Automatic brushing and plating machine

A semi-automatic, brush-plating technology, applied in the direction of electrodes, electrolytic processes, electrolytic components, etc., can solve problems such as difficult to guarantee brush-plating quality, low brush-plating production efficiency, poor product consistency, etc., to ensure quality, solve coating uniformity, good electrical contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

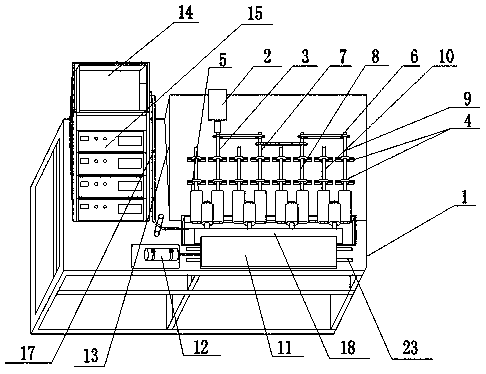

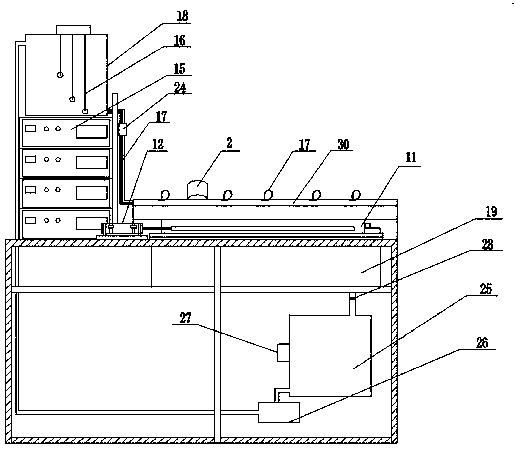

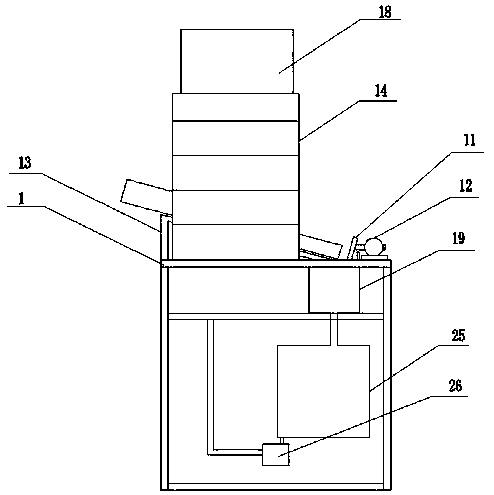

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

[0029] Embodiment of the present invention: a semi-automatic brush plating machine, including a table body 1, a roller table 13 is arranged on the table body 1, a variable speed motor 2 is arranged on the roller table 13, and the power output end of the variable speed motor 2 is connected to the first active bearing The rod 3, the first active bearing rod 3 passes through the bearing seat 4 to connect the roller 5, and there is an oblique angle of 15-20° between the roller table 13 and the plane of the table body 1.

[0030] The first active bearing rod 3 is connected to the second active bearing rod 7 through the chain 6, the second active bearing rod 7 is connected to the third active bearing rod 8 through the chain 6, and the third active bearing rod 8 is connected to the fourth active bearing rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com