Precision machining method for helical tooth planet row

A precision machining and planetary row technology, applied in the field of gearboxes, can solve the problems of frame position deviation, planetary gear inner hole cylindricity, and planetary gear shaft outer cylindricity, etc., to improve the pass rate and The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

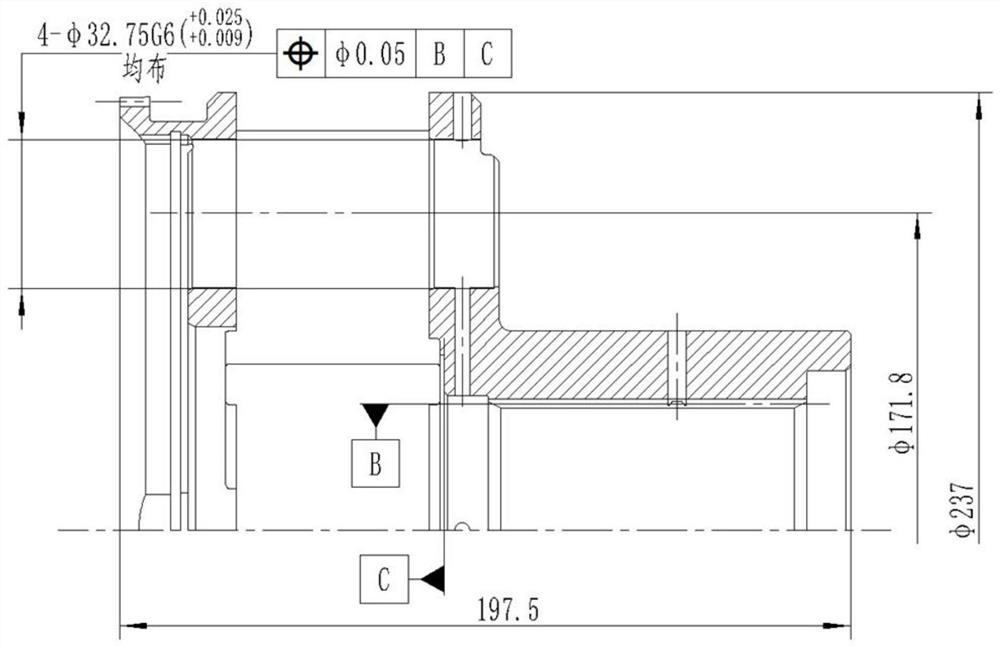

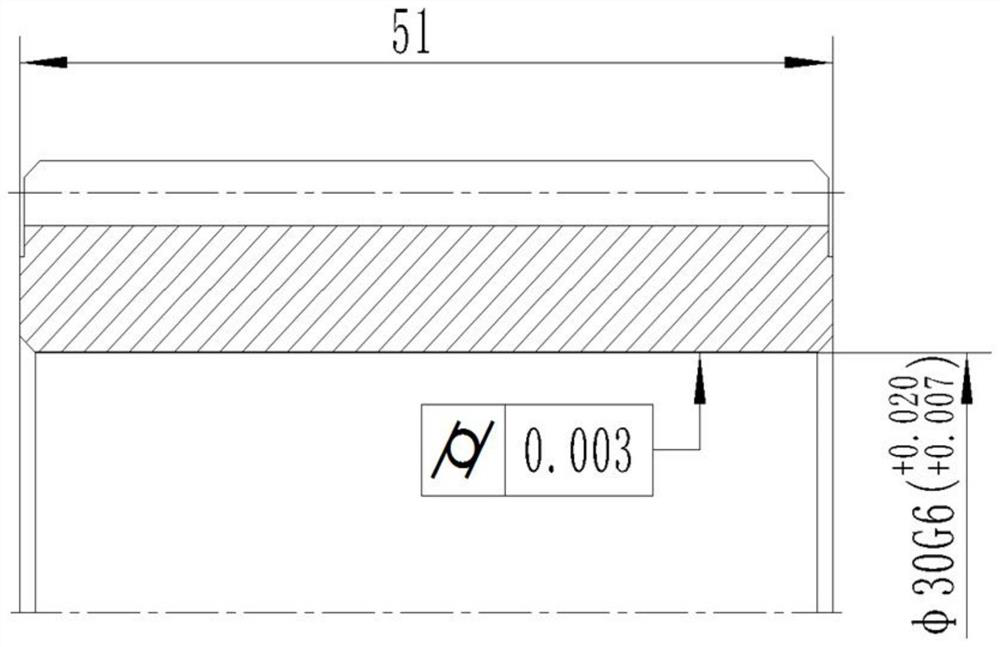

[0019] see figure 1 and figure 2 , the material of the planetary frame in this embodiment is ZG270-500GB / T11352-1989, the four planetary shaft hole positions are seriously out of tolerance after being processed by the existing technology, and it is difficult to meet the 0.05 requirement of the drawing. see image 3 and Figure 4 , In this embodiment, the planetary gear and planetary gear shaft material 17Cr2Ni2H-Q / LP117-2000, in order to meet the requirements of hardened layer depth EHT610 0.2-0.5mm and surface hardness ≥ 58HRC, carburizing and quenching are required. The inner hole of the planetary gear is 51mm deep, the diameter is φ30G6mm, and the aspect ratio is 1.7. Similarly, the aspect ratio of the planet wheel shaft is 84 / 22=3.88, which belongs to the slender shaft, and the cylindricity of 0.003 is difficult to achieve.

[0020] This embodiment provides a precision machining method for a helical planetary row, including the following steps:

[0021] 1) Processing...

Embodiment 2

[0028] This embodiment provides a precision machining method for a helical planetary row, including the following steps:

[0029] 1) Processing thin-walled ring gear.

[0030] 2) Process the planetary frame. Among them, the planetary frame is subjected to the grinding process after finishing the shape finishing. The planetary frame is clamped based on the inner hole and the end face, and the shallow hole drilling is selected to set the preset hole as the technological hole when boring. Use a semi-finish boring tool and a fine boring tool to process the planetary shaft hole. By changing the machining datum and selecting appropriate machining tools and cutting parameters, the position of the planetary shaft hole of the frame is improved to ensure that the product design requirements are met.

[0031] 3) Processing planetary gears. Among them, the grinding process of planetary gear teeth is divided into rough grinding and fine grinding. Grinding wheels of different grain siz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com