Print drying machine

A technology of drying device and blowing device, applied in printing, printing presses, general parts of printing machinery, etc., can solve the problems of uneven drying position of products, not obvious product drying, product working defects, etc. Quick drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

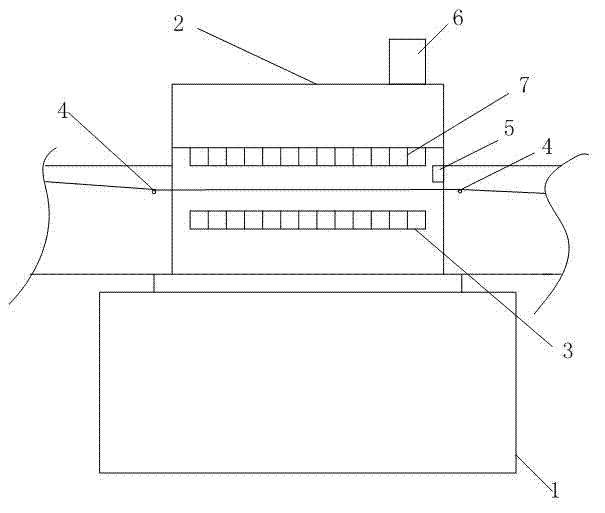

[0013] Such as figure 1 As shown, the printing and drying device includes a base 1, a drying device 2 is provided on the base 1, and a pair of infrared lamps are provided in the drying device 2, an upper infrared lamp 7 and a lower infrared lamp 3 distributed up and down, and the upper infrared lamp 7 and There are at least 12 pairs of lower infrared lamps 3, and guide wheels 4 are provided at the inlet and outlet of the drying device 2, and products are connected between the inlet and outlet of the drying device 2 through the guide wheel 4. And through the infrared lamps distributed up and down, the product at the discharge port is connected with the rewinding device, which can quickly and effectively dry the product. At the same time, a drying device is provided in the drying device 2 and at the discharge port of the drying device 2 The temperature device 5 is connected with the control device provided on the drying device 2, and can effectively and controllably control the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com