Insulating material shell and electric connector

A technology of insulating materials and shells, which is applied in the direction of connection, parts of connection devices, circuits, etc., can solve the problems of insufficient tightness of installation, high efficiency, difficult installation limit, single assembly method, etc., and achieve high-efficiency disassembly and docking , Improve assembly performance and improve coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

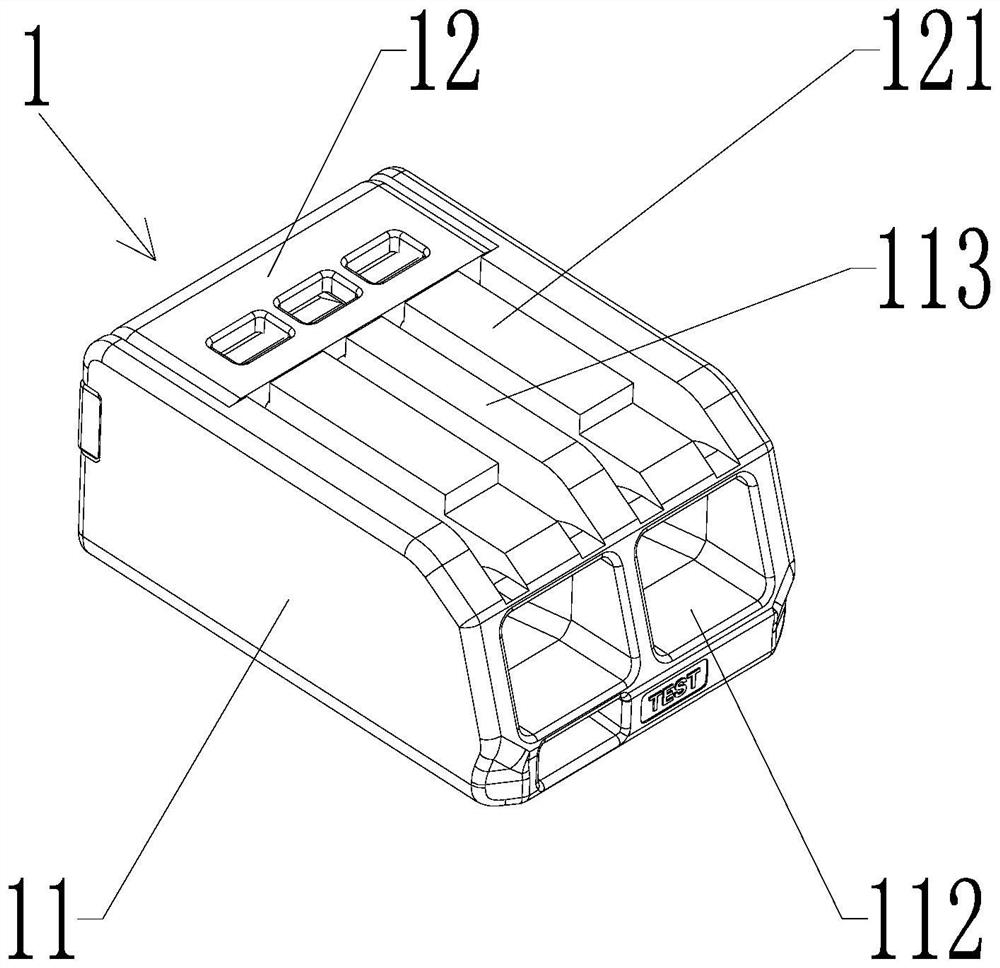

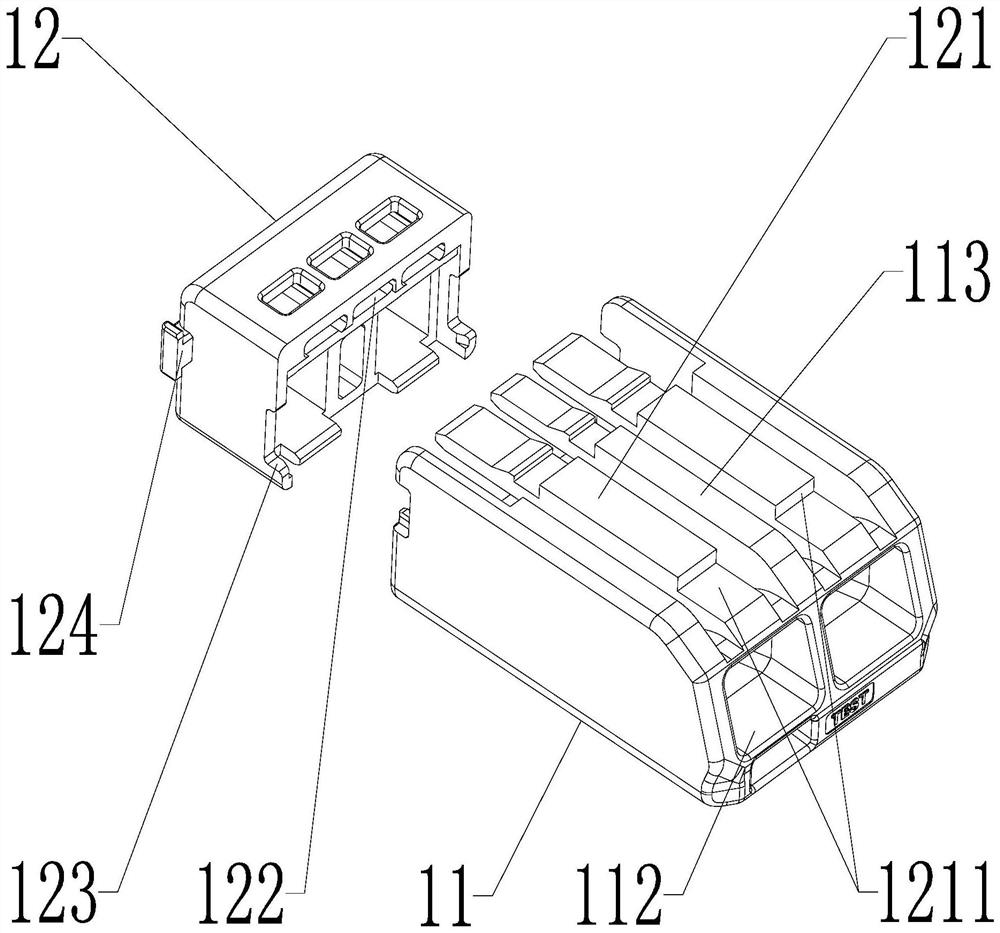

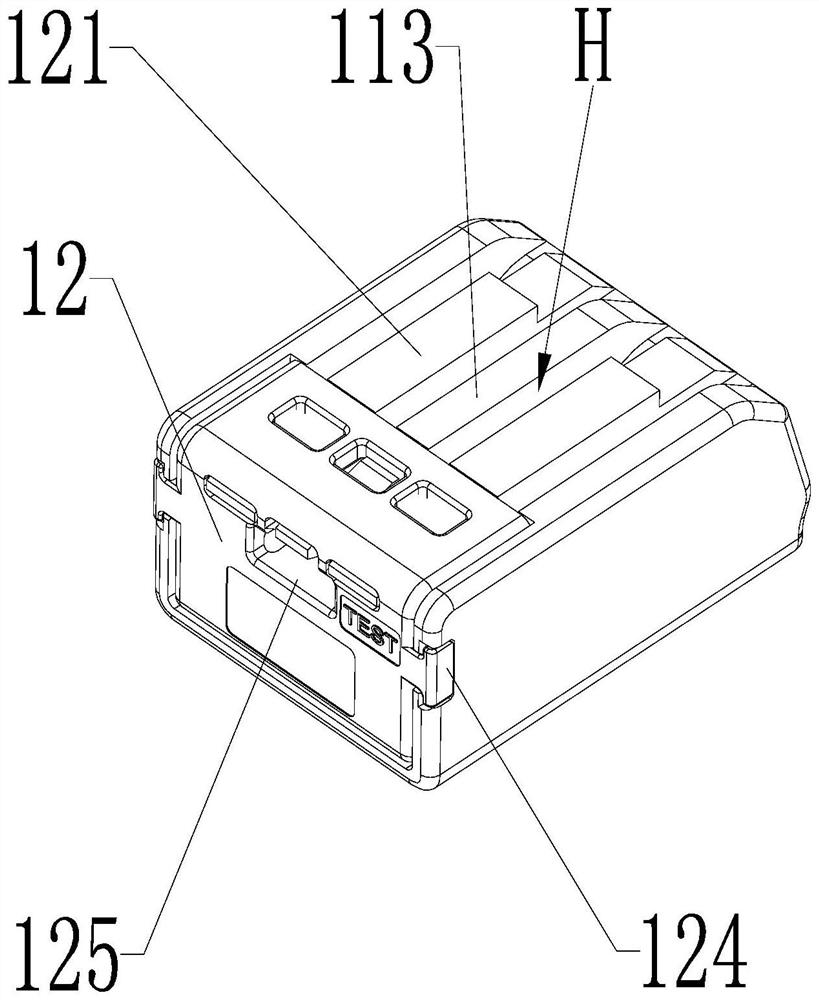

[0044] combine Figure 1 to Figure 3 ,as well as Figures 6 to 8 , This embodiment provides an insulating material casing, including a plastic casing body. The main body of the plastic case is provided with a base 11 and a cover 12 that is adapted to the base 11 . One side of the base 11 is provided with a plug-in hole 112 , and the cover 12 is detachably engaged and arranged in the base 11 . The other side. The outer wall sections 121 and the partitions 113 are formed on the main body of the plastic shell at intervals. Wherein, any plug hole 112 is assigned with external wall segments 121 that are opposite to each other, the cover body 12 and the base 11 are aligned and matched with each other, and after the docking, the external wall segment 121 is shielded above the base 11, so that the The plug-in space formed in the main body of the plastic shell is covered.

[0045]In the above, the base 11 and the cover 12 are engaged with each other to form the entire shell structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com