Nano-silver composite antibacterial cellulose membrane, and preparation method and application thereof

A cellulose film and composite antibacterial technology, applied in the direction of coating, etc., can solve the problems of poor sterilization effect, coarse particles, uneven dispersion of nano-silver, etc., and achieve good antibacterial effect, high specific surface area, and simple reduction method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The preparation method of nano-silver composite antibacterial cellulose film of the present invention, comprises the following steps:

[0045] (1) Spray the nanocellulose membrane substrate with 100mmol / L silver nitrate solution until the substrate is saturated with moisture;

[0046] (2) Put the moisture-absorbing saturated substrate in a cool place and dry it at room temperature (25°C) for 20 minutes to remove the moisture from the moisture-absorbing saturated substrate, that is, there is no water film on the surface of the substrate, and no water droplets appear by extrusion, and the substrate is incomplete Dry;

[0047] (3) Spray or directly impregnate the base material in step (2) with 50mmol / L ascorbic acid solution, until the base material is just fully soaked, observe the color change of the base material;

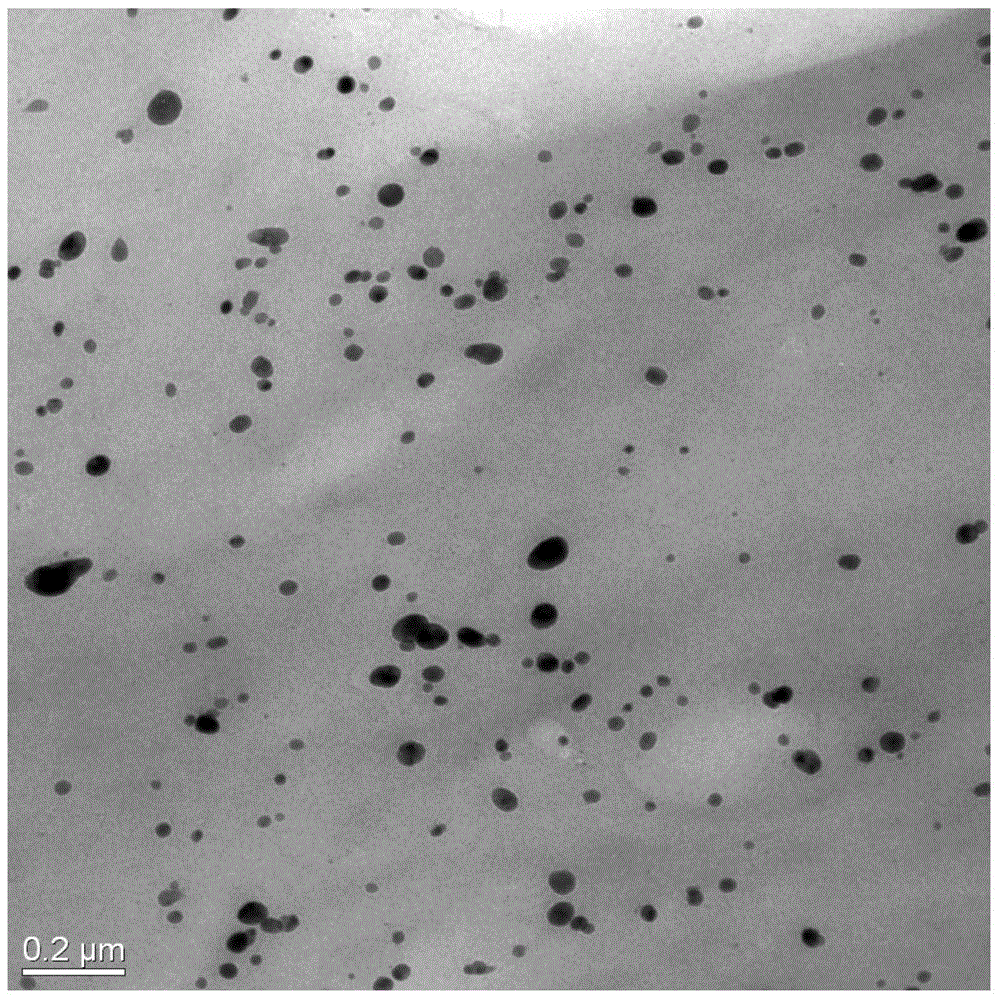

[0048] (4) Take out the base material that has completely turned brown, wash it with water three times, and dry it naturally for 24 hours to obtain the nan...

