Solid foamed drainage agent for natural gas well and preparation method of solid foamed drainage agent

A foam drainage agent and natural gas technology, applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve the problems of poor spontaneous foaming performance, weak methanol capacity, and non-environmental components, and achieve self-foaming Strong ability, convenient dosing, good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

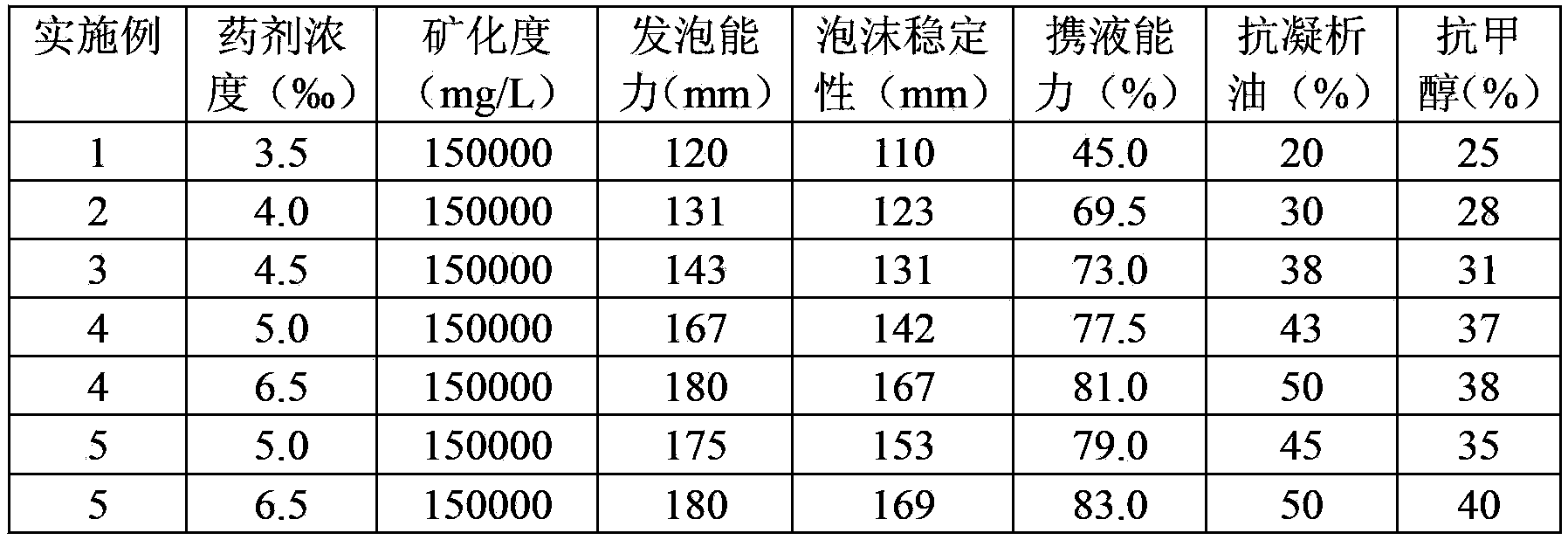

Examples

Embodiment 1

[0022] The solid foam drainage agent of the present invention is made of the following raw materials in mass ratio: 30% of surfactant, 2% of imidazoline quaternary ammonium salt, 10% of sodium peroxide, 20% of citric acid and 38% of thiourea.

[0023] The mass percentage of each raw material in the surfactant in the solid foam drainage agent: AESA (fatty alcohol polyoxyethylene ether ammonium sulfate) 10%, lauryl dimethyl amine oxide 5%, cardamom dimethyl amine oxide 5%, AEO- 3 (fatty alcohol polyoxyethylene ether) 10%.

[0024] The concrete preparation method of solid foam drainage agent of the present invention comprises the following steps:

[0025] A. Compounding of surfactants

[0026] According to the above ratio, add the aqueous solution of lauryl dimethyl amine oxide and cardamom dimethyl amine oxide into a 500ml three-neck flask equipped with a stirrer, reflux tube, and thermometer. When the temperature rises to 80°C, add AESA and AEO-3 , stirred and heated up to 12...

Embodiment 2

[0030] The solid foam drainage agent of the present invention is made of the following raw materials in mass ratio: 28% of surfactant, 3% of imidazoline quaternary ammonium salt, 12% of sodium peroxide, 25% of citric acid and 32% of thiourea.

[0031] The mass percentage of each raw material in the surfactant in the solid foam drainage agent: AESA 10%, lauryl dimethyl amine oxide 5%, cardamom dimethyl amine oxide 5%, AEO-38%.

[0032] The concrete preparation method of solid foam drainage agent of the present invention comprises the following steps:

[0033] A. Compounding of surfactants

[0034] According to the above ratio, add the aqueous solution of lauryl dimethyl amine oxide and cardamom dimethyl amine oxide into a 500ml three-necked flask equipped with a stirrer, reflux tube, and thermometer. When the temperature rises to 100°C, add AESA and AEO-3 , stirred and heated to 120°C, refluxed at constant temperature for 1 hour, and then distilled off the water, and the compo...

Embodiment 3

[0038] The solid foam drainage agent of the present invention is made of the following raw materials in mass ratio: 28% of surfactant, 1% of imidazoline quaternary ammonium salt, 10% of sodium peroxide, 21% of citric acid and 40% of thiourea.

[0039] The mass percentage of each raw material in the surfactant in the solid foam drainage agent: AESA 15%, lauryl dimethyl amine oxide 2.5%, cardamom dimethyl amine oxide 2.5%, AEO-38%.

[0040] The concrete preparation method of solid foam drainage agent of the present invention comprises the following steps:

[0041] A. Compounding of surfactants

[0042] According to the above ratio, add the aqueous solution of lauryl dimethyl amine oxide and cardamom dimethyl amine oxide into a 500ml three-necked flask equipped with a stirrer, reflux tube, and thermometer. When the temperature rises to 90°C, add AESA and AEO-3 , stirred and heated to 120°C, refluxed at constant temperature for 1 hour, and then distilled off the water until the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| foam stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com