Suspended suspension device, manufacturing method applied for plastic tubular fabric and tubular mesh fabric and finished product thereof

A manufacturing method and cylindrical cloth technology are applied in the manufacturing field of plastic cylindrical cloth and cylindrical mesh cloth products, which can solve the problem of adhesion of two corresponding surfaces, inability to separate cylindrical mesh fabrics, and inability to perform flat mesh fabric processing. methods and other issues to achieve the effect of improving convenience and brand recognition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

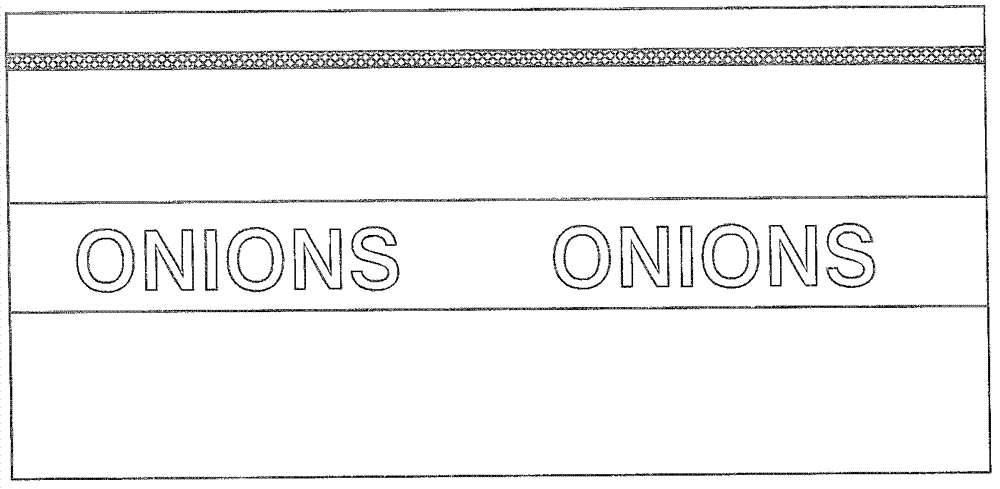

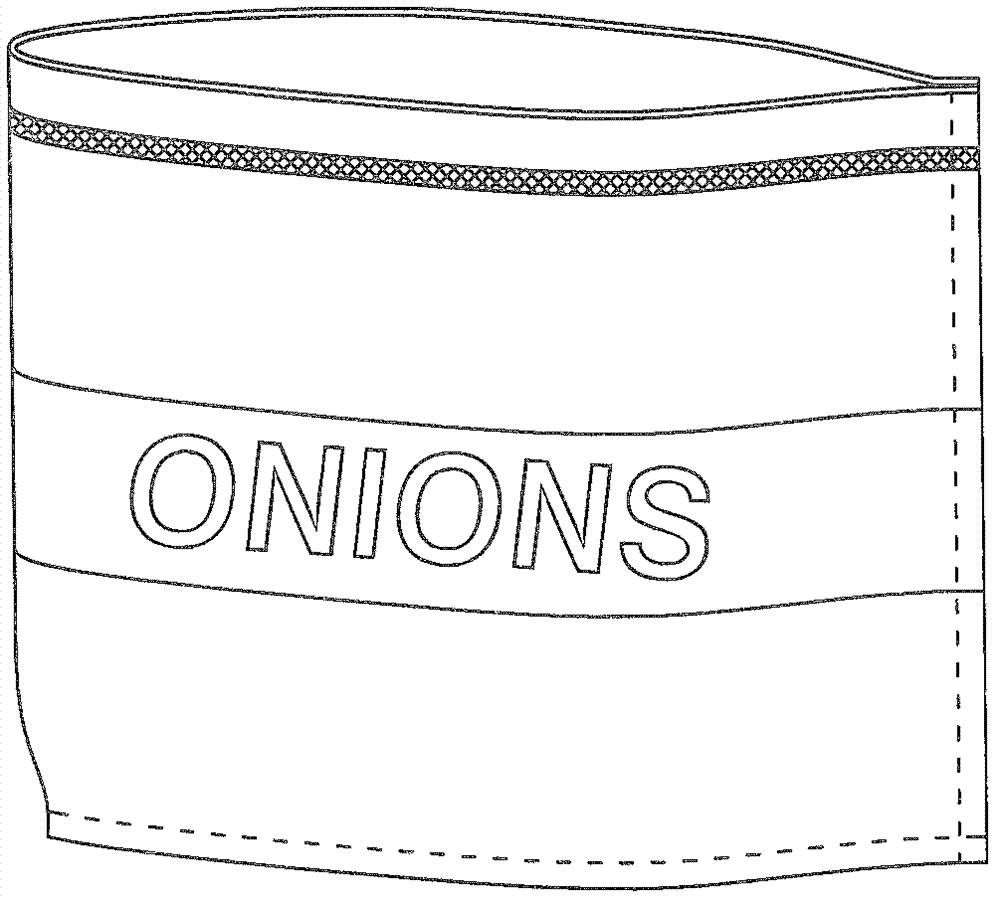

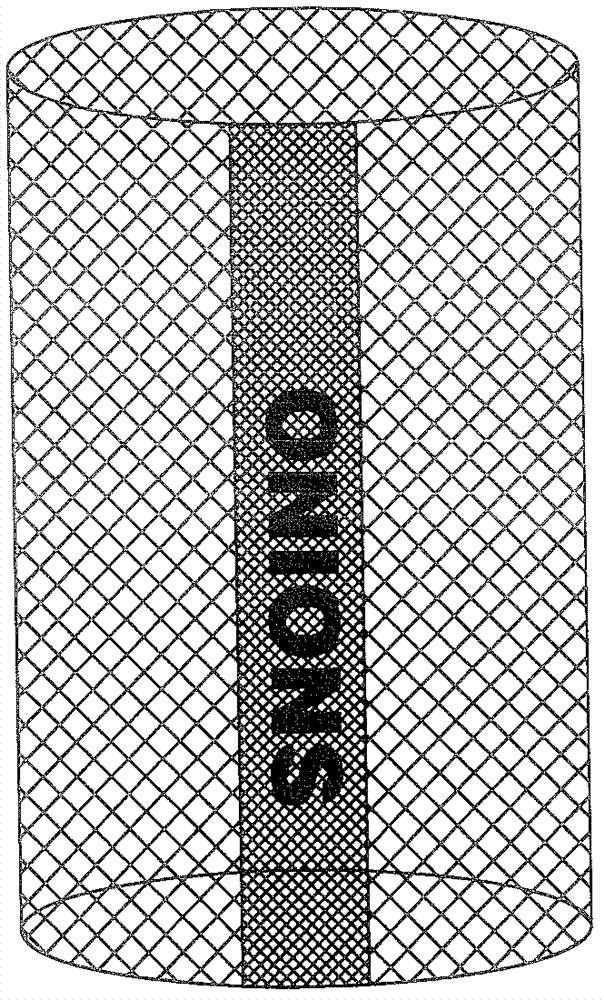

[0045] Please refer to Figure 6 , a schematic diagram of a plastic cylinder mesh bag with a horizontal pattern label of the present invention, the above-mentioned cylindrical cloth with a horizontal pattern label is cut at the plastic film 302 to obtain a bag with an open end 304 and a bottom end of the bag 303 is a plastic cylindrical mesh bag, wherein, at the bottom 303 of the bag, the bottom of the bag is sewn with sewing thread, and the sewing strength of the sewing thread is improved through the plastic film 302, reducing the probability of the bottom of the bag being damaged due to gravity. In addition, at the opening end 304, the plastic cylindrical mesh bag can be sewn by a packaging machine with the function of sewing, that is, a plastic cylindrical mesh bag with a horizontal pattern label is completed.

Embodiment 2

