transition of a substrate is conducted and the substrate comes out in a reverse direction; and the substrate is uncoated after translation. The second mode is as follows: the substrate firstly enters the innermost chamber; static coating is conducted after vertical transition; then, the substrate comes out in a reverse direction for dynamic coating; and finally, the substrate comes out from a low vacuum chamber. By the system and the method, a substrate can be coated and coating is uniform. Electrostatic damage to an electrostatic sensitive device can be prevented.

Owner:ZHEJIANG SHANGFANG ELECTRONICS EQUIP

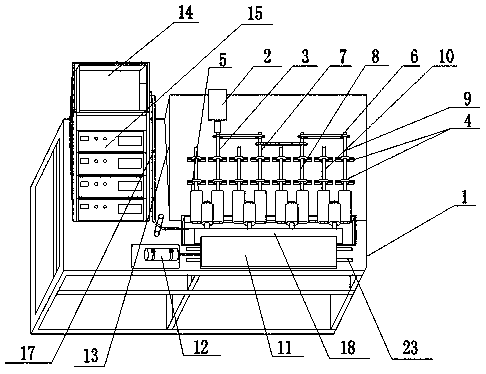

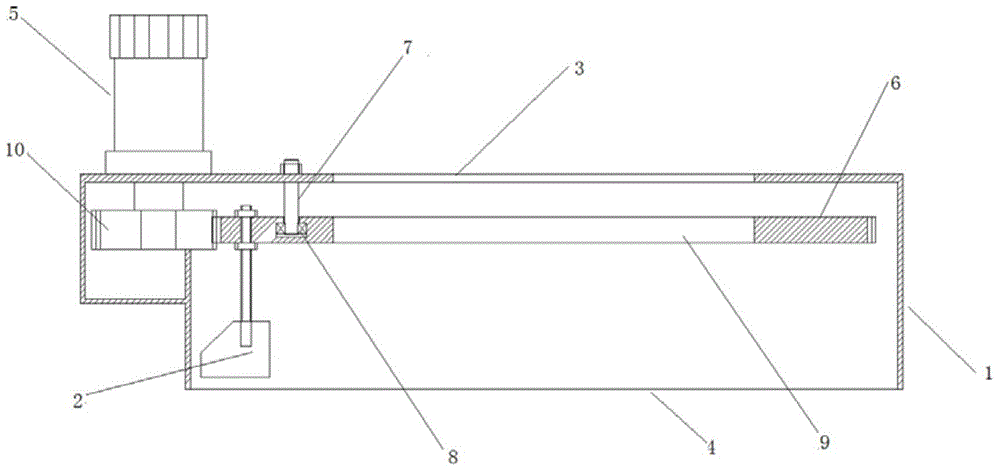

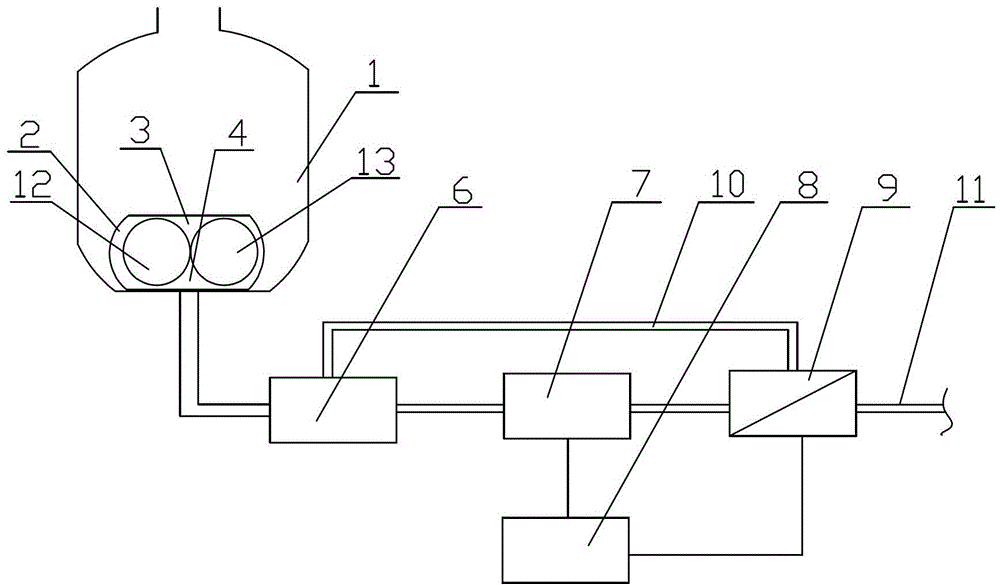

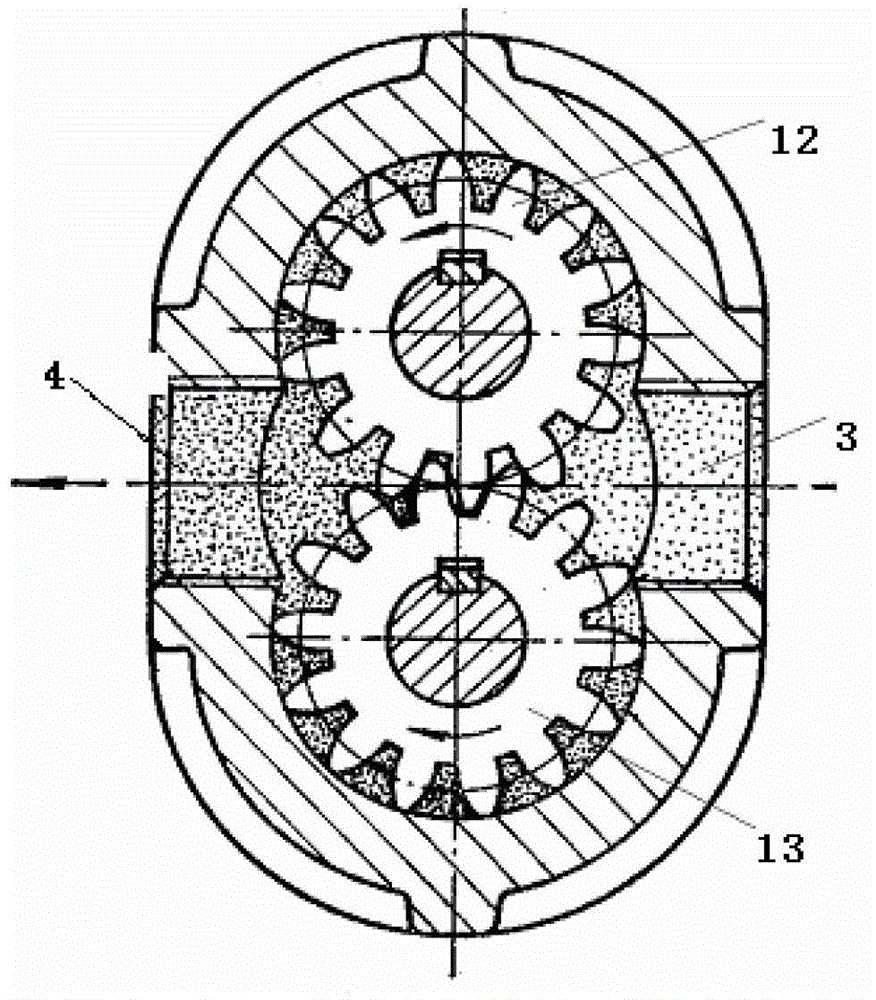

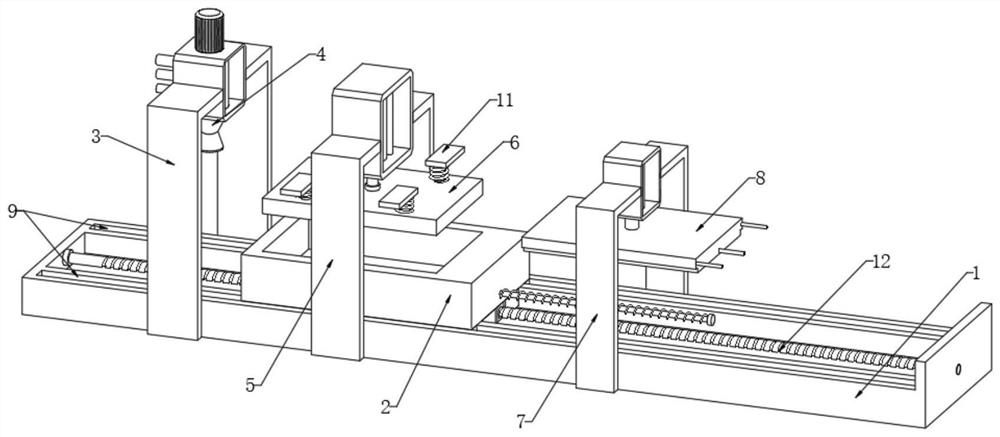

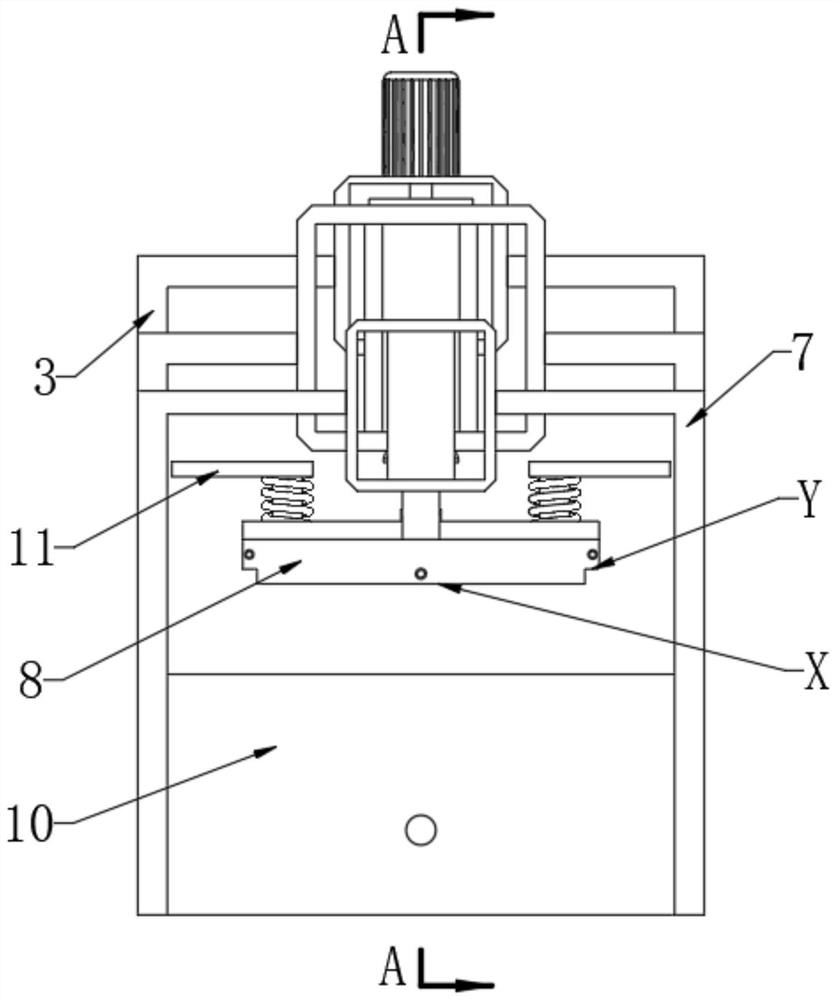

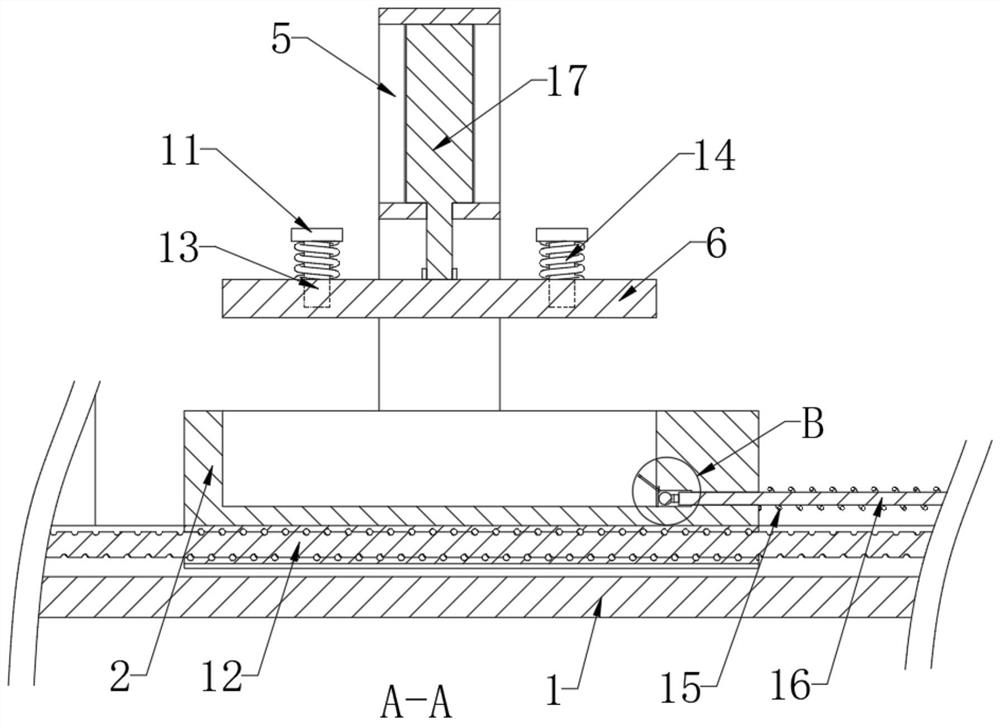

Automatic brushing and plating machine

The invention provides an automatic brushing and plating machine which comprises a table body (1). A drum table board (13) is arranged on the table body (1). A speed change motor (2) is arranged on the drum table board (13). The power output end of the speed change motor (2) is connected with a first driving bearing rod (3). The first driving bearing rod (3) penetrates through a bearing pedestal (4) and is connected with a drum (5). A bevel angle of 15-20 degrees is formed between the drum (5) and a plane of the table body (1). According to the automatic brushing and plating machine, the drumtable board and the horizontal plane are installed in the manner of forming the angle of 15-20 degrees, and the face of a brushing plate and the drum are installed vertically. The drum structure drives a pipe to rotate, when the pipe rotates in an inclining manner, the downward gravity causes