Floor plate steel truss structure

A steel truss and floor slab technology, applied in the field of floor slab steel truss structures, can solve problems such as unreasonable truss structures, damage to the bearing strength of floor slabs, and easy de-soldering, so as to achieve difficult de-soldering, high load-bearing capacity, and enhanced overall strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

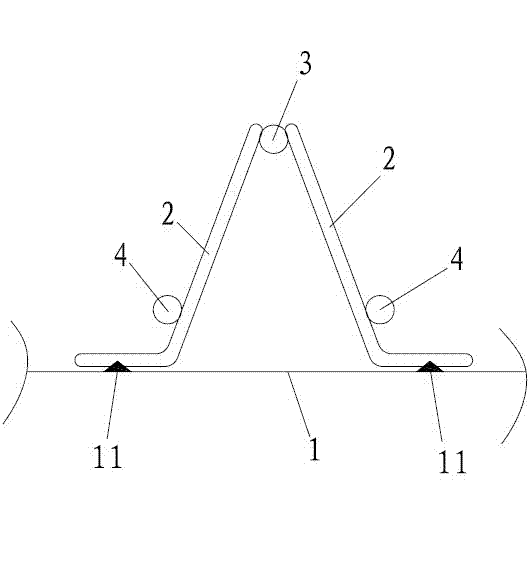

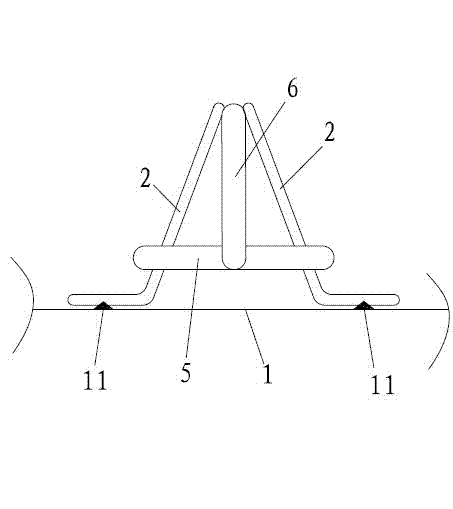

[0015] Embodiment: A kind of floor plate steel truss structure, such as Figure 1-2 As shown, bottom mold 1 is included, and bottom mold 1 has the welding bar 11 that cross section is triangular, and generally the spacing between two welding bars 11 of every pair of welding bars 11 is 10-15cm, and the present embodiment is 12cm; The bottom of reinforcement bar 2 is welded on corresponding welding bar 11, and upper chord reinforcement 3 is all welded between the upper end of every pair of web reinforcement 2, and the bottom of each web reinforcement 2 is welded with lower chord reinforcement 4; The length direction of upper chord reinforcement 3 and The length direction of the web bars 2 is in the same direction; the horizontal bars 5 are fixedly connected between the two ends of each pair of lower chord bars 4 on the same side; the horizontal bars 5 are perpendicular to the lower chord bars 4; the horizontal bars 5 are fixedly connected to the upper chord bars 3 There are vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com