[0047] Please refer to Figure 7A , a schematic diagram of a plastic cylinder mesh bag with a horizontal pattern label and a drawstring of the present invention. As described in Embodiment 1, at the bottom end 303 of the bag, the bottom of the bag is sewn with sewing thread, and the suture strength of the sewing thread is improved through the plastic film 302 to reduce the probability of the bottom of the bag being damaged due to gravity. Its difference is that, the bag mouth place fits a drawstring plastic film that does in advance (referring to Figure 7B ), a stay cord 305 is arranged between the interlayers of the stay cord plastic film, and when the stay cord plastic film is attached to the mouth of the bag, the stay cord can be fixed at the mouth of the bag for easy access by the user.

[0048] In addition, at the opening end 304 of the plastic cylinder mesh bag, the joint of the drawstring plastic film needs to be wider than the width of the bag mouth, so that the draw...

Embodiment 3

[0050] see Figure 9 , at first, like the manufacturing method of embodiment 1, obtain a plastic cylinder net bag with horizontal pattern label, further, pass the dividing plate of suspension hanger assembly, in order to separate the two sides of plastic cylinder net bag, make the The hole device 38 passes through the perforation 39 on the dividing plate, and carries out the punching step on the plastic film 302 of the plastic cylinder mesh bag, and forms a plurality of holes 302a on the plastic film 302 of the opening end 304 of the plastic cylinder mesh bag, and can be carried out subsequently. In the stringing step, a lifting rope is provided as a plastic cylindrical mesh bag.

[0051] Through the manufacturing method of the present invention, the cylindrical cloth achieves the lamination of the horizontal pattern label, and also solves the problems of the cutting edges of the mesh cloth being scattered and the ropes. In addition, the manufacturing method of the present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com