High-temperature normal-pressure catalytic reactor suitable for mass spectrometry and application thereof

A technology of catalytic reaction and mass spectrometry, applied in the field of high-temperature and atmospheric-pressure catalytic reactors, can solve the problems of difficult in-situ detection of free radical intermediates, and the inability to obtain real-time and accurate kinetic information of relevant catalytic reaction processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

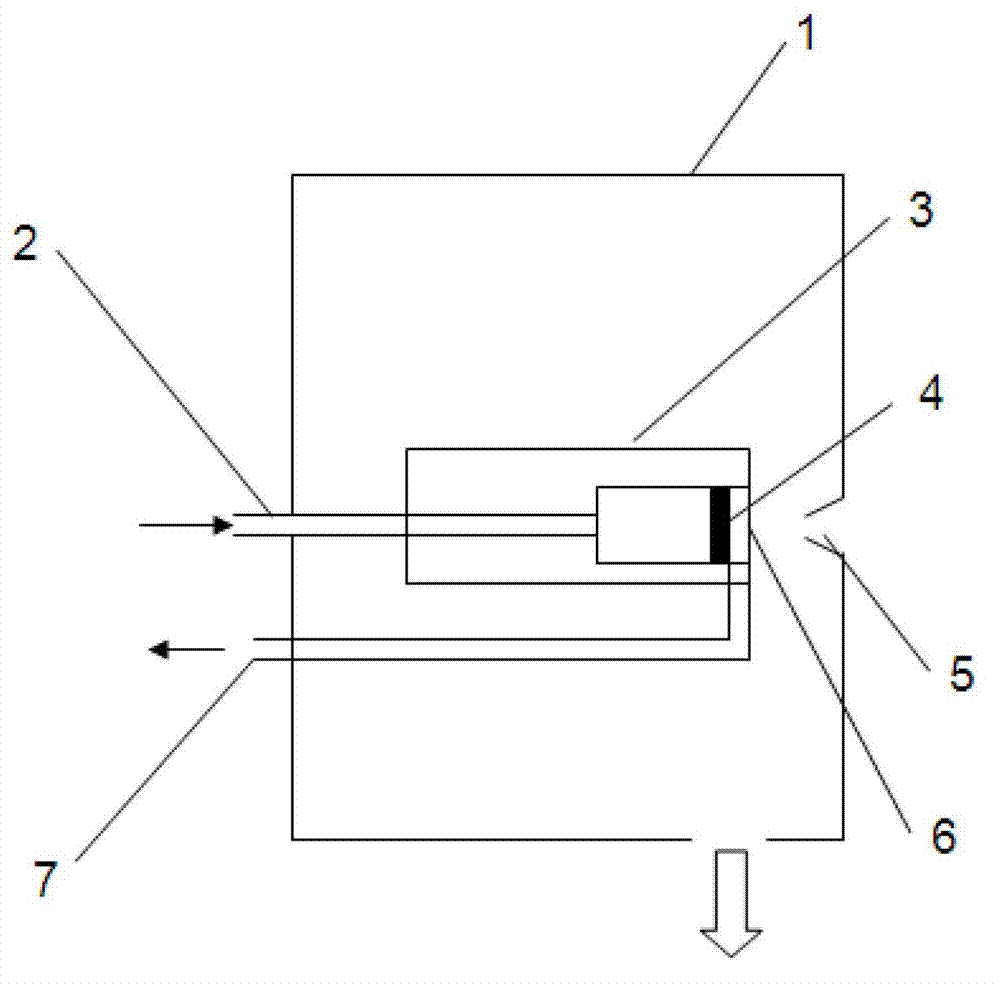

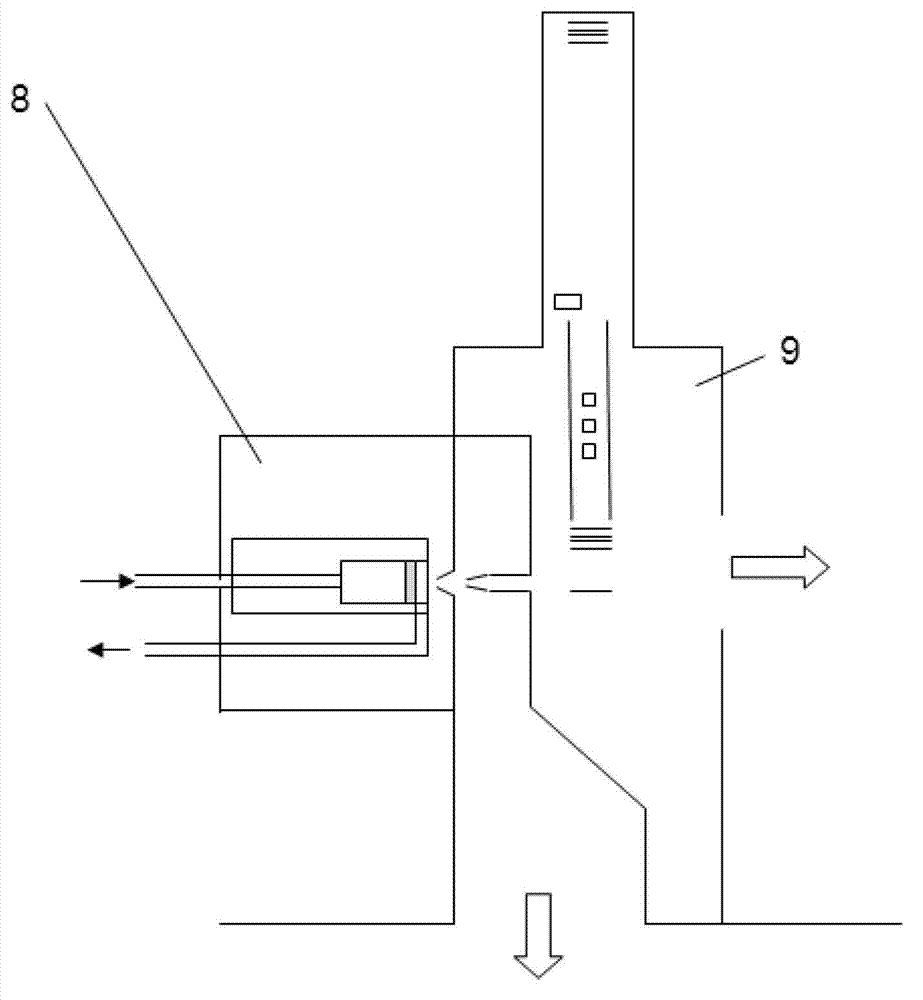

[0014] Such as figure 1 As shown, the present invention is a high-temperature and atmospheric-pressure catalytic reaction furnace suitable for mass spectrometry analysis, including a furnace body, a sampling tube, a high-temperature catalytic chamber, a reaction zone, a differential hole, a micropore and a gas outlet pipe. When the sample reacts in the reaction zone, the sample is catalyzed at different temperatures by adjusting the temperature of the high-temperature catalytic chamber. The catalytic products, free radicals and intermediates diffuse through the micropores to the ionization chamber due to the pressure. When passing through the differential hole Molecular beams are then formed and enter the ionization chamber of the mass spectrometer. During the reaction, gas is continuously inflated into the injection tube to keep the reaction zone at normal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com