the pipe to move downwards to make close contact with the brushing plate, on one hand, the problem that due to acting force in the brushing and plating process, the pipe retreats is avoided, on the other hand, electric contact between the pipe and the brushing plate is good, electrifying is smooth, the thickness of a plating layer is uniform, and the effect of the uniform degree of the pipe is achieved.

Owner:中国振华电子集团宇光电工有限公司(国营第七七一厂)

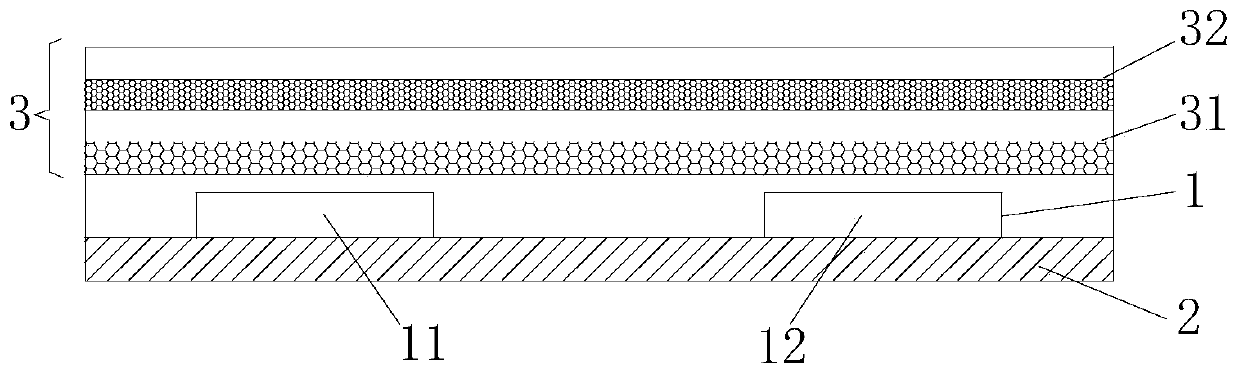

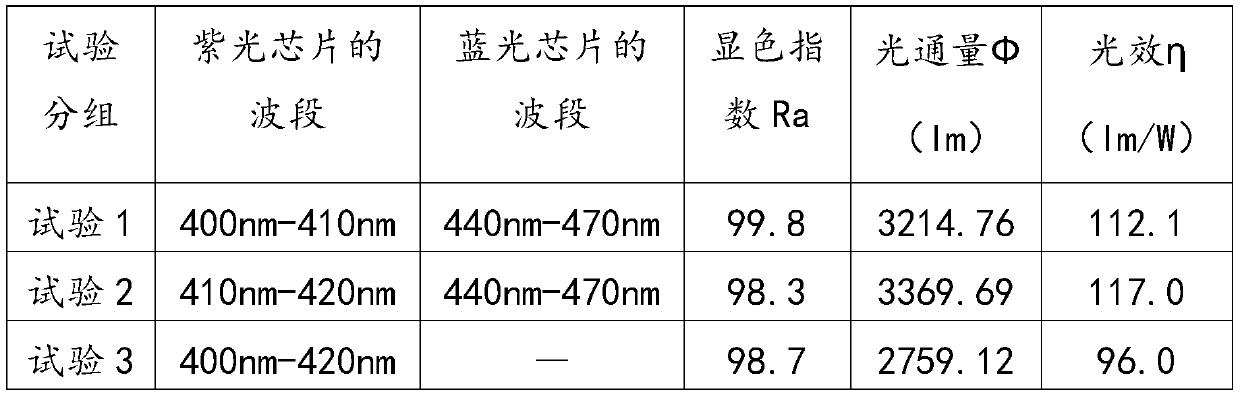

Full-spectrum LED lamp bead

PendingCN110880494ARich in spectral componentsReduce the phenomenon of luminous rate dropSolid-state devicesSemiconductor devicesEpoxyGreen yellow

The invention discloses a full-spectrum LED lamp bead which comprises a light-emitting chip, a support used for containing the light-emitting chip and fluorescent glue used for packaging the light-emitting chip and allowing light emitted by the light-emitting chip to be transmitted and emitted out. The light-emitting chip comprises a blue light chip and a purple light chip. The wave band of the blue light chip is 440 nm to 470 nm, and the wave band of the purple light chip is 400 nm to 420 nm. The fluorescent glue is formed by mixing silica gel or epoxy resin glue with fluorescent powder. Thefluorescent powder comprises red fluorescent powder, yellow-green fluorescent powder and blue fluorescent powder. The excitation wave band of the red fluorescent powder is 615 nm to 660 nm, the excitation wave band of the yellow-green fluorescent powder is 520 nm to 540 nm, and the excitation wave band of the blue fluorescent powder is 445 nm to 455 nm. The lamp bead has the advantages of low energy consumption, high color rendering index and high brightness, is more beneficial to human health and environment, and is closer to sunlight.

