Blasting compaction method for treating closure section

A technology of blasting, squeezing, and processing methods, applied in water conservancy projects, marine engineering, embankments, etc., can solve the problems of wasting stone construction progress, complicated and slow construction of closing sections, etc., to facilitate turning around, saving construction time, and saving stone materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: a treatment method for blasting and silting closing section, comprising the following steps:

[0018] ① Select the position of the closing section: the closing section is a straight line section, the silt is relatively shallow, and the closing section is in the range controlled by the same cross-sectional diagram as a whole, so that the explosive charge of each hole during blasting can be ensured to be relatively small;

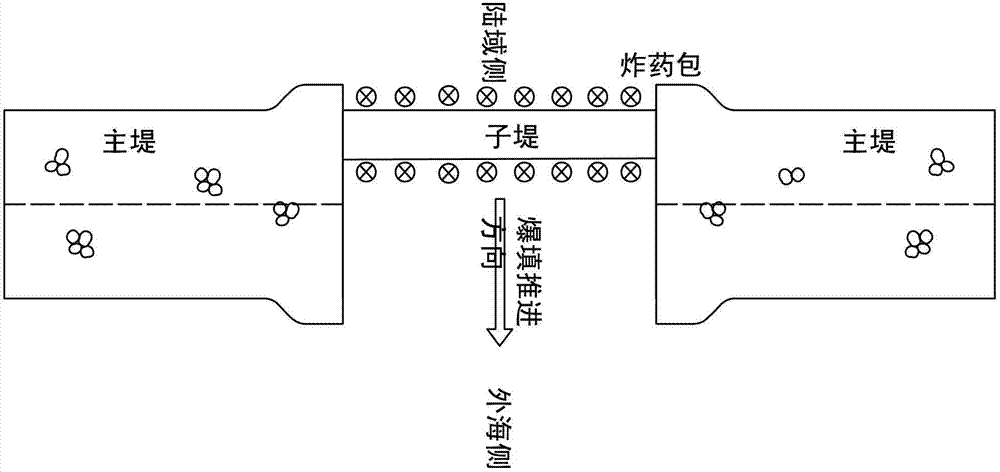

[0019] ②Using the technology of blasting and squeezing silt to build a sub-dyke at the position of the closing section, the body of the sub-dyke gradually widens from the closing section close to the land side to the side close to the outer sea, and the advancing direction of the sub-dyke is perpendicular to the axis of the main dyke. Until the sub-dike smoothly transitions to a part of the main dike, the closure of the main dike is completed; the process of building the sub-dike is as follows:

[0020] ②-1 Throwing filling: the height of...

Embodiment 2

[0024] Embodiment 2: a treatment method for blasting and squeezing silt closing section, comprising the following steps:

[0025] ① Select the position of the closing section: the closing section is a straight line section, the silt is relatively shallow, and the closing section is in the range controlled by the same cross-sectional diagram as a whole, so that the explosive charge of each hole during blasting can be ensured to be relatively small;

[0026] ②Using the technology of blasting and squeezing silt to build a sub-dyke at the position of the closing section, the body of the sub-dyke gradually widens from the closing section close to the land side to the side close to the outer sea, and the advancing direction of the sub-dyke is perpendicular to the axis of the main dyke. Until the sub-dike smoothly transitions to a part of the main dike, the closure of the main dike is completed; the process of building the sub-dike is as follows:

[0027] ②-1 Throwing filling: the he...

Embodiment 3

[0031] Embodiment 3: A kind of treatment method of blasting and squeezing silt closing section, comprises the following steps:

[0032] ① Select the position of the closing section: the closing section is a straight line section, the silt is relatively shallow, and the closing section is in the range controlled by the same cross-sectional diagram as a whole, so that the explosive charge of each hole during blasting can be ensured to be relatively small;

[0033] ②Using the technology of blasting and squeezing silt to build a sub-dyke at the position of the closing section, the body of the sub-dyke gradually widens from the closing section close to the land side to the side close to the outer sea, and the advancing direction of the sub-dyke is perpendicular to the axis of the main dyke. Until the sub-dike smoothly transitions to a part of the main dike, the closure of the main dike is completed; the process of building the sub-dike is as follows:

[0034] ②-1 Throwing and filli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com