Sucker rod with ultra-high molecular weight polyethylene protective layer

A technology of ultra-high molecular weight and polyethylene, which is applied to drill pipes, drilling equipment, earthwork drilling and production, etc., and can solve problems such as the limitation of the service life of sucker rods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

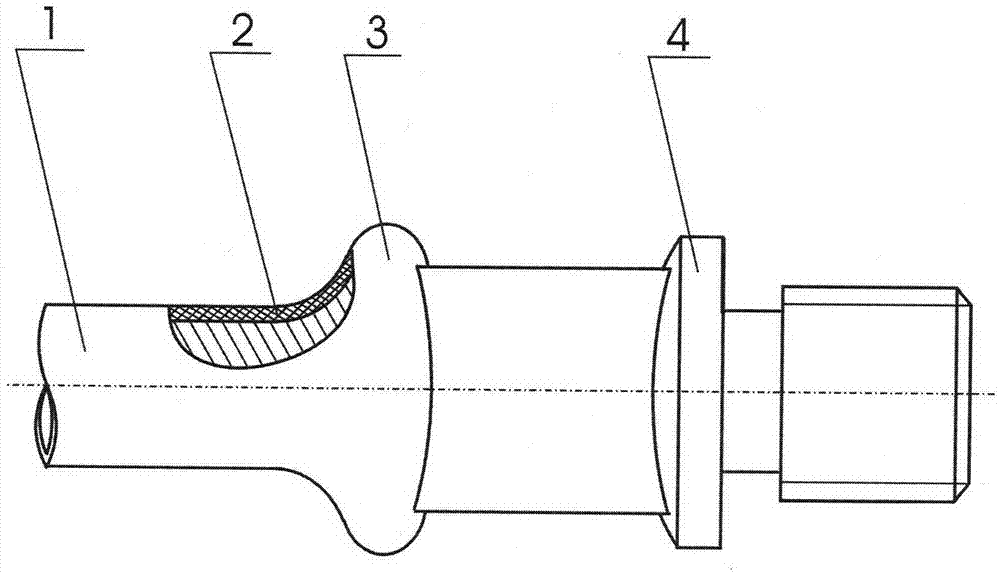

[0010] Combine below figure 1 The present invention is further described:

[0011] The inner diameter of the ultra-high molecular weight polyethylene pipe with shape memory function is larger than the outer diameter of the external thread shoulder 4 and the diameter of the flange 3 of the sucker rod before being heated, and the pipe is placed on the sucker rod 1 and heated. The pipe material returns to its original shape under thermal stimulation to form an ultra-high molecular weight polyethylene protective layer 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com