Forming mold for shutter

A technology for forming molds and louvers, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of small heat dissipation hole area and unfavorable continuous processing of plates, so as to facilitate replacement and assembly, save production costs, and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

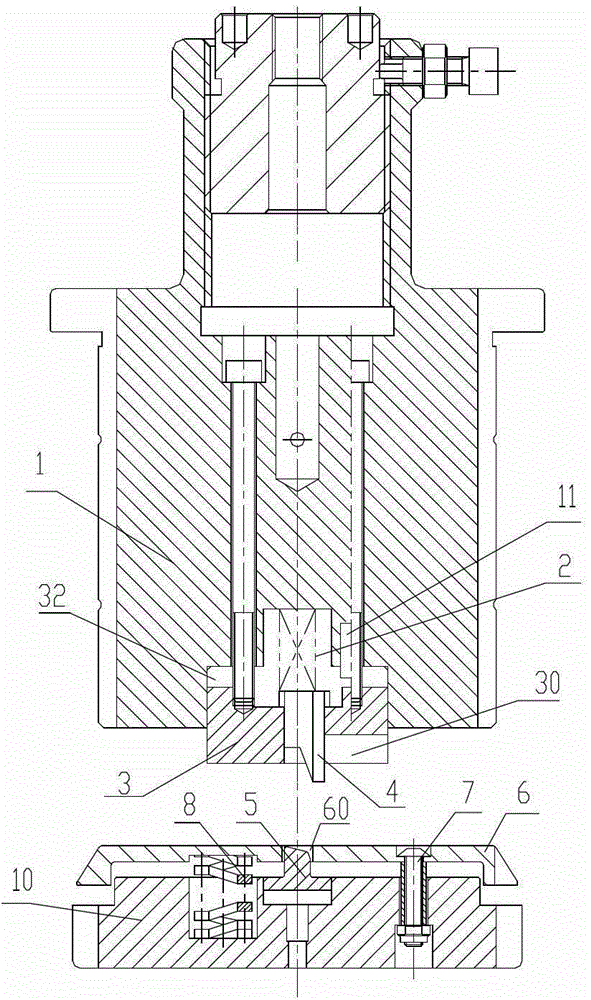

[0031] The invention as Figure 1-13 As shown, it includes an upper mold body 1, a forming die 3, a forming punch 5 and a lower mold body 10, and also includes an elastic forming mechanism and a discharge mechanism;

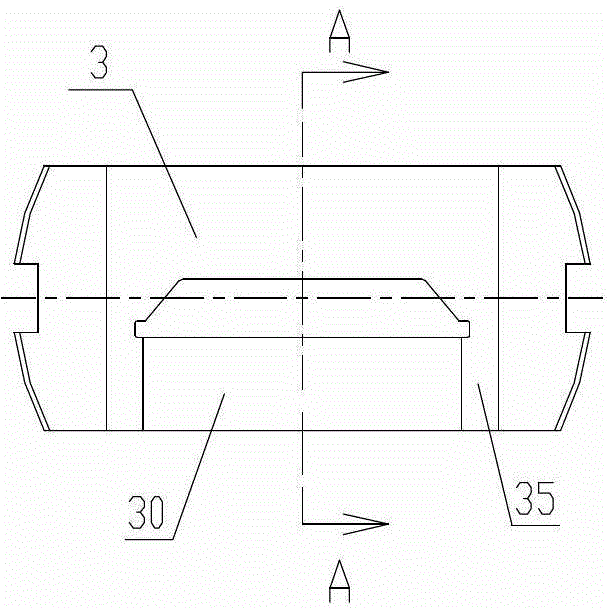

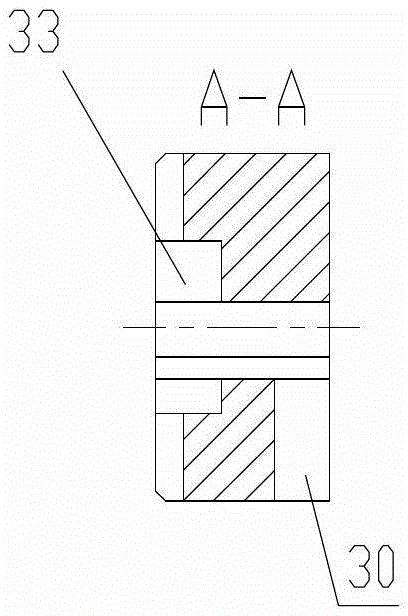

[0032] The elastic forming mechanism includes a forming block 4 and a return spring 2; the bottom of the forming block 4 is provided with an inclined wedge surface, and the inclined wedge surface faces the feeding direction of the louver; the forming die 3 is embedded The structure is fixedly connected to the bottom of the upper mold body 1; the middle part of the forming die 3 is provided with a through groove 31, and the cross-sectional shape of the through groove 31 matches the cross-sectional shape of the molding block 4 body, so that the The molding block 4 can reciprocate up and down relative to the through groove 31; the return spring 2 is arranged between the molding block 4 and the upper mold body 1; the bottom surface of the molding die 3 faces the A r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com