Owner:GUANGDONG LCLED LIGHTING

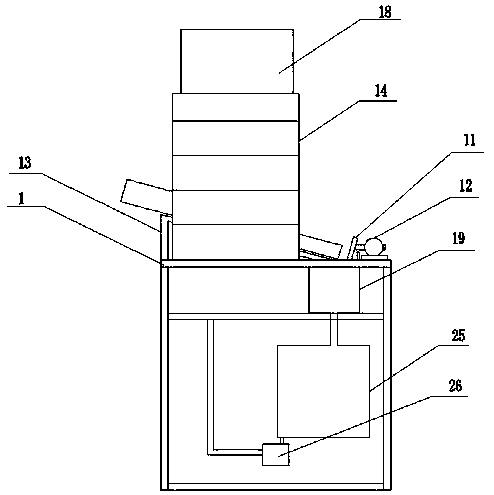

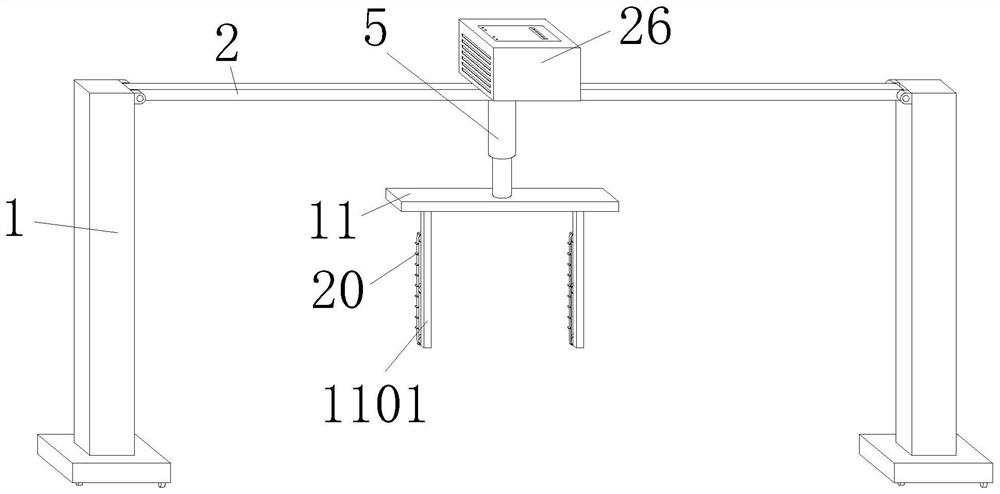

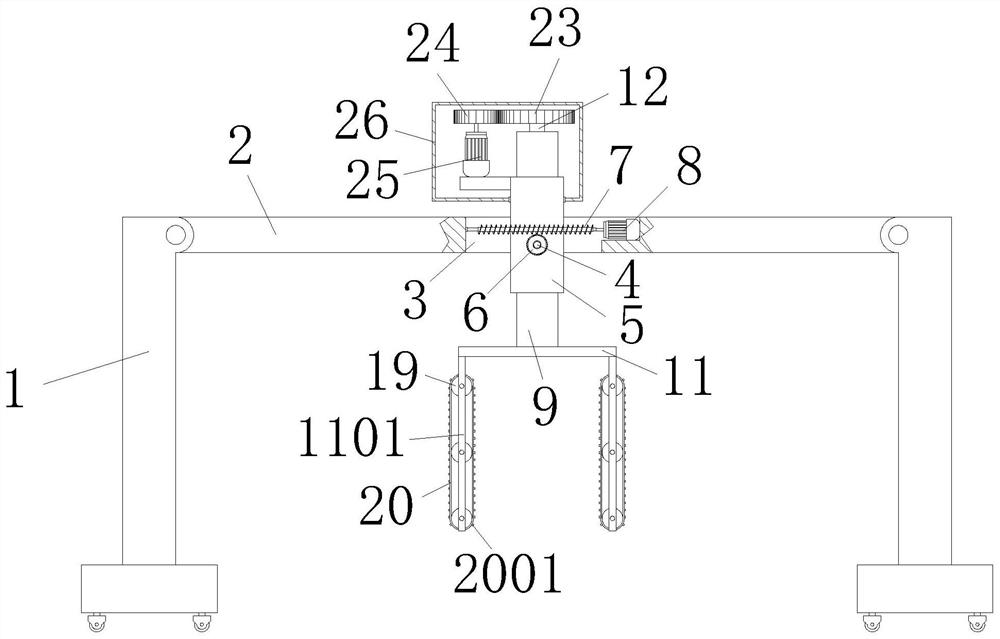

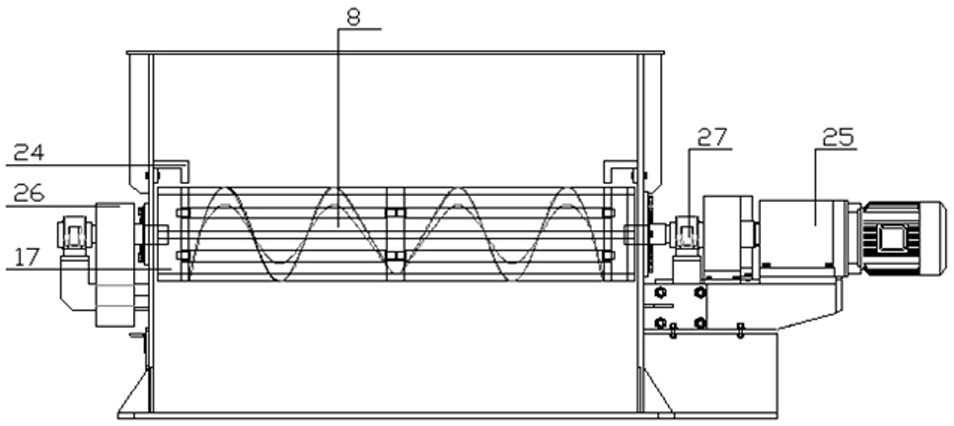

Stirring device for water conservancy and hydropower engineering construction and using method

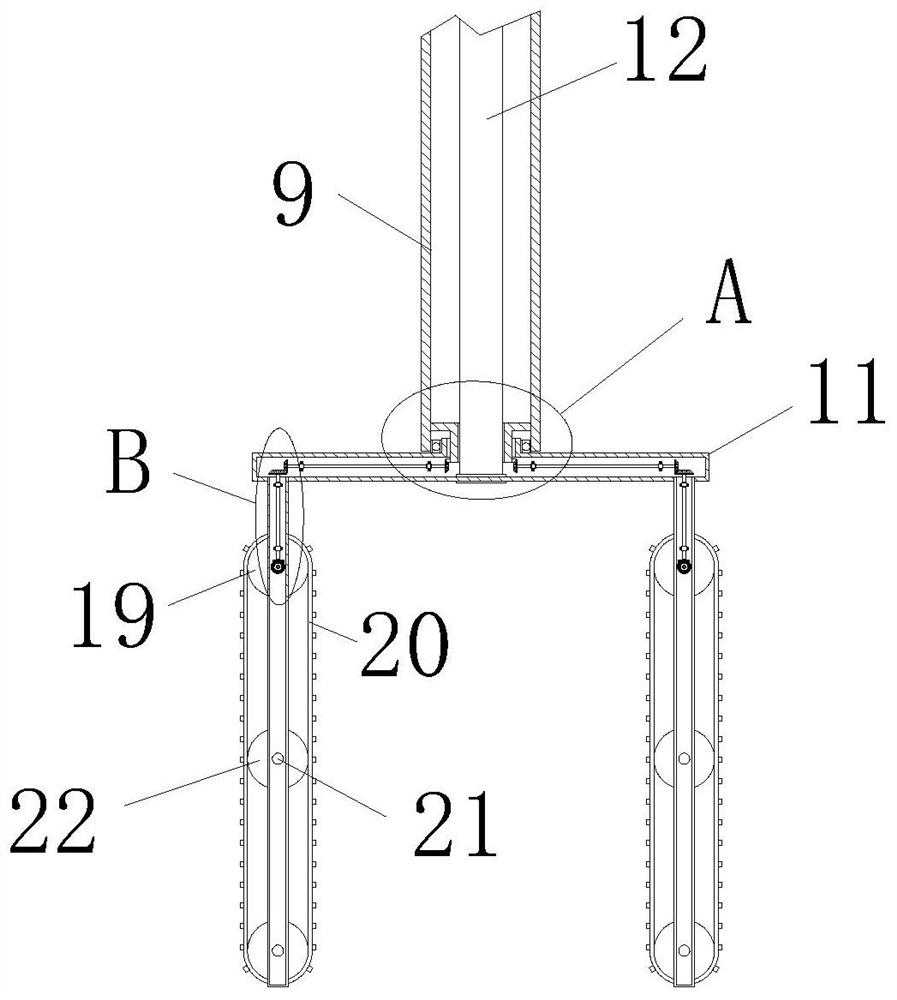

PendingCN113910449ASolve the uniformity problemSolve uneven compositionCement mixing apparatusHydropower engineeringStructural engineering

The invention relates to the technical field of constructional engineering equipment, in particular to a stirring device for water conservancy and hydropower engineering construction and a using method. The stirring device comprises two supports, a horizontal rod is rotationally connected between the top ends of the two supports, a cavity is formed in the center position of the horizontal rod, angle adjusting rotating shafts are rotationally connected in the front portion and the rear portion of the cavity correspondingly, a position adjusting cylinder is fixedly connected between the two angle adjusting rotating shafts, the surface of one angle adjusting rotating shaft is connected with a worm gear in a sleeved manner, the worm gear is in transmission connection with an angle adjusting mechanism, and a stirring mechanism is fixedly installed on the inner wall of the angle adjusting rotating shaft. When concrete is stirred, stirring in the horizontal direction and the vertical direction can be carried out at the same time, the uniformity problem of the concrete in the horizontal direction is solved, and meanwhile the problem that components of the concrete are not uniform due to the gravity influence in the vertical direction is solved.

Owner:安徽福苗建设有限公司

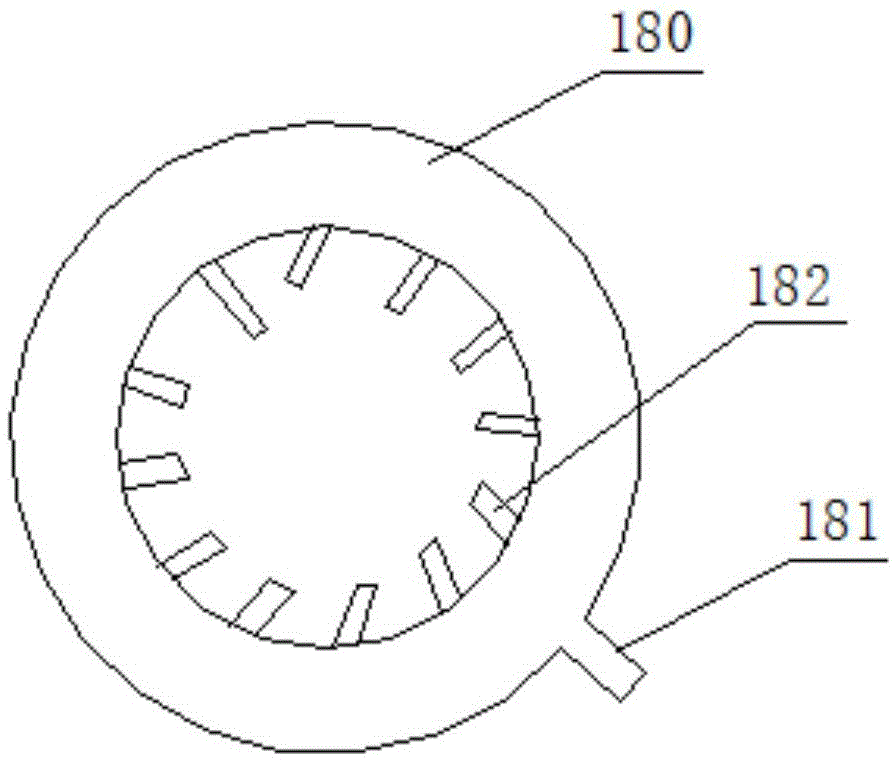

Particle cutting mechanism for biomass particle pelletizer

InactiveCN104399407ASolve the uniformity problemSimple structureBiofuelsSolid fuelsBarrel ShapedInverted t

A particle cutting mechanism for a biomass particle pelletizer comprises a cover, a scraper and a scraper driving device, wherein a first through hole is formed at the bottom of the barrel-shaped cover; the internal diameter of an open end of the barrel-shaped cover is greater than the external diameter of a ring mold of the biomass particle pelletizer; the scraper driving device comprises a motor, a bull gear and a plurality of bull gear connecting rods; the bull gear connecting rods are connected to the bottom of the barrel-shaped cover; a T-shaped roll shaft is connected with the tail end of each connecting rod; a second through hole is formed in the center of the bull gear; the diameter of the second through hole is not less than that of the first through hole; an annular groove with an inverted T-shaped cross section is formed on one side of the gear; the T-shaped roll shafts are embedded into the annular groove and connected with the annular groove in a sliding manner; the scraper is connected onto the other side of the bull gear and rotates between an external wall of the ring mold of the biomass particle pelletizer and an internal wall of the barrel-shaped cover with the bull gear; a track of a cutting edge of the scraper is annular; and the annular track corresponds to a position of the external wall of the ring mold of the biomass particle pelletizer.

