Composite leakage-proof reinforcing sheet and preparation method thereof

A reinforcing sheet and composite technology, applied in the field of medical materials, can solve the problems of seldom used in the field of medical and surgical implantation, and achieve the effects of accelerating tissue healing, shortening the process flow, and improving responsiveness and compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

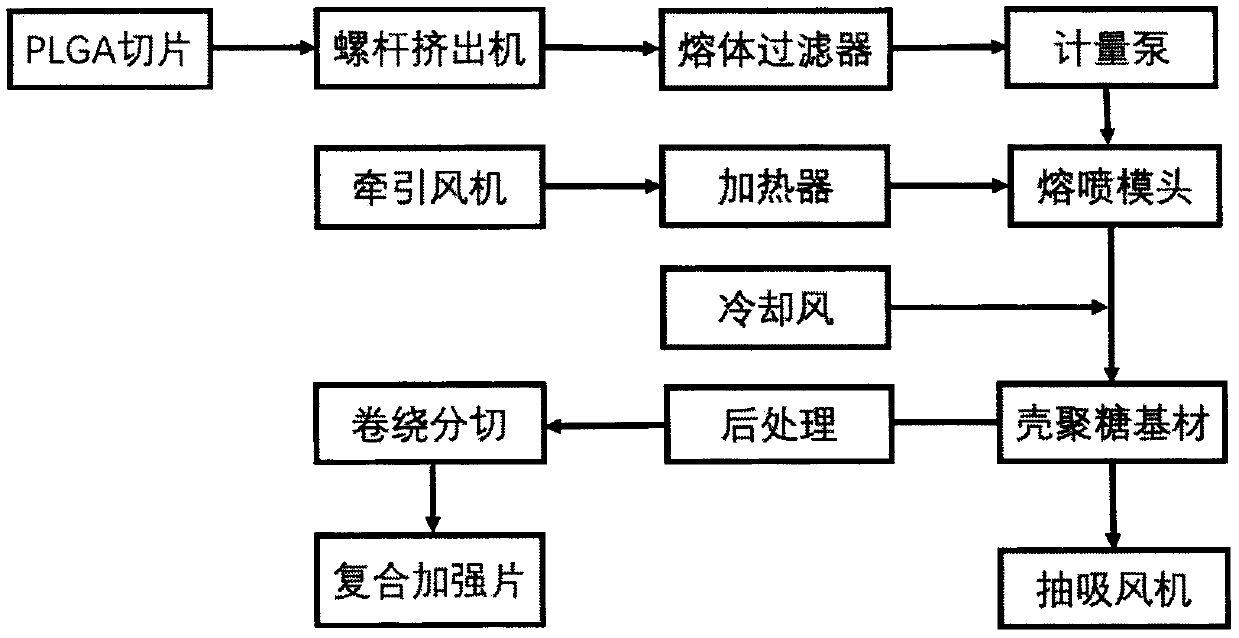

[0027] The preparation process flow chart of composite leak-proof reinforcing sheet of the present invention is as figure 1 As shown, it specifically includes the following steps:

[0028] 1. Preparation of Chitosan Layer

[0029] A. the preparation of chitosan film: chitosan solution is made in the dissolving acetic acid solution of appropriate amount of chitosan, and acetic acid concentration is 1wt%~5wt%, is preferably 2wt%~4wt%, most preferably is 3wt%; Chitosan The concentration is 1wt%-3wt%, preferably 1.5wt%-2.5wt%, most preferably 2wt%. When the concentration of chitosan is greater than 3wt%, the chitosan is too viscous and the film-forming is uneven; when the concentration of chitosan is less than 1wt%, it is difficult to form and peel off the film and the film-forming strength is too low. Filter the chitosan solution with a No. 2 sand core funnel at a pressure of 0.8-1 MPa. After vacuum defoaming, cast it on a polytetrafluoroethylene plate to form a film, dry it in...

