Composition for polymer film and polymer film and multilayer film

A polymer film and composition technology, applied in the direction of synthetic resin layered products, layered products, chemical instruments and methods, etc., can solve the problems of mutual adhesion, high initial heat sealing temperature of the film, and adverse effects of the processing process, etc. Achieve good film-forming properties, low initial heat-sealing temperature, and good heat-blocking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0107] This example serves to illustrate compositions for polymer films and polymer films and multilayer films according to the invention.

[0108] (1) Preparation of propylene polymer

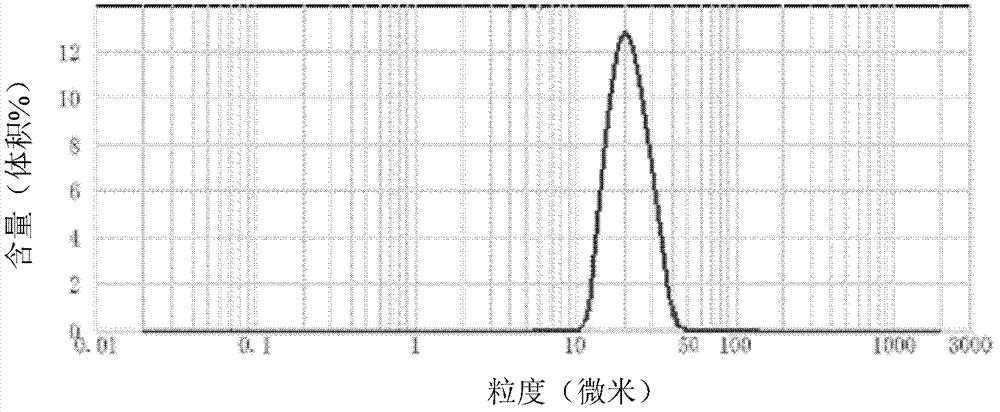

[0109] Adopt commercially available catalyst solid components from Beijing Aoda Petrochemical Co., Ltd., and sieve the catalyst solid components before use, so that the particle size of the catalyst solid components is 10-50 microns, and the particle size is 14-30 The amount of solid components within the range of microns is 87% by volume; as figure 1 As shown, the particle size distribution curve of the collected solid components is a unimodal distribution.

[0110] Based on the total amount of the solid components, the content of titanium in the solid components is 2.5% by weight, and the content of di-n-butyl terephthalate is 9% by weight.

[0111] Continuously feed the catalyst solid component at 0.61g / h for 50m 3 In the continuous horizontal stirred bed gas-phase reactor, add triethyla...

Embodiment 2

[0123] This example serves to illustrate compositions for polymer films and polymer films and multilayer films according to the invention.

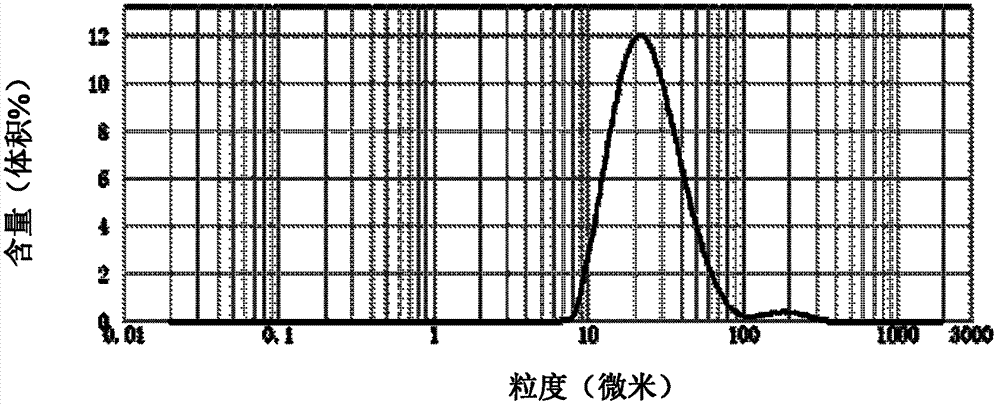

[0124] The same method as in Example 1 was used to prepare propylene polymer and polymer film, except that in step (1), the amount of solid components with a particle size in the range of 14-30 μm was 90% by volume.

[0125] During the polymerization process, there was no phenomenon that the polymer particles blocked the material discharge pipe of the reactor. The composition and properties of the propylene polymers prepared are shown in Table 1. The onset heat-sealing temperature and thermal blocking resistance of the prepared polymer films are shown in Table 1.

Embodiment 3

[0127] This example serves to illustrate compositions for polymer films and polymer films and multilayer films according to the invention.

[0128] The same method as in Example 1 was used to prepare a propylene polymer, except that in step (1), the amount of solid components with a particle size in the range of 14-30 microns was 100% by volume.

[0129] During the polymerization process, there was no phenomenon that the polymer particles blocked the material discharge pipe of the reactor. The composition and properties of the propylene polymers prepared are shown in Table 1. The onset heat-sealing temperature and thermal blocking resistance of the prepared polymer films are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com