Method for strengthening process rigidity of thin-wall blade based on non-uniform allowance

A non-uniform blade technology, applied in the field of enhancing the rigidity of thin-walled blades, can solve problems such as deformation, and achieve the effects of solving insufficient rigidity, reducing cutting deformation, and reducing machining errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] This embodiment is a method for enhancing the process rigidity of a thin-walled blade based on a non-uniform margin.

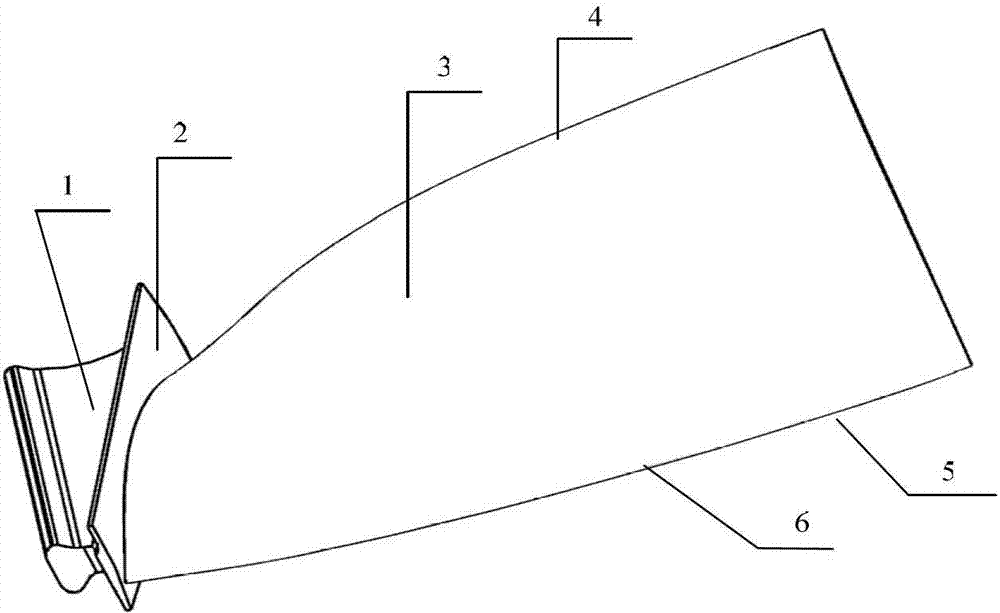

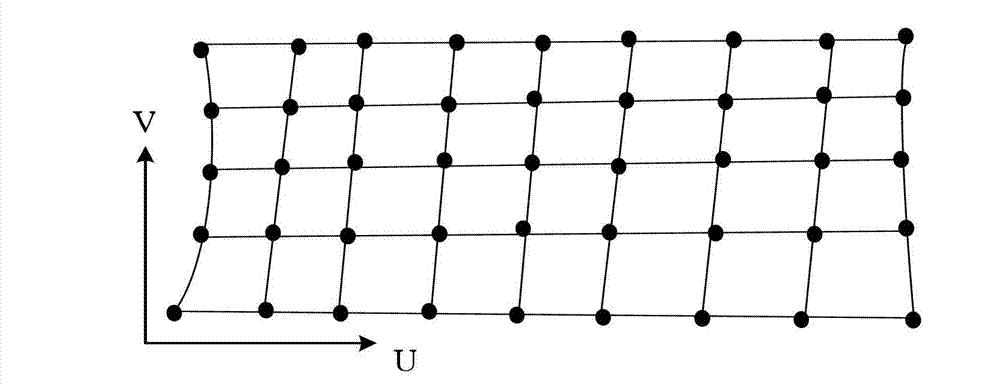

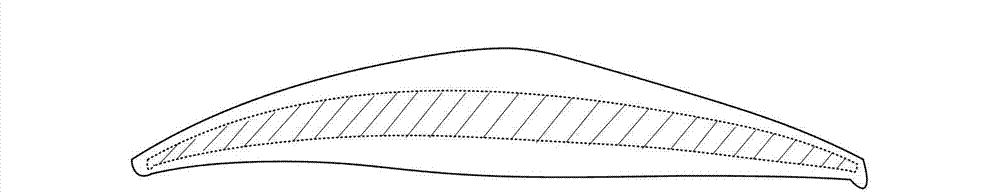

[0027] See figure 1 , figure 2 , image 3 , Figure 4 The method of the present invention for enhancing the process rigidity of thin-walled blades based on non-uniform margins is based on the perspective of adjusting the process rigidity of the blank before the finishing of thin-walled blades, and optimizes the distribution method of the blade finishing allowance according to the method to reduce the thickness Cutting deformation in the finishing process of wall blades reduces machining errors.

[0028] In the milling of thin-walled blades, since the cutting force is mainly determined by factors such as the depth of cut, width of cut, and feed per tooth, under other conditions unchanged, where the finishing allowance is small, the depth of cut is small. The resulting cutting force is also small. If the thin-walled blade finishing allowance distribution i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com