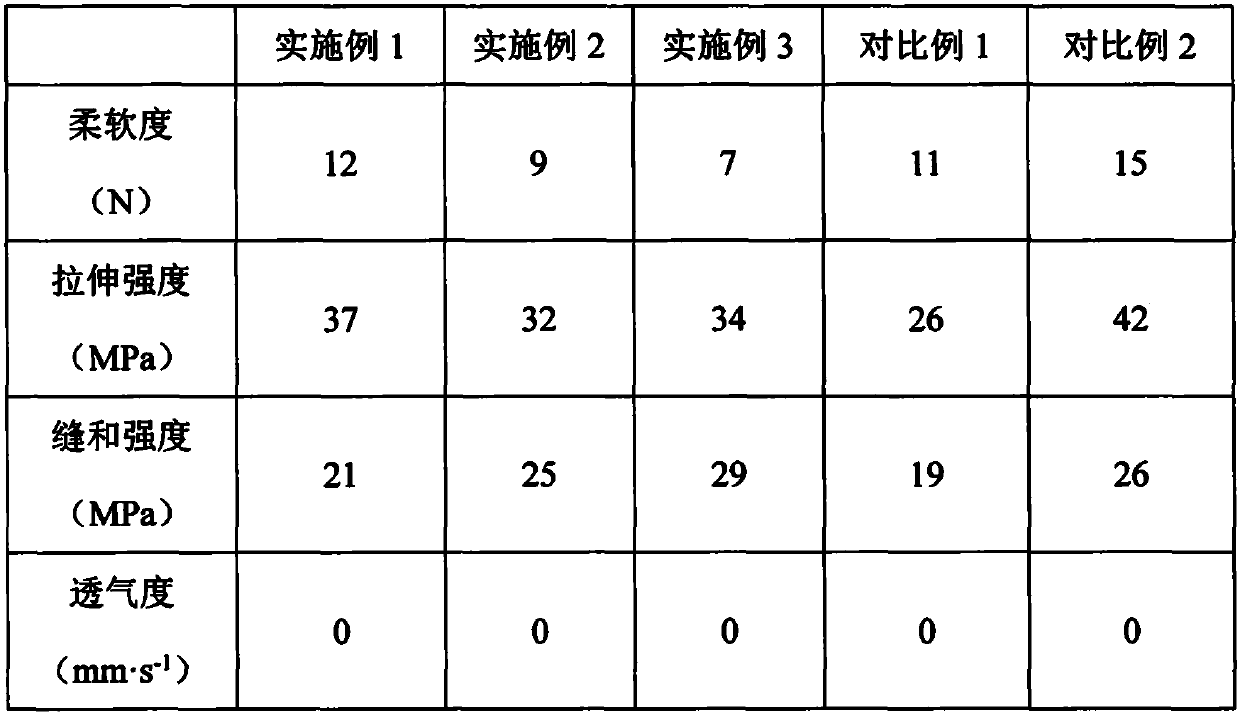

Embodiment 1

[0041] The preparation process of the composite leakage-proof reinforcing sheet of the present embodiment is as follows:

[0042] (1) Get 2g chitosan and dissolve in acetic acid solution to make chitosan aqueous solution, the concentration of acetic acid in the chitosan aqueous solution is 3wt%; The concentration of chitosan is 2wt%. The above-mentioned chitosan solution was filtered with a No. 2 sand core funnel, and the pressure was 1 MPa. After vacuum defoaming, it was cast on a polytetrafluoroethylene plate to form a film, dried in an oven at 50°C, and then peeled off. Then put it into 1mol / L NaOH solution and soak for 24h to neutralize excess acetic acid, take it out, rinse it repeatedly with deionized water until it is neutral, and then dry it naturally for later use. The quality of the chitosan film obtained is 90g / m 2 , the thickness is 0.47mm.

[0043] (2) 3g PLGA chips (PL: PG=75: 25) are thoroughly dried and sent to the screw extruder for heating and melting spinni...

Embodiment 2

[0045] The preparation process of the composite leakage-proof reinforcing sheet of the present embodiment is as follows:

[0046] (1) Get 2g chitosan and dissolve in the acetic acid solution to make chitosan aqueous solution, the concentration of acetic acid in the chitosan aqueous solution is 1wt%, and the concentration of chitosan is 1wt%. The solution is placed in a mold and freeze-dried for 12 hours, then placed in a 1mol / L NaOH solution and soaked for 24 hours to neutralize excess acetic acid, after taking it out, rinse it repeatedly with deionized water until it is neutral and then dry it naturally for later use. The resulting chitosan Sponge quality is 21g / m 2 , with a thickness of 1.0mm.

[0047] (2) 3g PLGA chips (PL: PG=75: 25) are thoroughly dried and sent to the screw extruder for heating and melting spinning. The spinning conditions are as follows: the aspect ratio of the screw extruder is 40, the screw extruder The internal temperature is 270°C, the box tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com