Embodiment 2

[0051] The preparation method of nano-silver composite antibacterial cellulose film of the present invention, comprises the following steps:

[0052] (1) Spray the micron cellulose membrane substrate with 100mmol / L silver nitrate solution until the substrate is saturated with moisture;

[0053](2) Put the moisture-absorbing saturated substrate in a cool place and dry it at room temperature (25°C) for 20 minutes to remove the moisture from the moisture-absorbing saturated substrate, that is, there is no water film on the surface of the substrate, and no water droplets appear by extrusion, and the substrate is incomplete Dry;

[0054] (3) Spray or directly impregnate the base material in step (2) with 50mmol / L glucose solution until the base material is just fully soaked, and observe the color change of the base material;

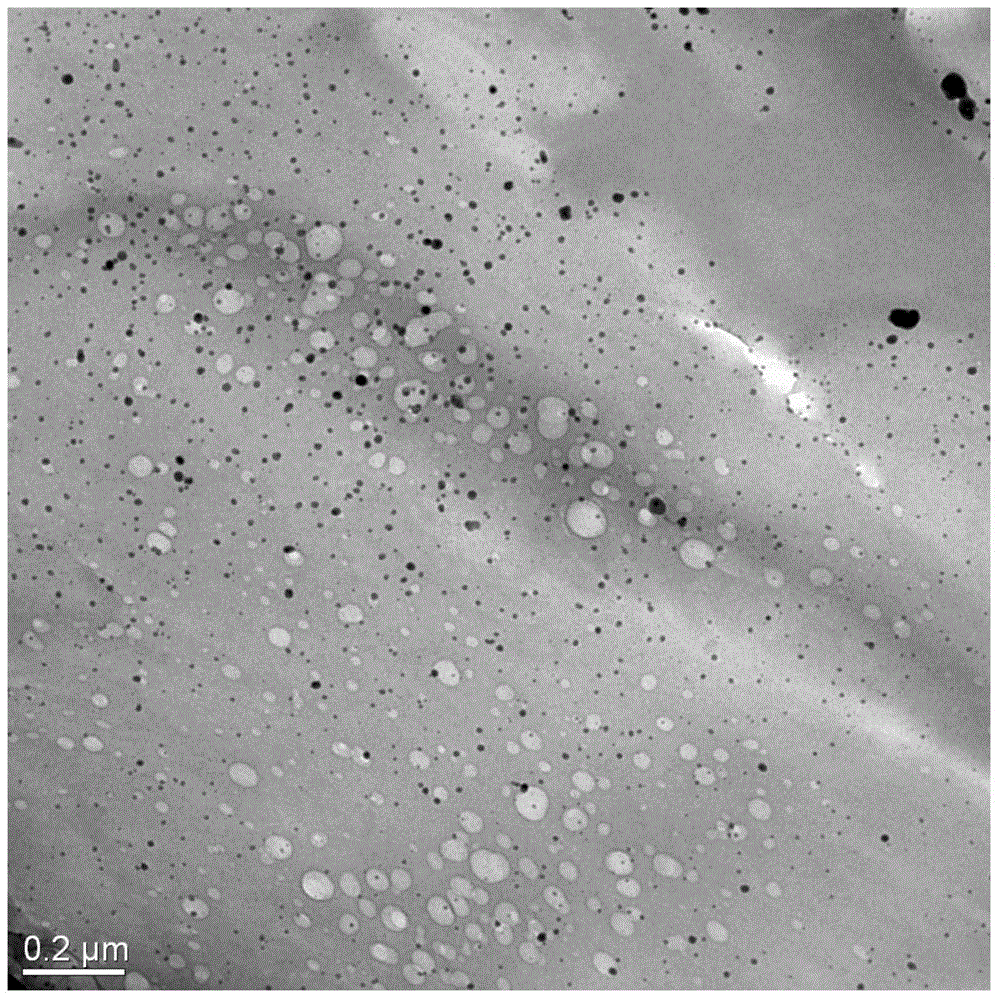

[0055] (4) Take out the base material that has completely turned brown, wash it with water three times, and dry it naturally for 12 hours to obtain the nano...

Embodiment 3

[0058] The preparation method of nano-silver composite antibacterial cellulose film of the present invention, comprises the following steps:

[0059] (1) Spray the micron cellulose membrane substrate with 10mmol / L silver nitrate solution until the substrate is saturated with moisture;

[0060] (2) Put the moisture-absorbing saturated substrate in a cool place and dry it at room temperature (25°C) for 20 minutes to remove the moisture from the moisture-absorbing saturated substrate, that is, there is no water film on the surface of the substrate, and no water droplets appear by extrusion, and the substrate is incomplete Dry;

[0061] (3) Spray or directly immerse the base material in step (2) until the base material is completely soaked with 10mmol / L sodium borohydride solution, and observe the color change of the base material;

[0062] (4) Take out the base material that has completely turned brown, wash it with distilled water three times, and dry it naturally for 24 hours ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com