Processing method of thin-walled fan shell with holes and workpiece positioning tool

A processing method and thin-walled technology, applied in the direction of positioning devices, metal processing machinery parts, metal processing equipment, etc., can solve the problems of difficulty in stabilizing the forming accuracy of thin-walled parts, the influence of forming accuracy, and the complexity of the process, so as to achieve stable processing, Simple clamping and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

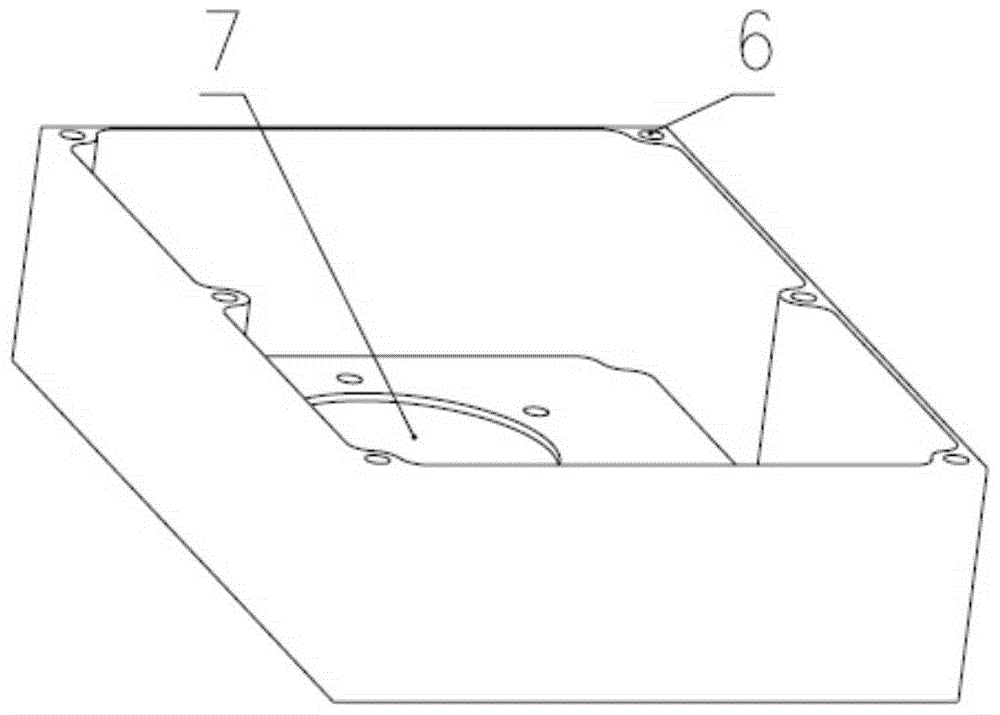

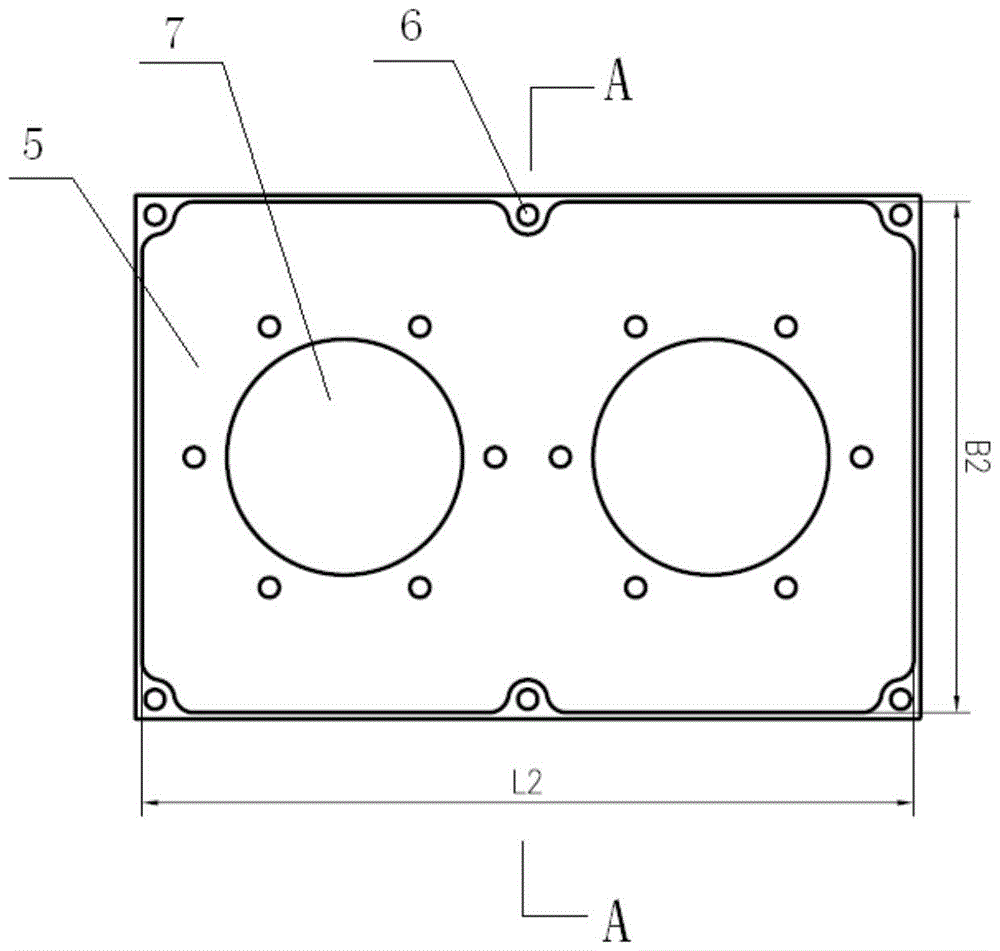

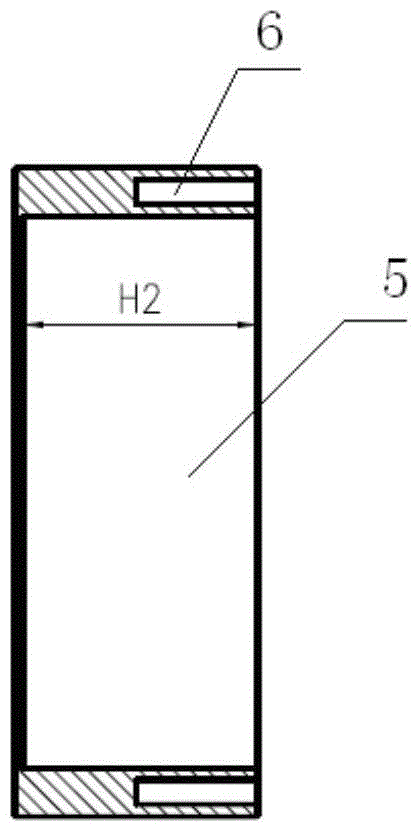

[0032] The schematic diagram of the workpiece positioning tool used in the processing method of the thin-walled fan casing with holes of the present invention is as follows Figure 5-Figure 7 shown. The tooling used in the processing method of the present invention comprises an integral base 9 and a support body 11, and grooves 12 are respectively arranged at positions opposite to the workpiece threaded holes of the support body 11, and the outer contour of the support body 11 is in line with the described support body 11. According to the shape corresponding to the workpiece cavity, threaded through holes are respectively arranged on the base 9 opposite to the workpiece threaded holes, and the screws 10 pass through the threaded through holes and are threadedly connected with the threaded holes on the workpiece. The upper surface 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com