Pellet cutting mechanism for biomass pellet granulator

A technology of biomass pellets and cutting mechanism, which is applied in the directions of biofuel, raw material extrusion pelletization, die extrusion pelletization, etc., can solve the problems of uneven particle size and uneven combustion degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

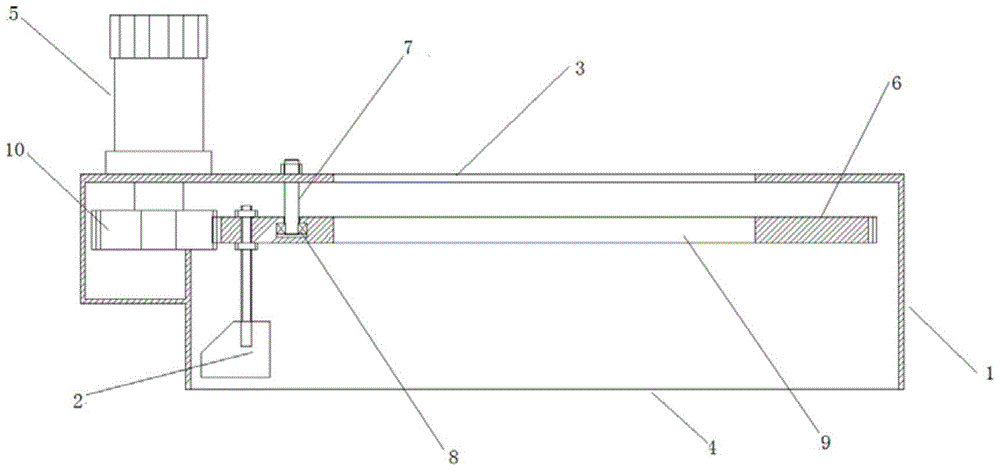

[0012] Below in conjunction with accompanying drawing and specific embodiment the technical scheme is further described as follows:

[0013] Such as figure 1 , a particle cutting mechanism for a biomass particle granulator, including a cover, a scraper and a scraper driving device; the shape of the cover is a barrel; the bottom of the barrel-shaped cover has a first through hole, the first through The axis of the hole coincides with the axis of the cover, and the inner diameter of the first through hole is the same as the outer diameter of the feed cover of the biomass granulator; the inner diameter of the open end of the barrel-shaped cover is greater than the outer diameter of the ring die of the biomass granulator; The scraper driving device includes a motor, a large gear and a connecting rod of the large gear; the positions of the large gear and the connecting rod of the large gear are all inside the cover; there are multiple connecting rods of the large gear, which are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com