Modular combined-type tower crane attached bar with extensive stepless adjustment-type length

A combined tower crane and stepless adjustment technology, applied in the direction of cranes, etc., can solve the problems that the length of the attachment rod cannot meet the requirements of on-site installation, the use of tower crane attachment devices is large, and the tower crane attachment devices are different, etc. The effect of environmental protection, manpower saving and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

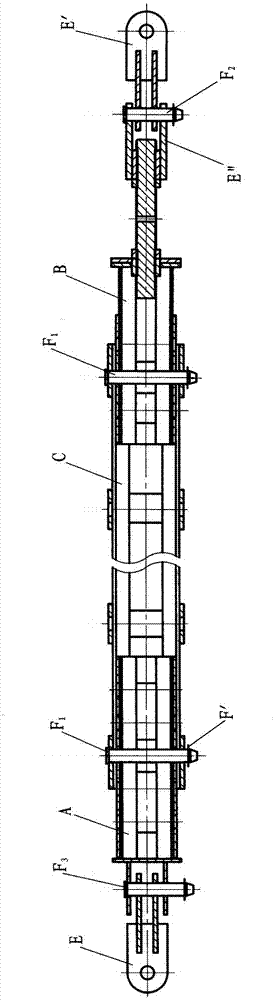

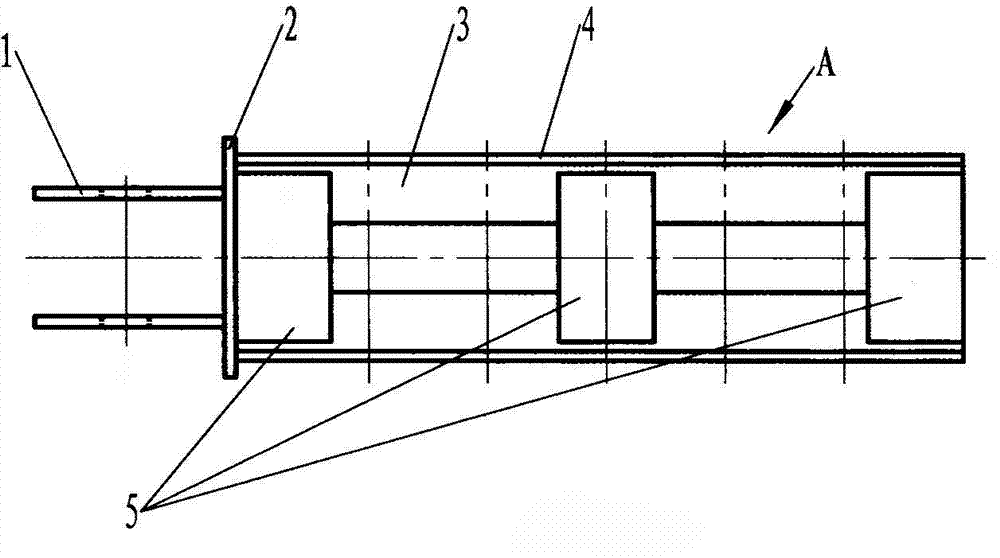

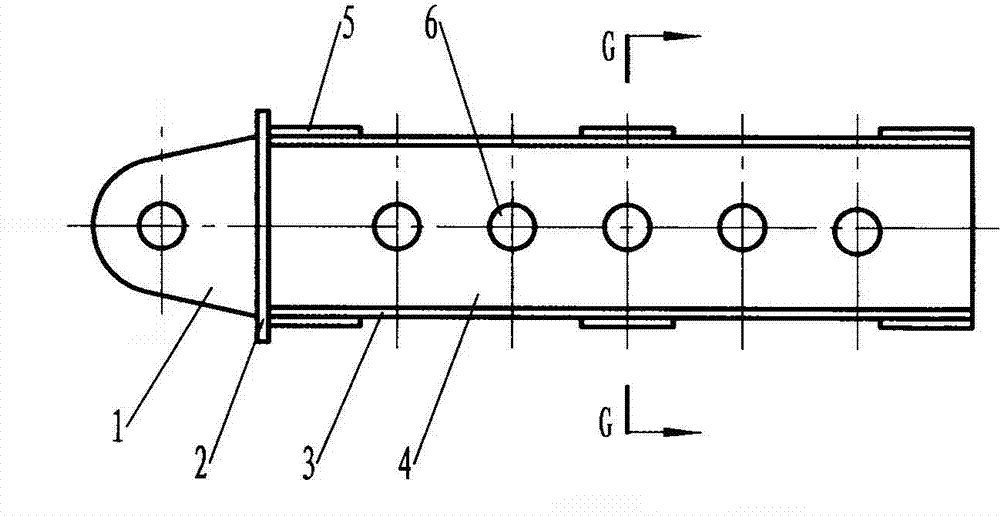

[0041] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 As shown, the first embodiment of the present invention has an upper connector E connected to the wall embedded parts, a lower connector E' connected to the ring beam of the tower body, and the lower connector E' through the second pin F 2 Hinged lead screw adjustment device E", through the third pin shaft F 3 The rod head A hinged with the connector E, the rod tail B connected (fixed connection) with the lead screw adjustment device E″, the first shaft C (and the second shaft D). In this way, the rod head A is connected through the upper The part E is connected with the embedded part of the wall, and the rod tail B is connected with the ring beam of the tower body through the screw adjusting device E″ and the lower connecting part E′. A first shaft C or a combination of two first shafts C and one second shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com