Owner:CHANGZHOU FARTHEST MACHINERY

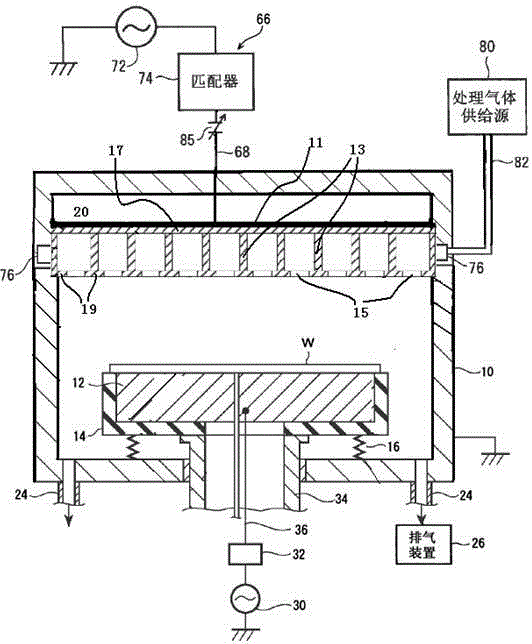

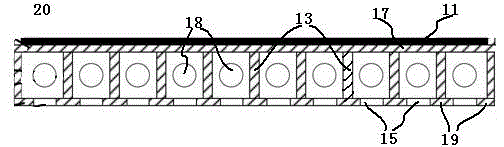

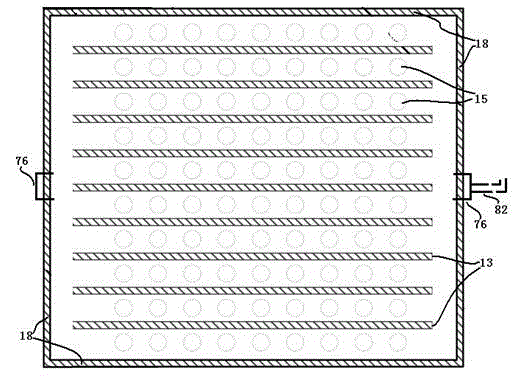

Capacitance coupling type plasma processing apparatus

InactiveCN104918399AModulation Precise ControlFine control density distributionPlasma techniquePlasma jetCapacitance

The invention, which belongs to the technical field of plasma processing, discloses a capacitance coupling type plasma processing apparatus. According to the invention, a plasma jet discharge array arranged at the top of a processing cavity contains a high-voltage electrode, a barrier medium flat plate, and a work air-flow channel layer. The barrier medium flat plate includes a meta-material base material layer and metal wire structure units attached to the meta-material substrate layer. Under the circumstances that the base material is selected and determined, a needed modulation effect can be obtained by changing the patterns and designed dimensions of the metal wire structure units and / or arrangement of the metal wire structure units in space, thereby changing electromagnetic parameters epsilon and mu of each unit in the space where the meta-material is located. An equivalent electromagnetic parameter of each point in the space is designed and the equivalent capacitance is also obtained correspondingly, thereby obtaining a response frequency of each metal wire structure unit and thus precisely controlling modulation of each point in the space where the meta-material is located. Therefore, diversified precise controlling of the plasma density distribution is realized.

Owner:山东专利工程总公司

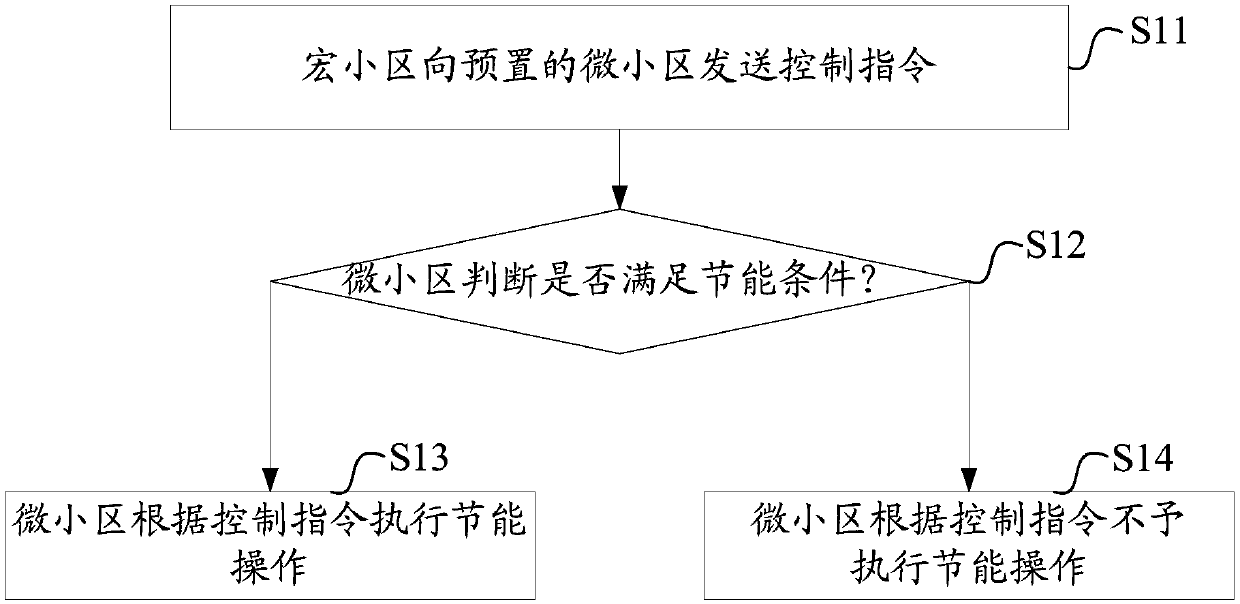

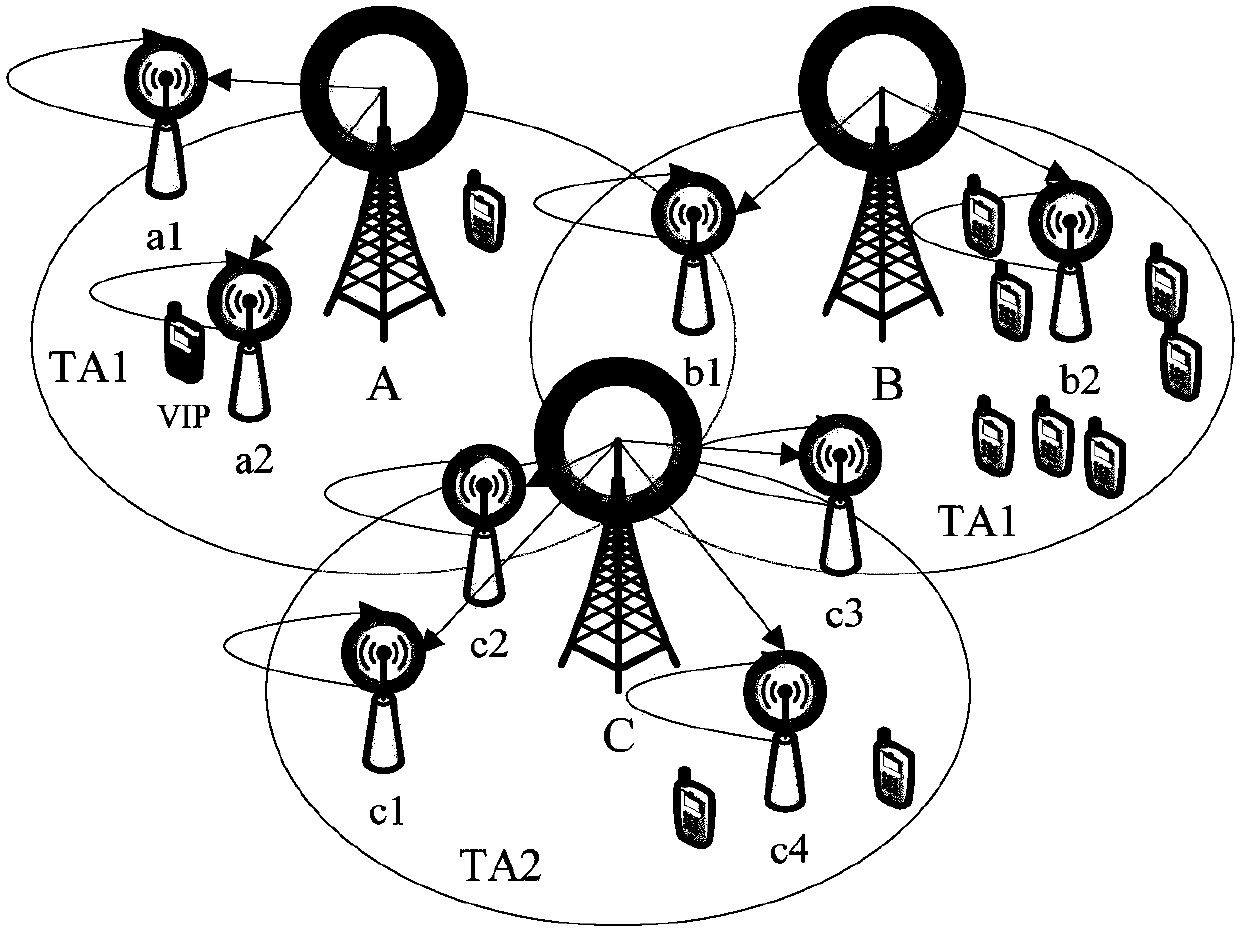

Energy-saving control method and system for heterogeneous network

InactiveCN107787008ARealize unified deploymentEasy to controlPower managementNetwork traffic/resource managementMicro cellHeterogeneous network

The invention discloses an energy-saving control method and system for a heterogeneous network, and belongs to the technical field of communication. The method includes the following steps: a macro cell sends a control instruction to a preset micro cell; the micro cell judges whether an energy-saving condition is met, and when the energy-saving condition is met, an energy-saving operation is performed according to the control instruction; and when the energy-saving condition is not met, the energy-saving operation is not performed according to the control instruction. Therefore, through the independent operation of the macro cell and the micro cell, the normal operation of the cooperative work of the macro cell and the micro cell can be ensured, the phenomenon that the macro cell and the micro cell do not interfere with each other can also be ensured, the unified deployment and control of the energy-saving operation can be implemented, and thus each micro cell can orderly enter or exitan energy-saving state according to the own actual situation; and the coordination and flexibility of the system can be improved, an energy-saving control process can be more orderly and efficient, an energy-saving function can be applied more reasonably and flexibly on the basis of ensuring the user experience, and the conflicts and balance between energy saving and performance and between energy saving and services can be solved.

