Method for improving evenness of terylene spunbonded nonwoven fabric and electrostatic filament dividing device

A spun-bonded non-woven fabric, uniformity technology, applied in the direction of non-woven fabrics, textiles and papermaking, etc., can solve the problems of uneven fiber distribution, doubling, tow, adhesion, short separation process, etc., to achieve superiority outstanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

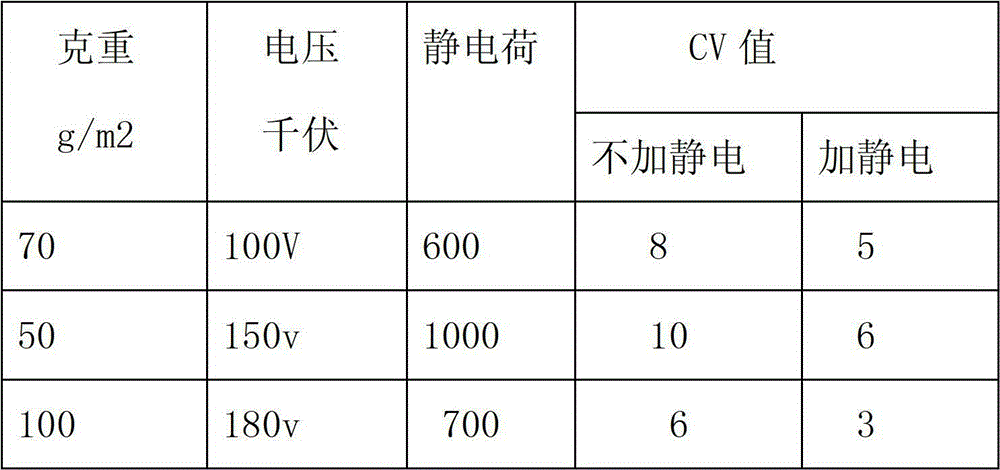

[0014] The method for improving the uniformity of polyester spunbonded nonwoven fabrics of the present invention is to apply a certain amount of heat to the fibers after melt spinning and cooling through an electrostatic discharge rod at the entrance of the drafter of the production equipment of polyester spunbonded nonwoven fabrics. The positive electrostatic charge ensures that the fibers repel each other due to the same charge after leaving the drafter, so that the fibers are separated from each other, reducing the phenomenon of doubling, tow and sticking filaments, and the net curtain after laying is uniform , so as to improve the uniformity of the product; install a static eliminator at the end of the net curtain of the netting machine;

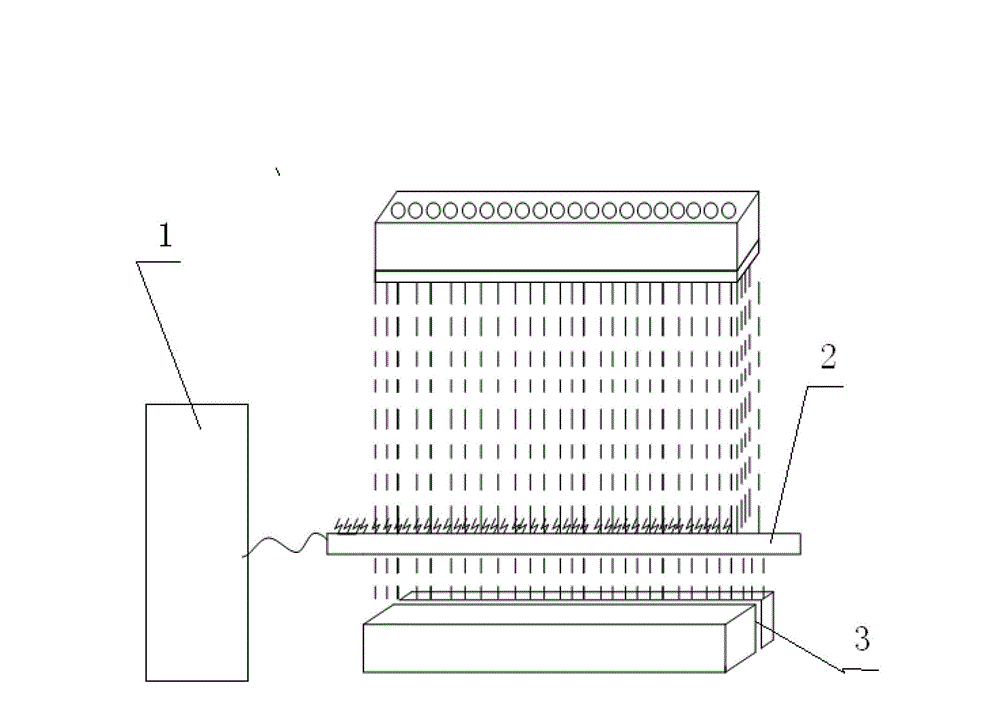

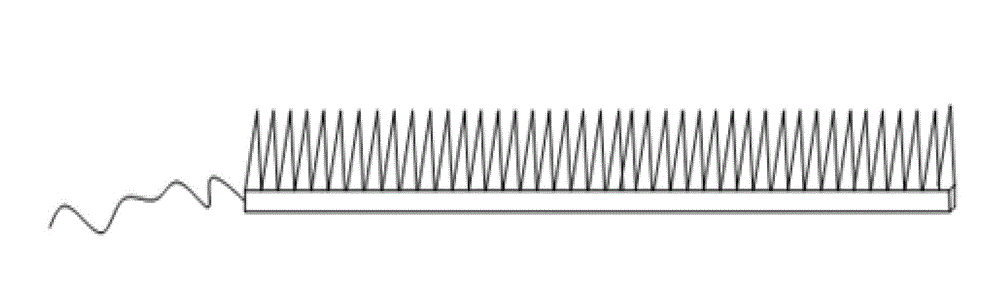

[0015] like figure 1 The shown electrostatic splitting device for implementing the above method is composed of an adjustable electrostatic generator 1 arranged outside the work site and an electrostatic discharge rod 2 installed at 100mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com