Screening distributor based on trapezoidal screen bar screen shaft

A distributor and trapezoidal technology, which is applied in the field of screening equipment for coarse and fine materials, can solve the problems of short wear cycle and high motor power, and achieve the effects of less maintenance, less motor power consumption, and simple equipment principle and structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0098] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

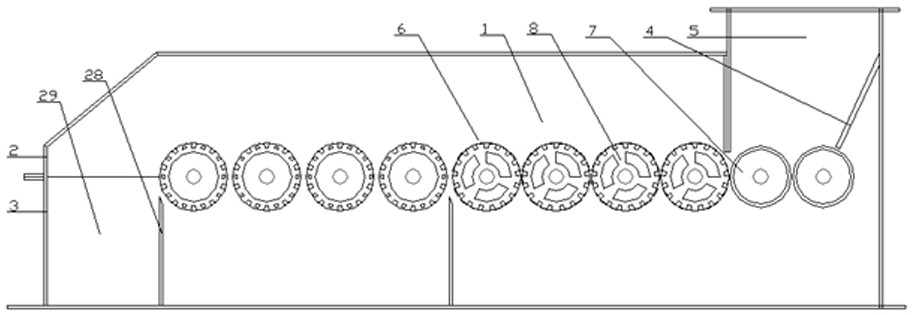

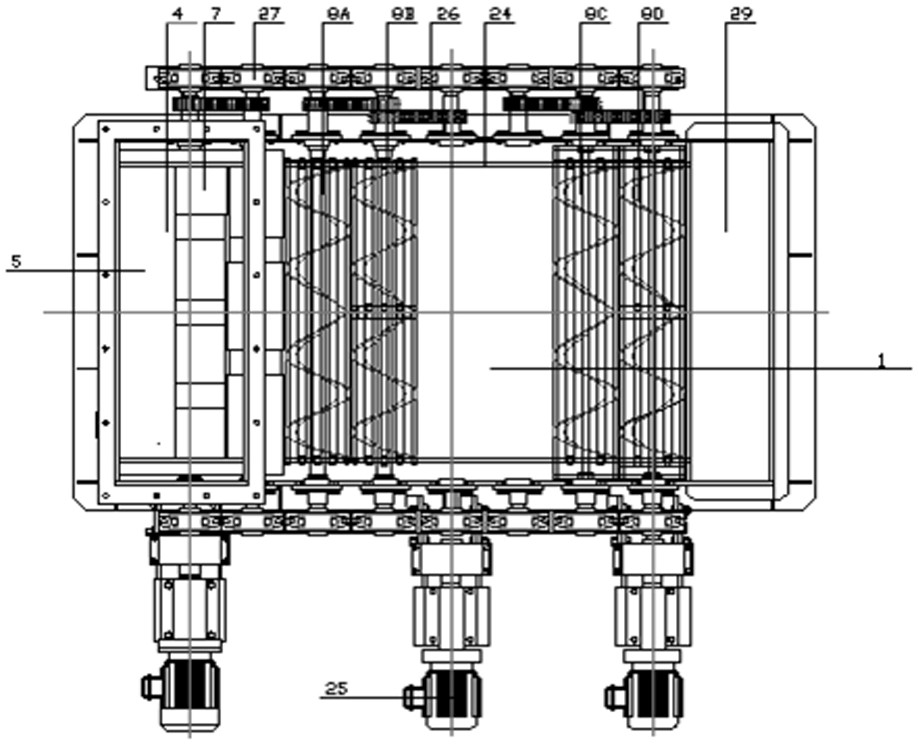

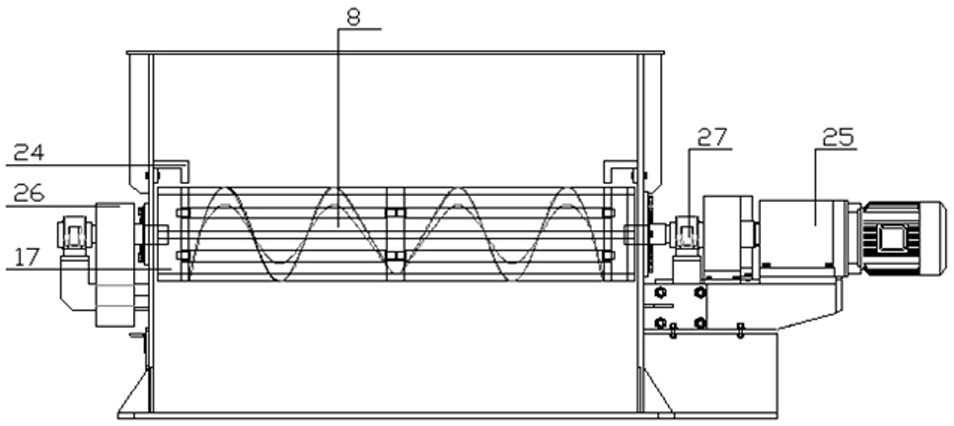

[0099] Such as figure 1 Shown is the main cross-sectional view of the screen distributor 1, which includes an upper casing 2, a lower casing 3, a buffer distribution plate 4, a feed inlet 5, a screen surface 6, an impact-resistant screen shaft 7, and a trapezoidal screen shaft 8. The undersize separation plate 28 and the discharge port 29 are shown through the sieve distributor figure 1 Can understand the main structure, principle and function of each component of the sieve distributor. The material falls from the feed port, and first falls onto the distribution plate and the impact-resistant screen shaft to eliminate the impact force and distribution of the material, and then enters the subsequent trapezoidal sieve bar screen shaft for conveying screening, and the qualified particle size falls to the corresponding under the screen surface. Qualified partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com