Owner:ZTE CORP

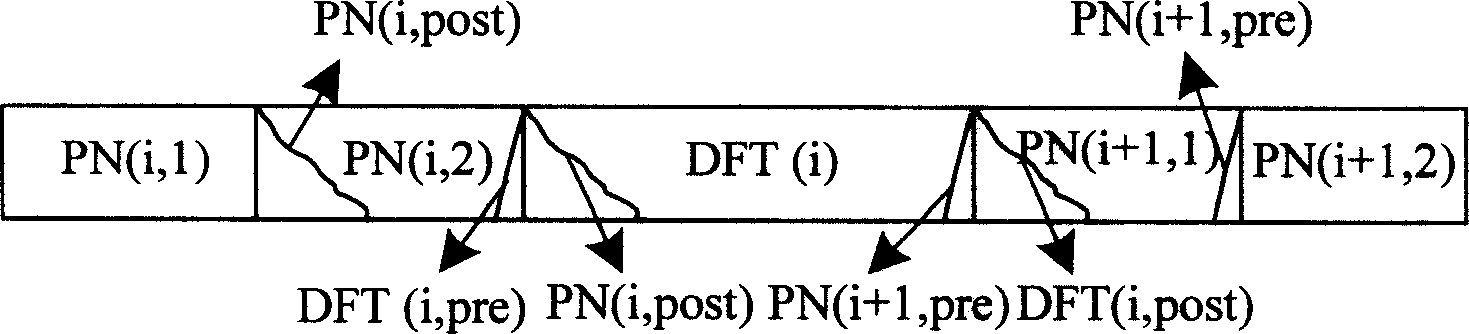

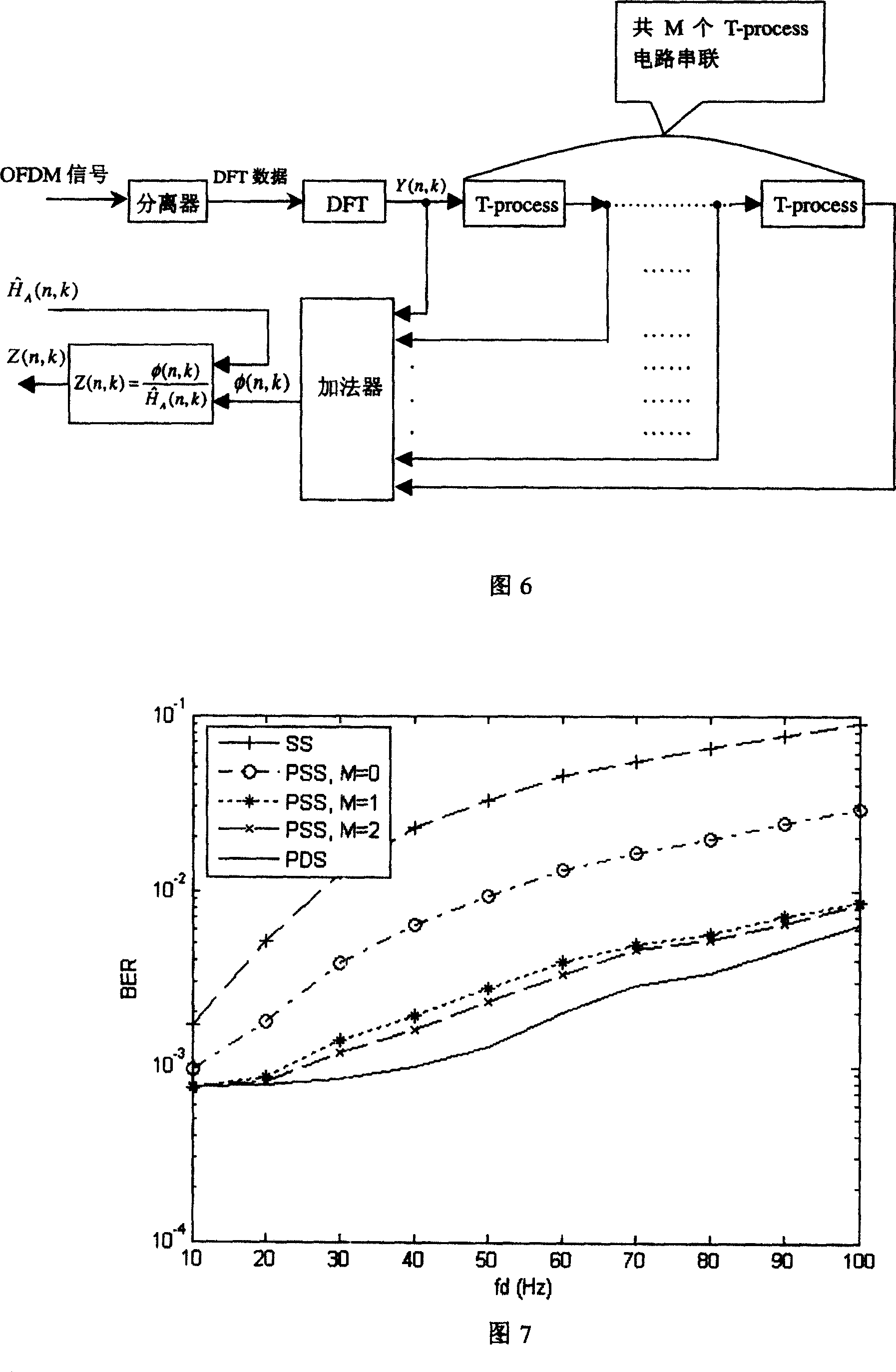

tds‑ofdm channel estimation and equalization method and system

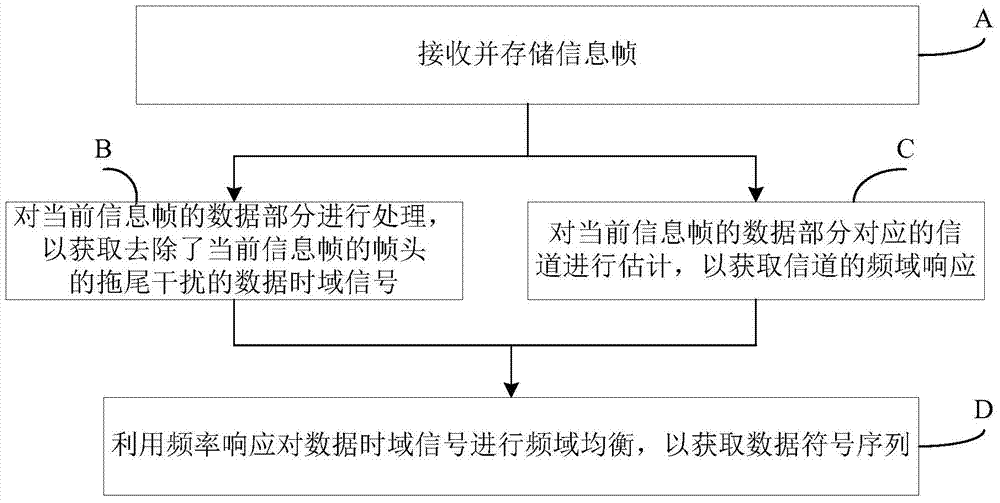

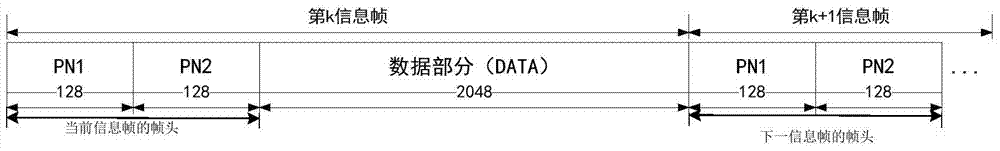

ActiveCN104394105BImprove accuracySimple structureBaseband system detailsMulti-frequency code systemsTime domainUltra high speed

The invention provides a TDS-OFDM (Time Domain Synchronous-Orthogonal Frequency Division Multiplexing) channel estimation equalization method. The TDS-OFDM channel estimation equalization method comprises receiving and storing information frames and extracting a frame header and the data portion of the current information frame and a frame header of the next information frame; processing the data portion of the current information frame so as to obtain data time domain signals, wherein the trailing interference of the frame header of the current information frame in the data time domain signals is eliminated; performing estimation on a channel which is corresponding to the data portion of the current information frame so as to obtain the frequency domain response of the channel; performing the frequency domain equalization on the time domain signals through the frequency domain response so as to obtain a data symbol sequence. The TDS-OFDM channel estimation equalization method can be applied to the large doppler range and a rapid time-varying channel and is suitable for ultra-high-speed mobile application scenarios. The invention also provides a TDS-OFDM channel estimation equalization system.

