A kind of high heat-sealing strength puncture-resistant BOPP film and preparation method thereof

A puncture-resistant and high-strength technology, applied in the field of high heat-sealing strength puncture-resistant BOPP film and its preparation, can solve the problems of bag breakage, poor impact resistance of packaging bags, environmental pollution, etc., and achieve a low initial heat sealing temperature, The effect of good heat sealing performance and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

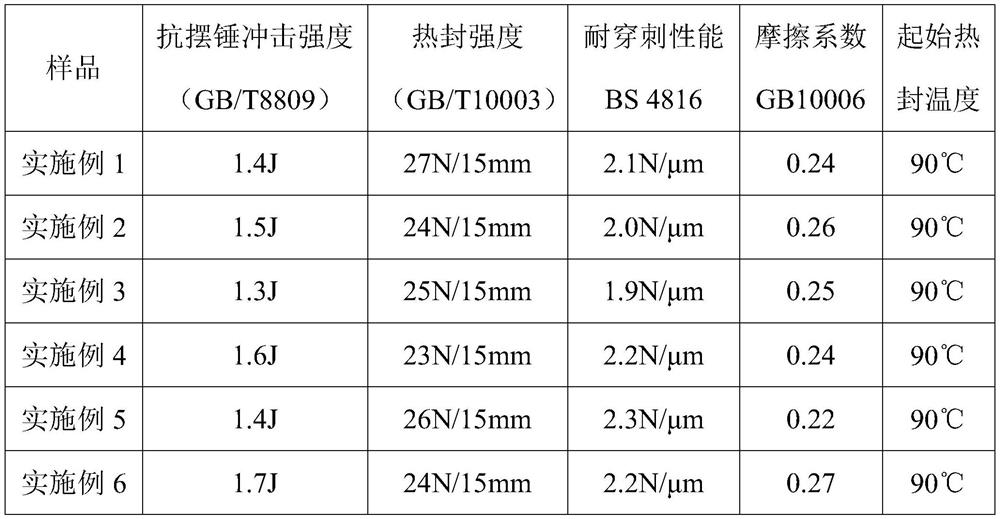

Examples

Embodiment 1

[0024] A puncture-resistant BOPP film with high heat-sealing strength, which is sequentially composed of a corona layer, a core layer, and a heat-sealing layer; the raw materials of the corona layer are composed of 95 parts of homopolypropylene and 5 parts of anti-adhesive masterbatch A in parts by weight ; The raw material of the anti-adhesive masterbatch A is composed of 30 parts of random silica and 70 parts of homopolypropylene by weight;

[0025] The raw materials of the core layer are composed of 80 parts of homopolypropylene, 5 parts of erucamide slip agent and 15 parts of SBS styrene thermoplastic elastomer in parts by weight;

[0026] The raw materials of the heat-sealing layer are composed of 70 parts by weight of metallocene terpolymer polypropylene, 25 parts of linear low density polyethylene and 5 parts of anti-adhesive masterbatch B; the raw materials of described anti-adhesive masterbatch B are composed of It consists of 40 parts of glass microspheres and 60 par...

Embodiment 2

[0035] A high heat-sealing strength and puncture-resistant BOPP film, which is sequentially composed of a corona layer, a core layer, and a heat-sealing layer; the raw materials of the corona layer are composed of 96 parts of homopolypropylene and 4 parts of anti-adhesive masterbatch A in parts by weight ; The raw material of the anti-adhesive masterbatch A is composed of 40 parts of random silica and 60 parts of homopolypropylene by weight;

[0036] The raw materials of the core layer are composed of 81 parts of homopolypropylene, 4 parts of erucamide slip agent and 15 parts of SBS styrene thermoplastic elastomer by weight;

[0037] The raw materials of the heat-sealing layer are composed of 72 parts by weight of metallocene terpolymer polypropylene, 24 parts of linear low density polyethylene and 4 parts of anti-adhesive masterbatch B; the raw materials of described anti-adhesive masterbatch B are composed of It consists of 50 parts of glass microspheres and 50 parts of bina...

Embodiment 3

[0046] A puncture-resistant BOPP film with high heat-sealing strength, which is sequentially composed of a corona layer, a core layer, and a heat-sealing layer; the raw materials of the corona layer are composed of 97 parts of homopolypropylene and 3 parts of anti-adhesive masterbatch A in parts by weight ; The raw material of the anti-adhesive masterbatch A is composed of 50 parts of random silica and 50 parts of homopolypropylene by weight;

[0047] The raw material of described core layer is made up of 82 parts of homopolypropylene, 4 parts of erucamide slip agents and 14 parts of SBS styrene thermoplastic elastomers by weight;

[0048] The raw materials of the heat-sealing layer are composed of 74 parts by weight of metallocene terpolymer polypropylene, 23 parts of linear low density polyethylene and 3 parts of anti-adhesive masterbatch B; the raw materials of described anti-adhesive masterbatch B are composed of It consists of 60 parts of glass microspheres and 40 parts o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com