Closing method of shock absorber support seat

A support seat and shock absorber technology, applied in the directions of transportation, packaging, vehicle parts, etc., can solve the problems of large diameter, thick-walled support seat and difficult to close the shock absorber support seat, etc., and achieve the effect of preventing radial rotation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

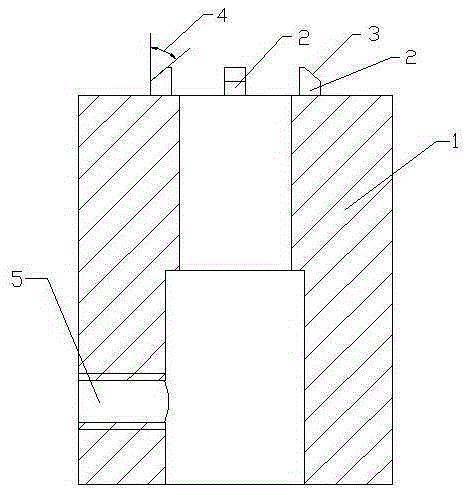

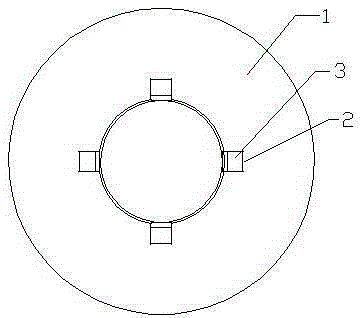

[0020] Such as figure 1 with 2 As shown, the shock absorber support seat closing tooling includes a tooling body 1, wherein the tooling body 1 is a hollow cylinder structure, and its inner diameter is the same as that of the shock absorber piston rod. There are a plurality of bosses 2, and the top surface 3 of the bosses is an inclined surface at a certain angle with the axis of the tooling body 1.

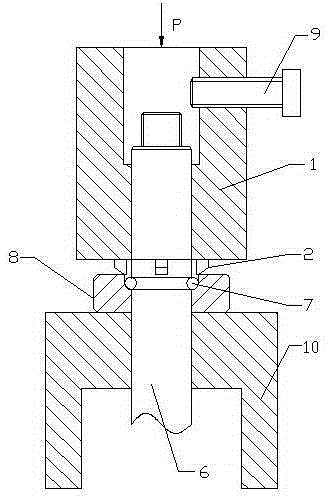

[0021] Use this closing tool to close the open end of the support seat, which is carried out on a press. At first the support base 8 to be closed is installed on the shock absorber piston rod 6, as image 3 As shown, the whole shock absorber assembly is placed on the compression fixture 10, so that the end face of the support seat 8 is pressed against the end face of the compression fixture 10. The closing tool is installed on the press, and the screw 9 is used to utilize the threaded hole 5 on the closing tool to fix the closing tool on the pressure bar of the press. Since th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com