Owner:TSINGHUA UNIV +1

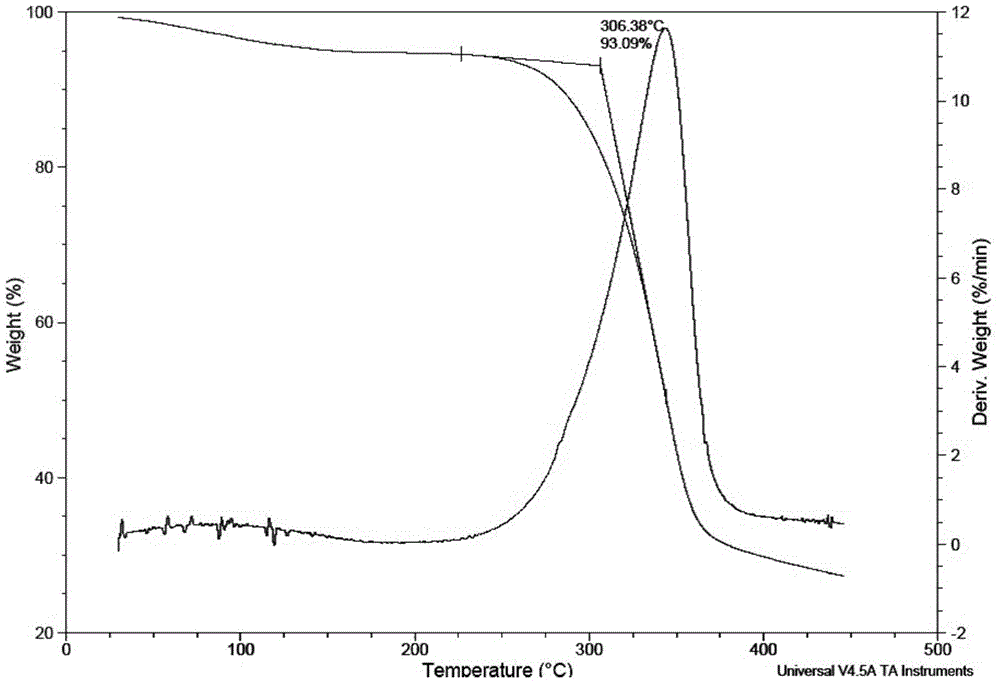

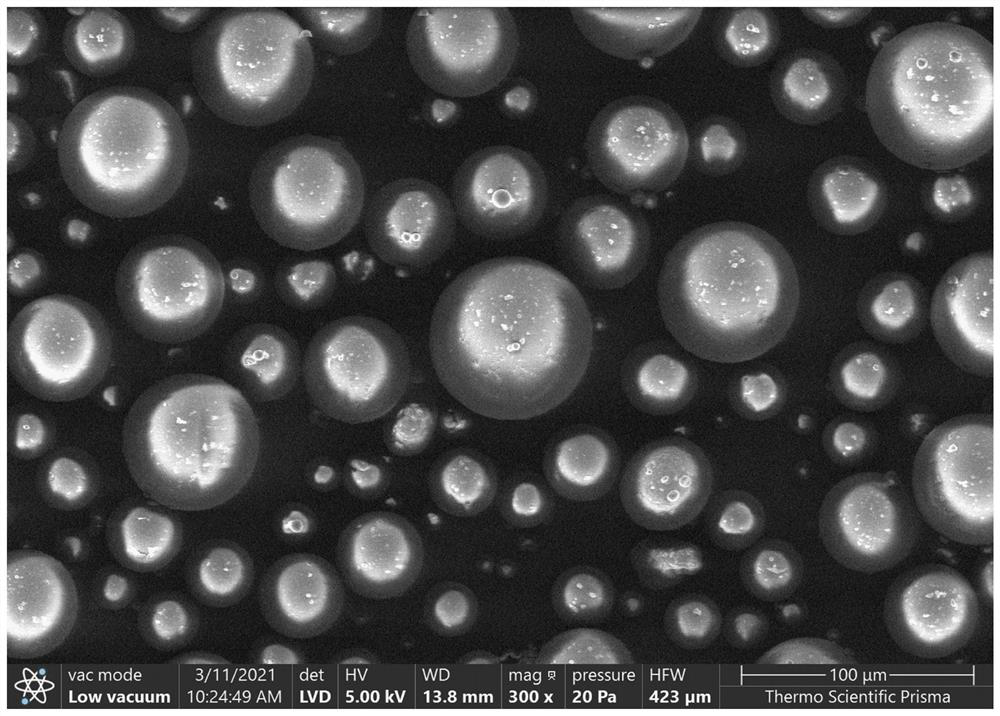

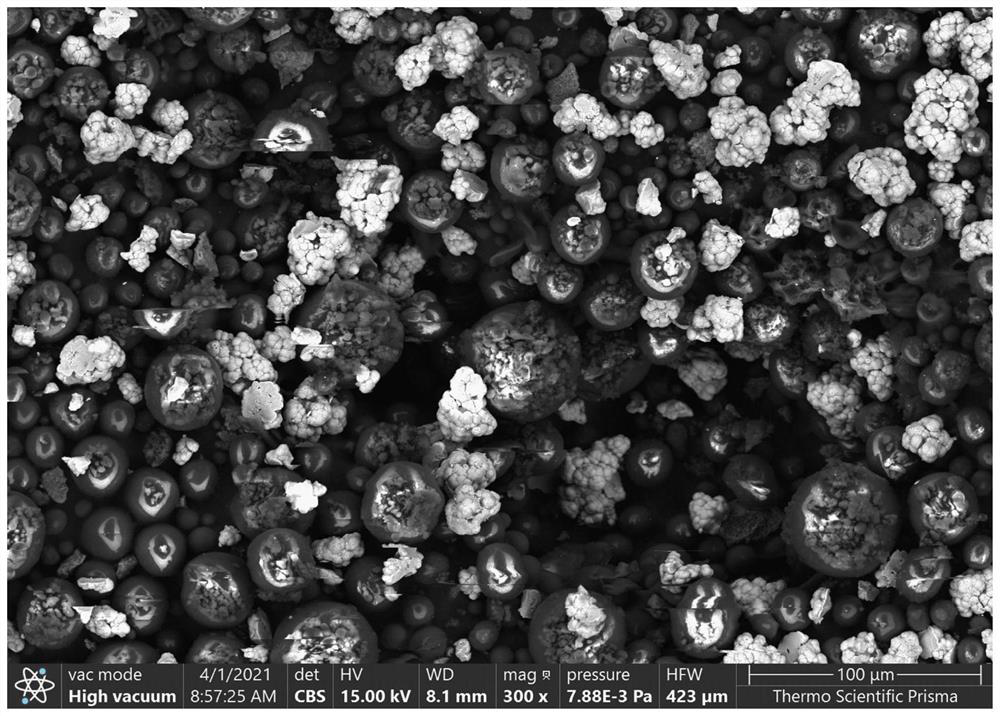

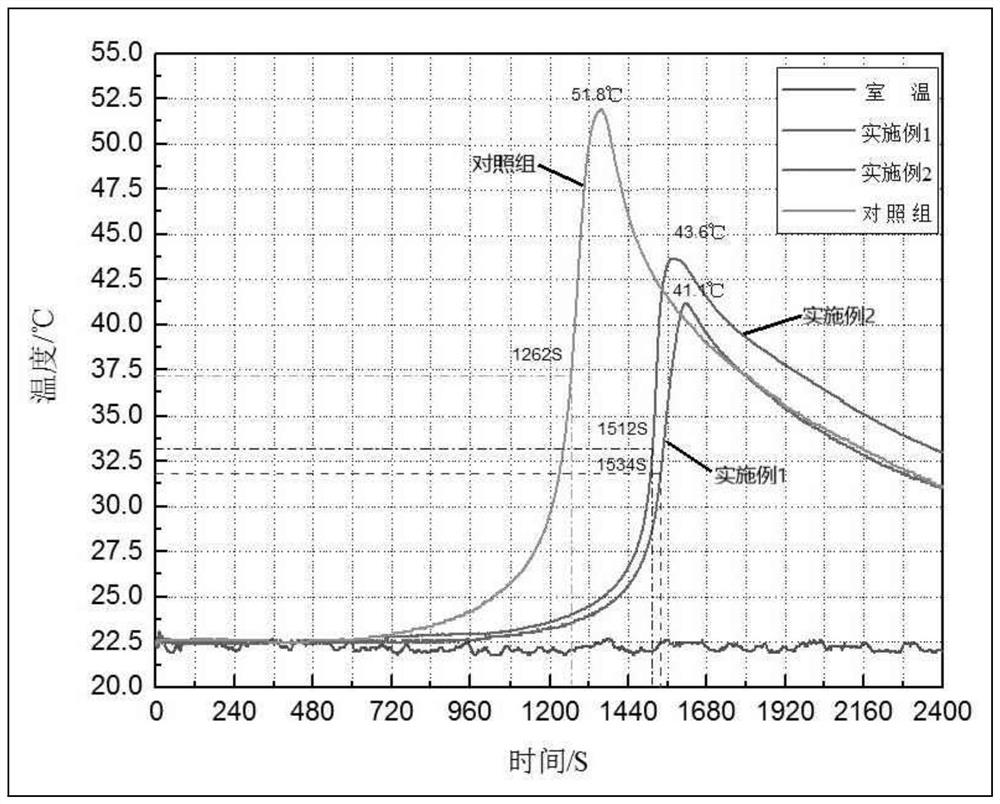

Methyl methacrylate copolymer microsphere encapsulated with initiator, preparation method and injectable bone cement

PendingCN114561030ASolve the uniformity problemImprove heat damagePharmaceutical delivery mechanismTissue regenerationPolymer scienceInjectable bone

The invention relates to an initiator-encapsulated methyl methacrylate copolymer microsphere, a preparation method and injectable bone cement. When the initiator-encapsulated methyl methacrylate copolymer microsphere is applied to injectable bone cement, the initiator-encapsulated methyl methacrylate copolymer microsphere is gradually wetted and dissolved by a monomer, the initial viscosity of bone cement slurry is gradually changed in the dissolving process, the degree of polymerization reaction is relatively gentle, and the injectable bone cement is more stable. And the heat release temperature is obviously reduced, so that the operation time in the clinical use process can be effectively prolonged, and the heat injury to tissues can be improved.

Owner:DABO MEDICAL TECH CO LTD

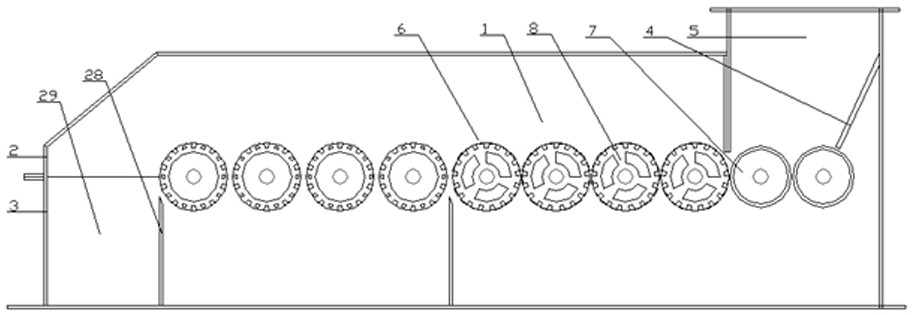

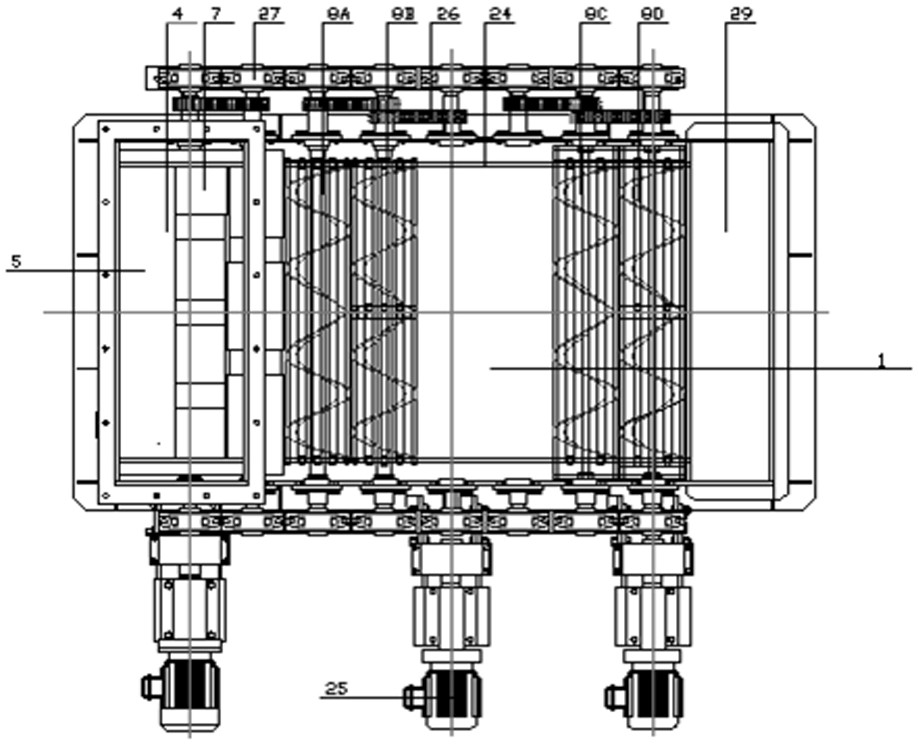

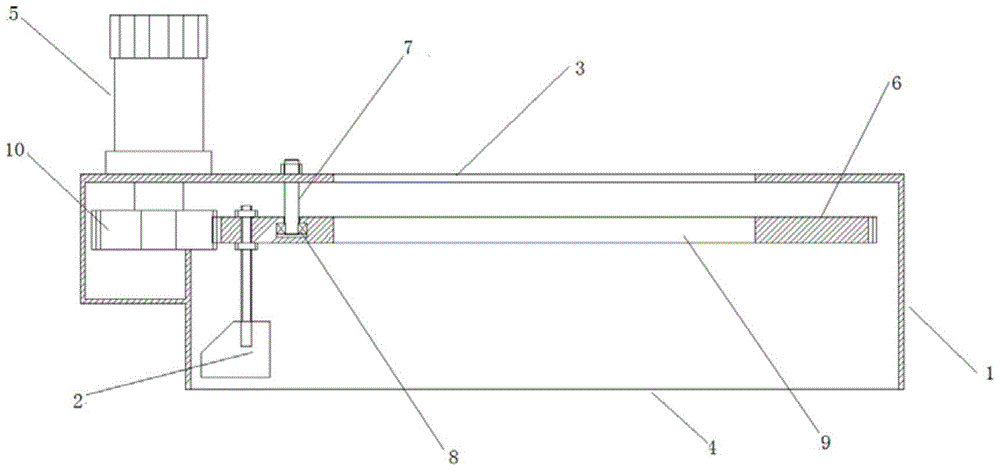

Screening distributor based on trapezoidal screen bar screen shaft

PendingCN112871622ASolve the uniformity problemSolve noise pollutionSievingScreeningStructural engineeringBar screen

The invention discloses a screening distributor based on a trapezoidal screen bar screen shaft. The trapezoidal screen bar screen shaft (8) comprises positioning flanges and a plurality of trapezoidal movable screen bars (10), wherein the trapezoidal movable screen bars (10) are arranged between the positioning flanges in a penetrating mode, trapezoidal ends (11) are arranged at the two ends of the trapezoidal movable screen bars (10), and the trapezoidal ends (11) are opposite to the upper bottoms and the lower bottoms of the trapezoidal movable screen bars (10); a plurality of trapezoidal movable holes (12) matched with the trapezoidal ends (11) are formed in the positioning flanges, the section size of the trapezoidal ends (11) is smaller than that of the trapezoidal movable holes (12), and the upper bottoms and the lower bottoms of the trapezoidal movable screen bars (10) are consistent in direction; and in the overall rolling process of the trapezoidal screen bar screen shaft (8), the trapezoidal ends (11) swing up and down and left and right in the trapezoidal movable holes (12), so that movable screen seams (16) are formed. According to the screening distributor, fine-grained materials can be efficiently screened without blocking the screen seams.

