Capacitance coupling type plasma processing apparatus

A plasma and processing device technology, applied in the field of plasma processing, can solve the problems of plasma shape change, instability, destruction of plasma confinement or limit confinement time, etc., to achieve the effect of increasing stability and solving uniformity problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

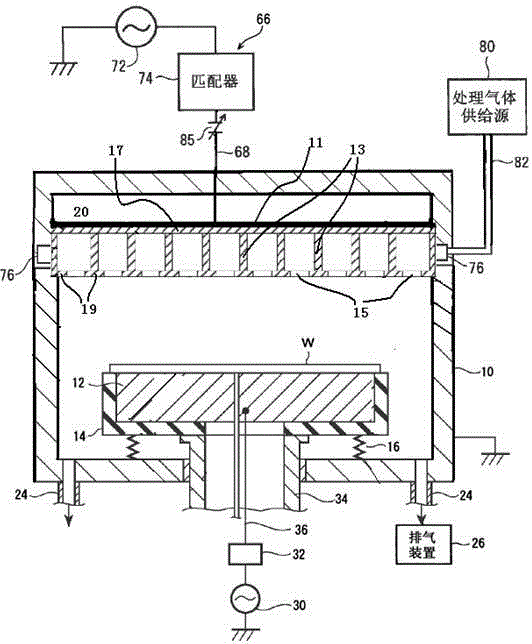

[0031] Such as figure 1 , figure 2 , image 3 As shown, the capacitively coupled plasma processing apparatus according to one embodiment of the present invention is a plasma apparatus using a high-voltage electrode. There is a vacuum processing chamber 10 made of metal such as aluminum or stainless steel, and the processing chamber 10 is safely grounded.

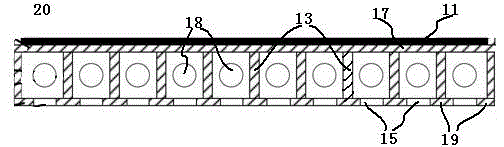

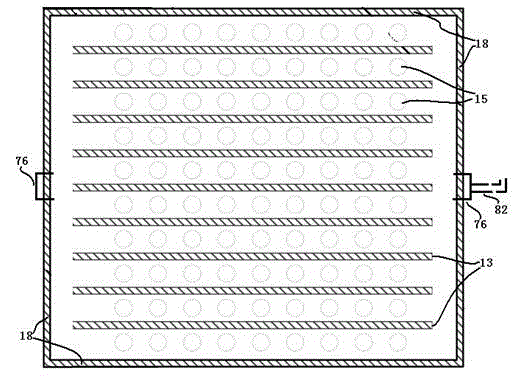

[0032] A plasma jet discharge unit is airtightly installed on the top of the processing chamber 10 . The plasma jet discharge unit is a plasma jet discharge array 20 . The plasma jet discharge array 20 includes a three-layer planar layer structure, which is a high-voltage electrode 11, a blocking dielectric plate 17, and a working air flow channel layer in sequence from top to bottom. Below the processing chamber 10 and opposite to the plasma jet discharge array 20, there is a mounting table 12 for mounting the substrate to be processed. The mounting table 12 is made of a conductive material (such as anodized aluminum) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com