A dynamic and static hybrid coating system and a method for performing dynamic and static hybrid coating using the same

A hybrid coating and coating system technology, applied in the direction of sputtering coating, ion implantation coating, vacuum evaporation coating, etc., can solve the problems of voltage difference, electrostatic damage, glass substrate coating failure, etc., to improve the uniformity of the film, Solve the problem of uniformity and avoid the effect of electrostatic damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

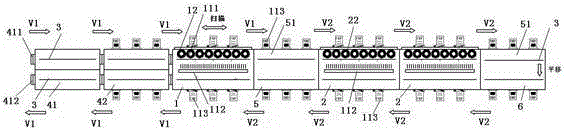

[0066] For the coating method of the first mode, see image 3 ,specifically is:

[0067] 1) Place the substrate 3 on the substrate carrier, pass through the low-vacuum switching chamber 41 and the high-vacuum switching chamber 42 in turn at the first conveying speed of 25m / min, and then enter the static coating chamber at the first conveying speed V1 of 25m / min 1. Make the surface to be coated of the substrate 3 face the first coating assembly 12 in the static coating chamber 1, and make the substrate 3 perform pure static coating or reciprocating scanning coating in the static coating chamber 1;

[0068] 2) The static coated substrate 3 enters the first buffer chamber 5 at a constant speed at a first transmission speed of 25 m / min, and then enters the dynamic coating chamber 2 at a second transmission speed V2 of 4 m / min for continuous dynamic transmission coating;

[0069] 3) Make the dynamically coated substrate 3 enter the second buffer chamber 6 at the second transmissio...

Embodiment 2

[0071] The coating method of the first mode is the same as the first embodiment, except that the first transmission speed V1 is 1 m / min; the second transmission speed V2 is 0.5 m / min.

Embodiment 3

[0073] The coating method of the first mode is the same as the first embodiment, except that the first transmission speed V1 is 30 m / min; the second transmission speed V2 is 10 m / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com