Owner:SICHUAN ZHONGMENG ELECTRIC POWER EQUIP MFG CO LTD

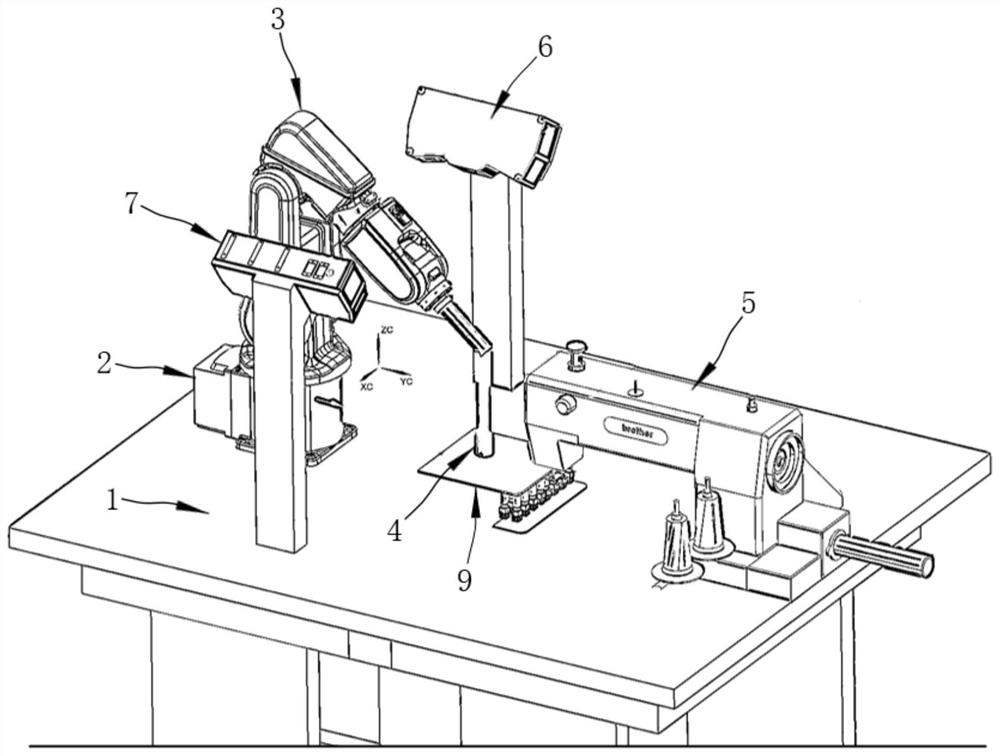

Intelligent 3D visual identification sewing machine and application method thereof

ActiveCN114808281AFlexible replacementSolve the uniformity problemProgramme-controlled sewing machinesManufacturing computing systemsControl engineeringVisual recognition

The embodiment of the invention discloses an intelligent 3D visual recognition sewing machine and an application method thereof, and the sewing machine comprises a workbench which is provided with a sewing position; the multi-degree-of-freedom driving structure comprises a displacement driving table and a degree-of-freedom mechanical arm which are in transmission connection; the driving head is in transmission assembly connection with the degree-of-freedom mechanical arm, the driving head corresponds to the sewing position, and the driving head is provided with a feeding and discharging end and a suction pressure transmission end; a sewing machine head of the sewing assembly corresponds to the sewing position; the visual detection range of the 3D visual sensor is from the motion range of the feeding and discharging end to the sewing position; the control input end of the master console is connected with the 3D visual sensor through a circuit, and the control output end of the master console is connected with the multi-degree-of-freedom driving structure, the driving head and the sewing assembly through circuits. The technical problems that due to the fact that an existing sewing machine still needs manual operation, the labor cost consumption is high, the working efficiency is low, the overall productivity is not high, and the product yield is low are solved.

Owner:易麦斯智能科技(无锡)有限公司

Pellet cutting mechanism for biomass pellet granulator

InactiveCN104399407BSolve the uniformity problemSimple structureBiofuelsSolid fuelsParticulatesInverted t

A particle cutting mechanism for a biomass particle pelletizer comprises a cover, a scraper and a scraper driving device, wherein a first through hole is formed at the bottom of the barrel-shaped cover; the internal diameter of an open end of the barrel-shaped cover is greater than the external diameter of a ring mold of the biomass particle pelletizer; the scraper driving device comprises a motor, a bull gear and a plurality of bull gear connecting rods; the bull gear connecting rods are connected to the bottom of the barrel-shaped cover; a T-shaped roll shaft is connected with the tail end of each connecting rod; a second through hole is formed in the center of the bull gear; the diameter of the second through hole is not less than that of the first through hole; an annular groove with an inverted T-shaped cross section is formed on one side of the gear; the T-shaped roll shafts are embedded into the annular groove and connected with the annular groove in a sliding manner; the scraper is connected onto the other side of the bull gear and rotates between an external wall of the ring mold of the biomass particle pelletizer and an internal wall of the barrel-shaped cover with the bull gear; a track of a cutting edge of the scraper is annular; and the annular track corresponds to a position of the external wall of the ring mold of the biomass particle pelletizer.

Owner:CHANGZHOU FARTHEST MACHINERY

A dynamic and static hybrid coating system and a method for performing dynamic and static hybrid coating using the same

ActiveCN103993273BSolve electrostatic damageSolve the uniformity problemVacuum evaporation coatingSputtering coatingComing outCoating system

The invention relates to a coating system and a coating method, especially to a dynamic / static hybrid coating system and a dynamic / static hybrid coating method by the utilization of the dynamic / static hybrid coating system. The dynamic / static hybrid coating system comprises a static coating system and a dynamic coating system. The static coating system contains a static coating chamber, a first coating assembly and a first transmission assembly. The reciprocating scan distance is zero or any distance less than the spacing between adjacent target materials. The dynamic coating system contains a dynamic coating chamber, a second coating assembly and a second transmission assembly. The dynamic / static hybrid coating method contains two modes. The first mode is as follows: static coating comes first and dynamic coating follows; then vertical transition of a substrate is conducted and the substrate comes out in a reverse direction; and the substrate is uncoated after translation. The second mode is as follows: the substrate firstly enters the innermost chamber; static coating is conducted after vertical transition; then, the substrate comes out in a reverse direction for dynamic coating; and finally, the substrate comes out from a low vacuum chamber. By the system and the method, a substrate can be coated and coating is uniform. Electrostatic damage to an electrostatic sensitive device can be prevented.

