Cast-in-place concrete floor punching pipe seal template device and using method

A cast-in-situ concrete floor and pipeline technology, which is applied in the fields of formwork/formwork/work frame, on-site preparation of building components, construction, etc., can solve problems such as difficulty in setting lower formwork, poor concrete pouring, and impact on project quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The specific operation steps are as follows:

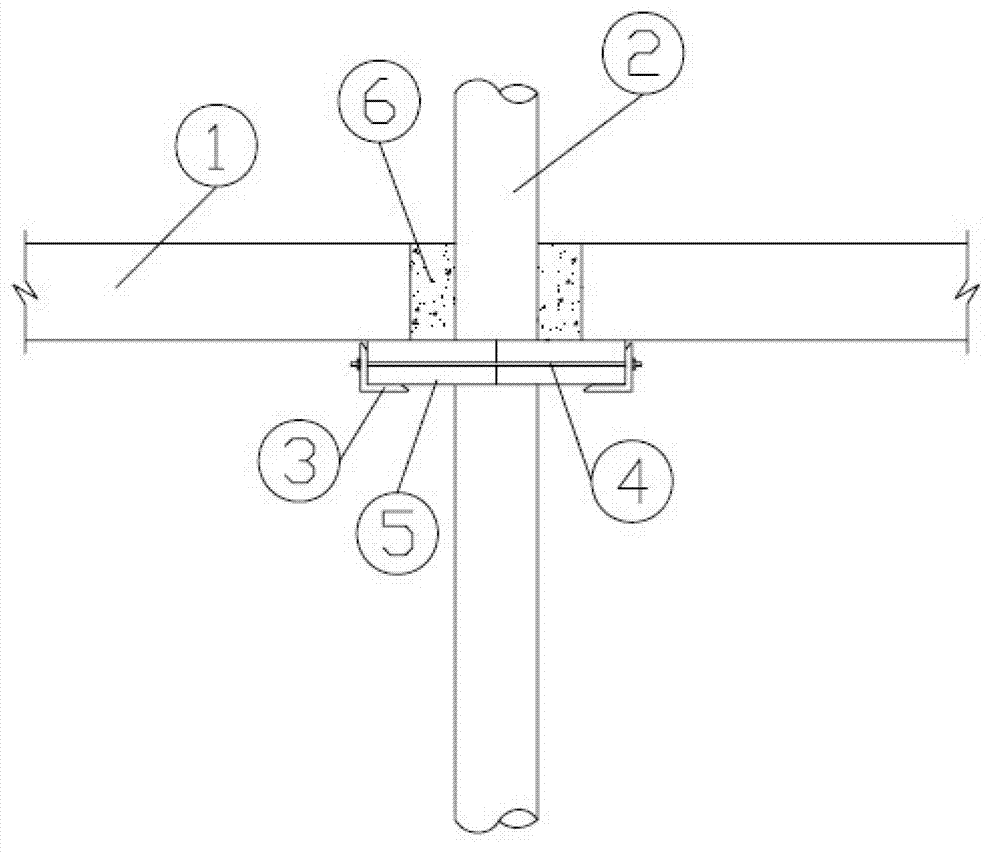

[0022] (a) Pass the pipeline 2 through the reserved cavity on the concrete floor 1 and fix it;

