A kind of flavored color wrapping paper and preparation method thereof

A technology of wrapping paper and color, applied in the field of packaging industry, can solve the problems of difficult fragrance of wrapping paper and easy escape of essence, and achieve the effects of low cost, reduction of escape speed, and improvement of brand recognition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

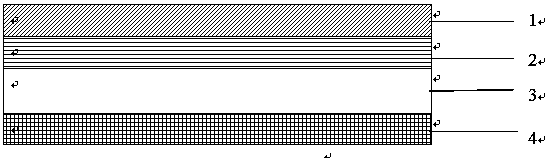

Image

Examples

preparation example Construction

[0051]Another aspect of the present invention discloses a method for preparing scented colored wrapping paper, comprising the steps of:

[0052] (1) Preparation of flavored color paint: Take polyvinyl alcohol aqueous solution, natural plant essence extract and water in sequence, add them to the reaction kettle, stir for 10 minutes, then raise the temperature to 50°C, add glutaraldehyde, and continue stirring for 4 hours;

[0053] Continue to add water-based acrylic ester copolymer emulsion, natural pigment, wetting agent and defoamer to the reaction kettle, and stir for 1 hour to prepare a scented color paint.

[0054] (2) Preparation of varnish: Take polyvinyl alcohol aqueous solution, natural plant essence extract and water in sequence, add them to the reaction kettle, stir for 10 minutes, then raise the temperature to 60°C, add succinaldehyde, continue stirring for 4 hours, and continue to react Add water-based polymers, wax additives, wetting agents and defoamers into the ...

Embodiment 1

[0058] (1) Take 20kg of polyvinyl alcohol 1788 aqueous solution, 2kg of natural mint essence extract and 10.85kg of water in turn, add them to the reaction kettle, stir for 10min, then raise the temperature to 50°C, add 0.15kg of glutaraldehyde, continue to stir for 4h, and continue to Add 60kg of methyl methacrylate / ethyl acrylate / butyl acrylate copolymer emulsion, 3kg of sodium copper chlorophyllin, 2.5kg of Dispers 740 wetting agent and 1.5kg of TEGO Airex 902w defoamer into the reaction kettle, and stir for 1 hour to obtain Peppermint light green paint;

[0059] (2) Take 5kg of polyvinyl alcohol 2088 aqueous solution, 0.1kg of natural mint essence extract and 12.32kg of water in turn, add them to the reaction kettle, stir for 10 minutes, then raise the temperature to 60°C, add 0.08kg of succinic aldehyde, continue to stir for 40 minutes, continue Add 80 kg of self-crosslinking styrene-acrylic emulsion, 1 kg of E-842N wax additive, 1 kg of TEGO Wet KL245 wetting agent and 0...

Embodiment 2

[0063] (1) Take 35kg of polyvinyl alcohol 1788 aqueous solution, 0.1kg of natural coffee essence extract and 26.32kg of water in sequence, add them to the reaction kettle, stir for 10 minutes, then raise the temperature to 50°C, add 0.08kg of glutaraldehyde, continue stirring for 4 hours, continue Add 36kg of methyl methacrylate / butyl acrylate / acrylic acid copolymer emulsion, 1kg of red bean hull brown pigment, 1kg of Dispers 740 wetting agent and 0.5kg of TEGO Airex 902w defoamer into the reaction kettle, stir for 1h, and make coffee Fragrant beige paint.

[0064] (2) Take 15kg of polyvinyl alcohol 2088 aqueous solution, 0.5kg of natural coffee essence extract and 5.38kg of water in turn, add them to the reaction kettle, stir for 10 minutes, then raise the temperature to 60°C, add 0.12kg of succinic aldehyde, continue stirring for 40 minutes, continue Add 70kg of acrylate-modified polyurethane emulsion, 5kg of wax additive, 2.5kg of TEGO Wet KL245 wetting agent and 1.5kg of B...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com