Owner:ZHEJIANG SHANGFANG ELECTRONICS EQUIP

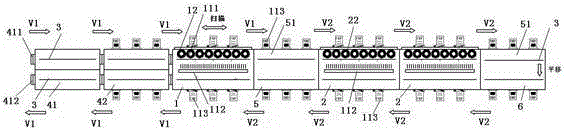

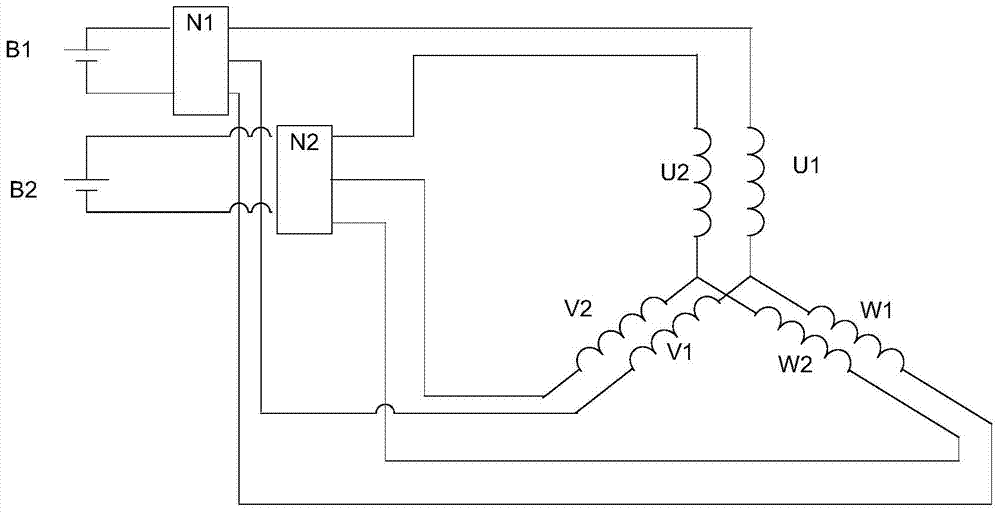

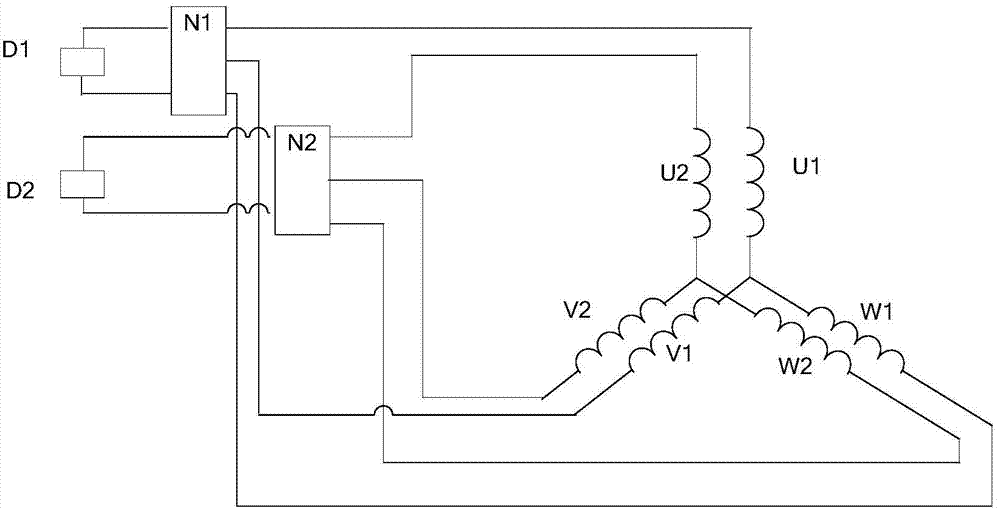

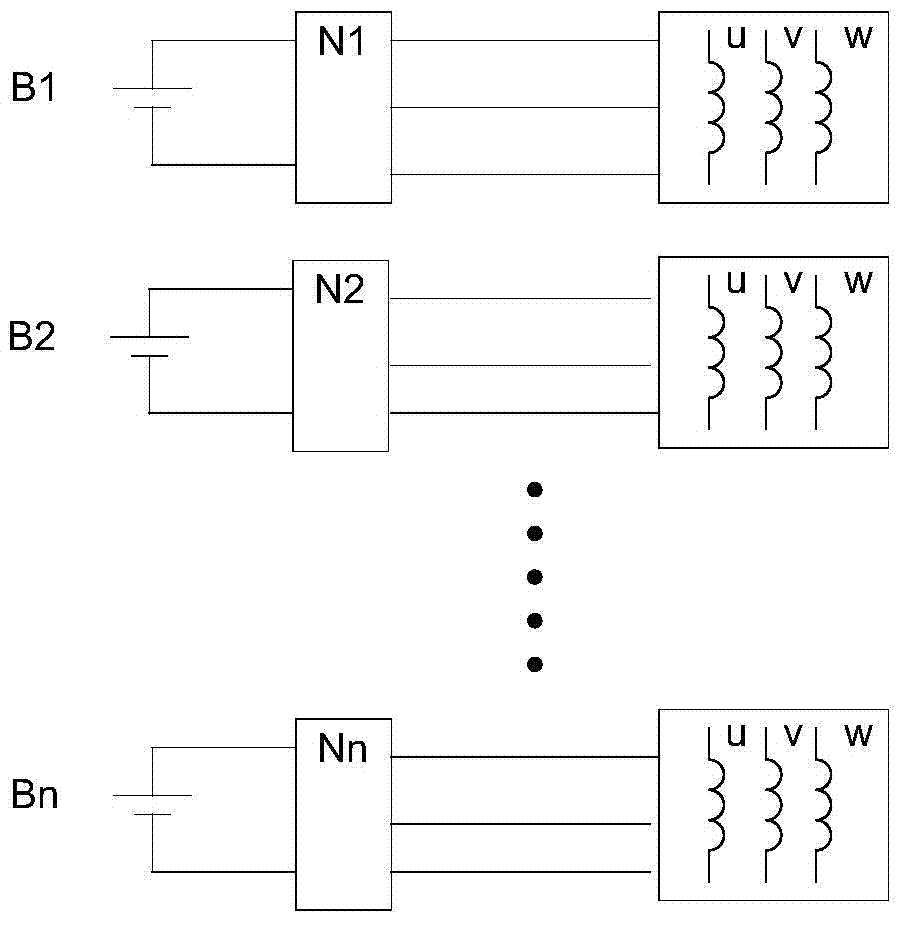

Electric vehicle, power system and control method of electric vehicle

ActiveCN104260642ASolve the uniformity problemSolve the problem of high voltageElectric devicesVehicular energy storageElectrical batteryElectric machine

The invention relates to an electric vehicle, a power system and a control method of the electric vehicle. The power system of the electric vehicle comprises at least one driving motor; a stator winding of the driving motor is divided into at least two sets of mutually-insulated winding branches; a corresponding power supply system supplies power to each set of winding branches, wherein each power supply system comprises a corresponding cell unit and an inverter; all cell units are independent from each other. According to the electric vehicle, the power system and the control method of the electric vehicle, the power supply system is characterized in that the stator winding of the driving motor is composed of the plurality of sets of winding branches, each winding branch can independently gain power from the corresponding cell unit, and therefore, all cell units do to need electrical connection, and as a result, the problems of balancing between large serially-connected and parallel-connected cell packs, and high voltage can be completely solved.

Owner:庄森

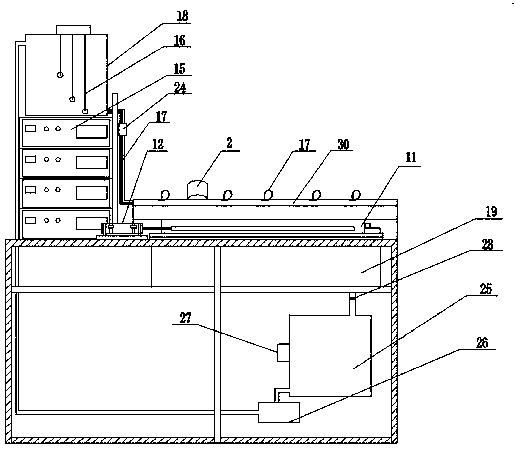

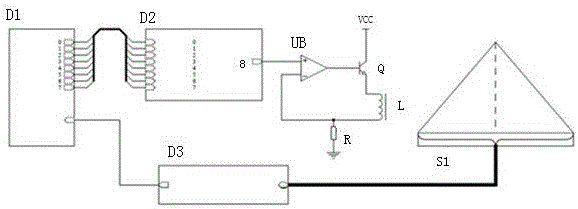

Ultrasonic emulsification feeding device and feeding method for cigarettes

ActiveCN103082391BSolve the uniformity problemAchieve uniformityTobacco preparationUltrasonic emulsificationGranularity

Owner:HUBEI CHINA TOBACCO IND

Self-correcting electron beam scanning output system

ActiveCN103279060BGuaranteed to be relatively constantSolve the uniformity problemProgramme controlComputer controlNegative feedbackMicrocontroller

The invention relates to a self-correction electron beam scanning output system, which comprises a single chip system, a D / A (digital / analog) conversion unit, an amplification circuit unit, a power amplification unit, a dose sensor unit and a dose signal processing unit. The self-correction electron beam scanning output system can overcome the defect of the prior art that the scanning degree is non-uniform, a negative feedback mechanism under the large-power amplification circuit and a real-time monitoring and feedback mechanism of the scanning dose are adopted, the correction is carried out according to the real dose and the set dose, so that the irradiation dose on each part of a cargo in scanning is in consistency.

Owner:SHANDONG LANFU HIGH ENERGY PHYSICS TECH CO LTD

Time-varying channel evaluation and equalizing method and system for TDS-OFDM receiver

InactiveCN100376103CSolve the uniformity problemImprove robustnessMulti-frequency code systemsCarrier signalInformation transfer

Owner:TSINGHUA UNIV

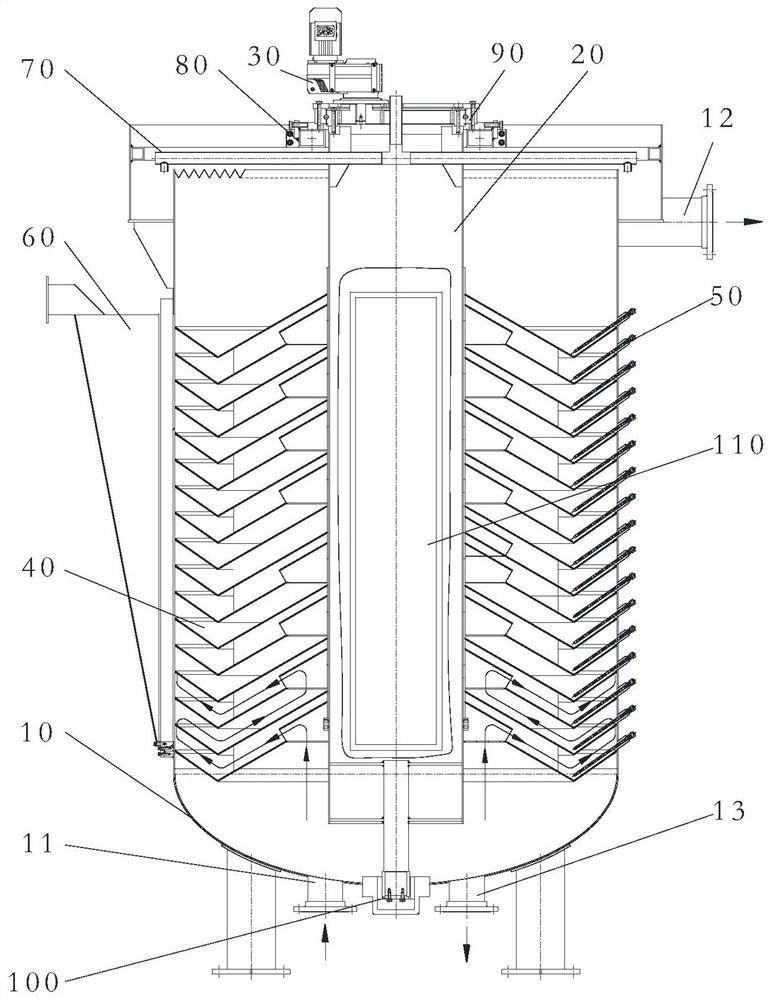

Catalytic reaction device

PendingCN112811569ASolve the uniformity problemIncrease contact areaWater/sewage treatment apparatusWater/sewage treatment by oxidationPhysicsEngineering

The invention provides a catalytic reaction device which comprises a tank body, a rotating shaft, a driving part and flow guide discs; a liquid inlet is formed in the bottom of the tank body, and a liquid outlet is formed in the top of the tank body; the rotating shaft is longitudinally arranged in the tank body in a penetrating manner; the driving part is in driving connection with the rotating shaft and drives the rotating shaft to rotate; the flow guide discs are arranged on the outer side of the rotating shaft in a sleeving mode, rotate synchronously with the rotating shaft, are arranged in the axial direction of the rotating shaft and comprise upper discs and lower discs, the upper discs and the lower discs are used for containing catalysts and are longitudinally arranged at intervals, and channels for liquid to pass through are formed in the inner sides, close to the rotating shaft, of the lower discs and the outer sides, away from the rotating shaft, of the upper discs; and liquid introduced into the tank body from the liquid inlet flows between the upper disc and the lower disc and among the flow guide discs in an S shape. The problems of non-uniform and insufficient reaction of a water treatment device in the prior art are solved.

Owner:北京启元汇通水务科技股份有限公司

A 3D printer stability control method and control system

ActiveCN105643944BImprove stabilitySolve the uniformity problemAdditive manufacturing apparatusManufacturing data aquisition/processingUltrasound attenuationControl system

An embodiment of the invention provides a 3D printer stability control method and a control system and relates to the technical field of three-dimensional printing. The 3D printer stability control method comprises: acquiring a comprehensive control valve of a first 3D printer module for a second 3D printer module, acquiring an iterative control module of the 3D printer to obtain a relation between an iterative control function and a threshold error value during ith (I being a positive integer greater than 0) control, further acquiring an optimal threshold error value function, and solving an optimal threshold error value. In the 3D printer stability control method and the control system of the invention, by constructing the optimal threshold error value model and by selecting the optimal threshold error value in real time through an attenuation integral balance point of recommended control valves, it is possible to well solve the problem that recommended control valves of a forming process of a 3D printer experience a balance and imbalance attenuation along with changes in a threshold value and to improve the stability of the printer.

Owner:三维泰柯(厦门)电子科技有限公司

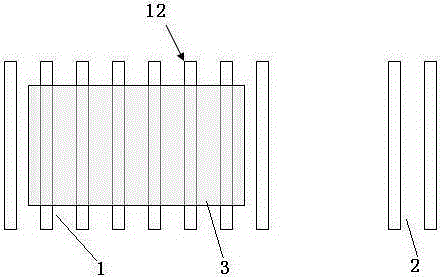

Co-extrusion molding optical film equipment

ActiveCN114800997APrevent leakageSolve the uniformity problemOptical articlesCo extrusionMechanical engineering

The invention discloses co-extrusion forming optical film equipment which comprises a sliding table and a co-extrusion device, a forming table is slidably connected to the sliding table, a forming groove is formed in the forming table, the inner bottom of the forming groove is a smooth plane, the co-extrusion device can output finished product materials into the forming groove, a second portal frame is fixed to the sliding table, and a second portal frame is fixed to the second portal frame. A first air cylinder is fixedly installed on the second portal frame, the output end of the first air cylinder is fixedly connected with a first forming module, the bottom of the first forming module is equal to the inner bottom of the forming groove, and the first forming module moves downwards and can enter and seal the forming groove; according to the extrusion forming device, the co-extruded optical film material can be subjected to extrusion forming in the forming groove, and after the optical film is formed, a boundary protection coating and a protection surface layer can be formed on the upper surface of the optical film.

Owner:NANJING BREADY ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com