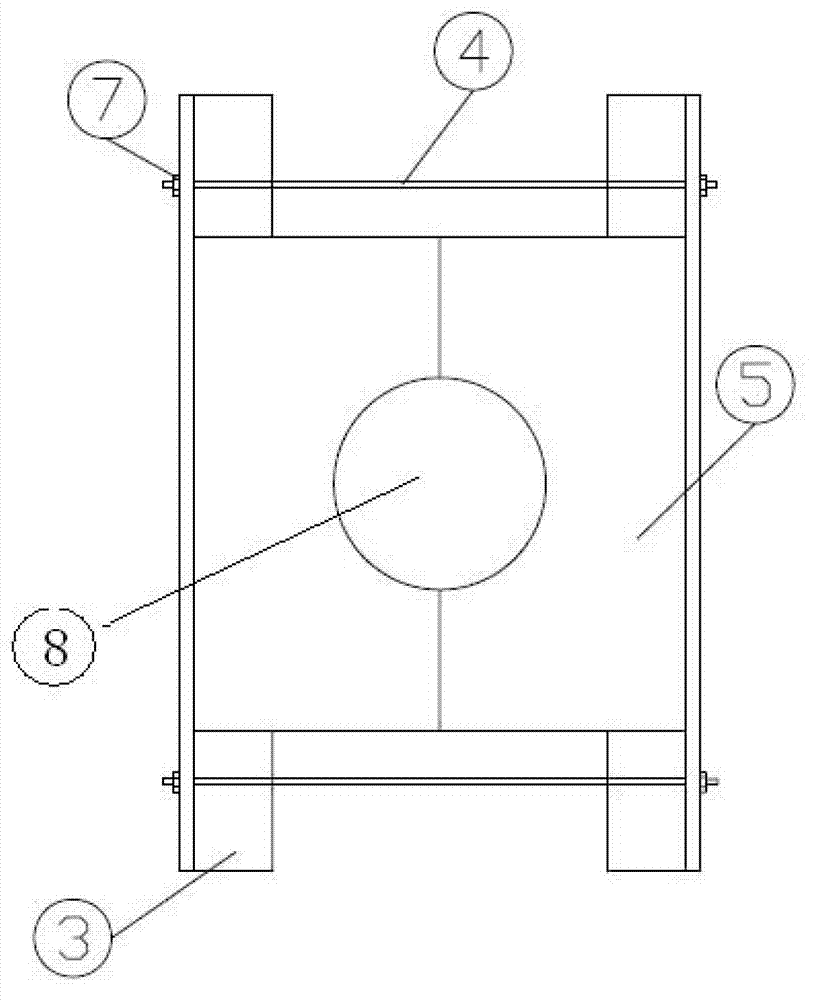

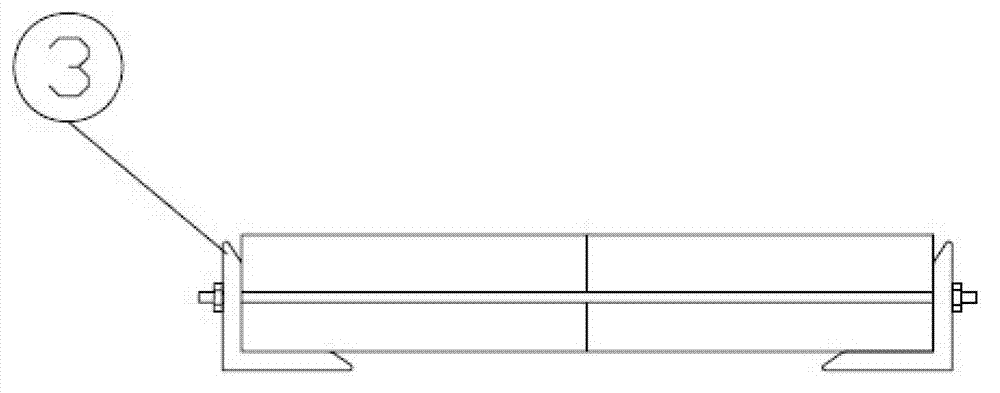

[0023] (b) Clamp the pipe 2 with two wooden formwork 5 close to the lower surface of the concrete floor 1, the through hole 8 coincides with the outer surface of the pipe 2, and then place two angle steel frames 3 on both sides of the wooden formwork 5 , turn the nut 7 to shorten the distance between the two angle steel frames 3, so that the two wooden templates 5 clamp the pipe 2, and use the friction between the wooden template 5 and the pipe 2 to make the wooden template 5 and the angle steel frame 3 will not slide;

[0024] (c) After the wooden formwork 5 is fixed, the fine stone concrete 6 is poured between the concrete floor 1 and the pipe 2. After the fine stone concrete 6 is solidified, the wooden formwork 5 and the angle steel frame 3 can be removed by loosening the nut 7 and Turnaround use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com