Inductive coupling type plasma processing apparatus

A plasma and processing device technology, applied in the field of plasma processing, can solve the problems of plasma shape change, instability, plasma velocity spatial distribution function deviation, etc., to improve controllability, increase stability, and solve uniformity problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

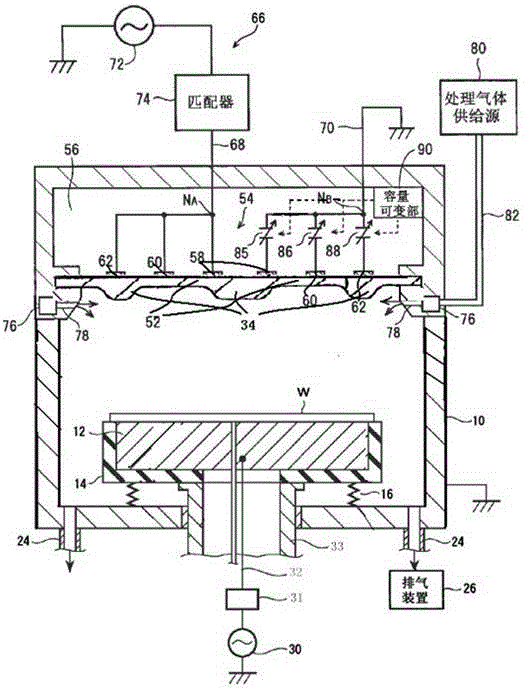

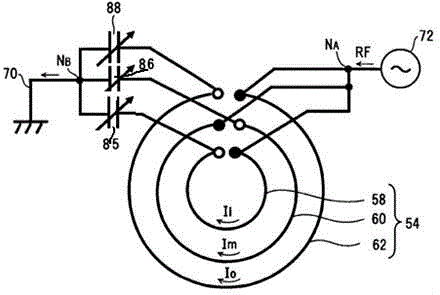

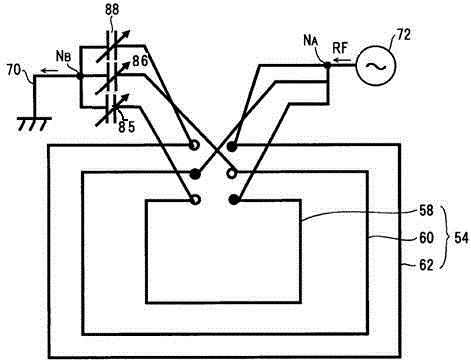

[0038] like figure 1 As shown, an inductively coupled plasma processing device according to an embodiment of the present invention is an inductively coupled plasma device using a planar coil radio frequency antenna, and includes a vacuum processing chamber 10 made of metal such as aluminum or stainless steel. 10 is safely grounded.

[0039] The top of the processing chamber 10 is airtightly installed with a metamaterial top plate 52 made of metamaterial. The processing chamber 10 is provided with a mounting table 12 made of conductive material (such as aluminum with anodized surface) for mounting the substrate to be processed, and the mounting table 12 doubles as a high-frequency electrode; The substrate W on the stage 12 is attracted and held by the electrostatic chuck. The mounting platform 12 is accommodated in the insulating frame 14, and the insulating frame 14 is supported by a hollow pillar 33; the bottom end of the pillar 33 is located outside the processing chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com