Method for preventing explosion damage by using steel-concrete combined structure

A combined structure and concrete technology, applied in building construction, architecture, etc., can solve problems affecting the mechanical safety of the overall structure and preventing structural damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

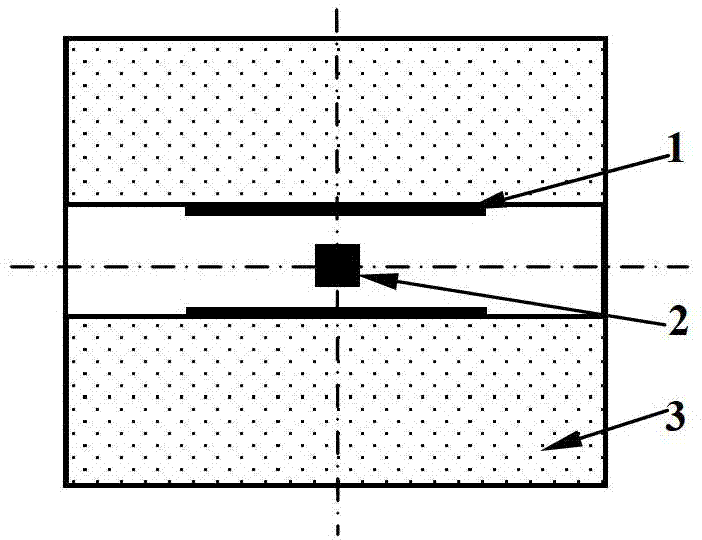

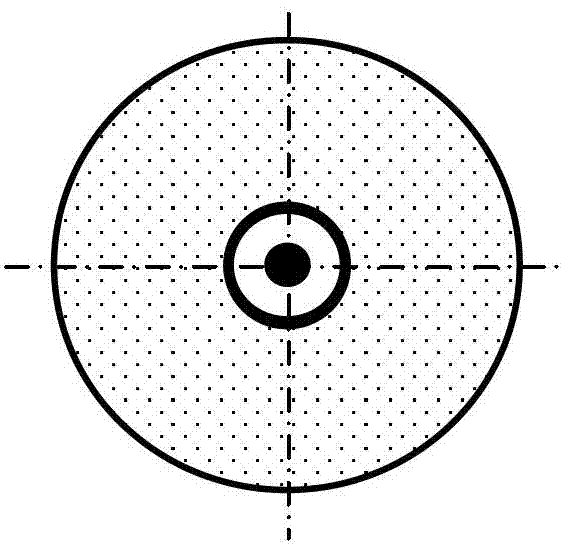

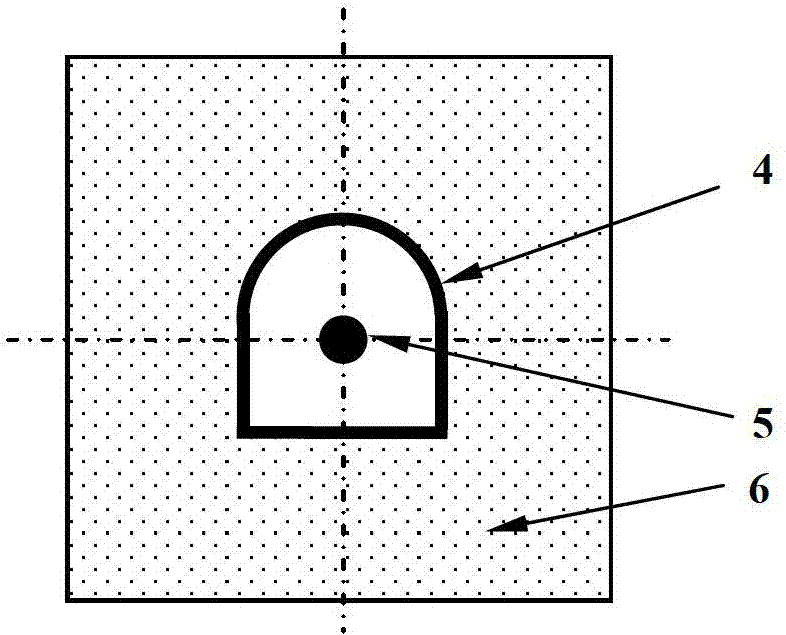

[0029] 1. Steel-concrete composite members:

[0030] 1) The experiment uses two semicircular concrete blocks with an outer diameter of 1160mm, a length of 1000mm, and an inner diameter of 180mm. A Q 345R steel pipe with a length of 600mm, an inner diameter of 141mm, and a wall thickness of 9mm is placed inside the concrete block, and there is no plugging at both ends; After the explosion experiment with 425g TNT explosive in the center, it was detected that the surface concrete at the parting surface of the explosion center of the concrete block was crushed, and the concrete at the explosion center had obvious compaction marks, but the concrete block as a whole was not damaged; The residual deformation of the circular tube is used as the basis for evaluating the protective effect, and the specific impulse absorbed by the steel structure I s and the specific impulse absorbed by concrete I c The research results show that for the concrete structure with the same thickness, when...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com