Structure and method for building side direction multicolumn gob-side entry retaining filling wall body

A technology for backfilling walls and side walls, which is applied in the fields of backfill, earthwork drilling, safety devices, etc., can solve the problems of poor effect of closed goaf, sliding instability, air leakage in goaf, etc., so as to slow down the bottom drum. , avoid impact damage, save the effect of filling materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

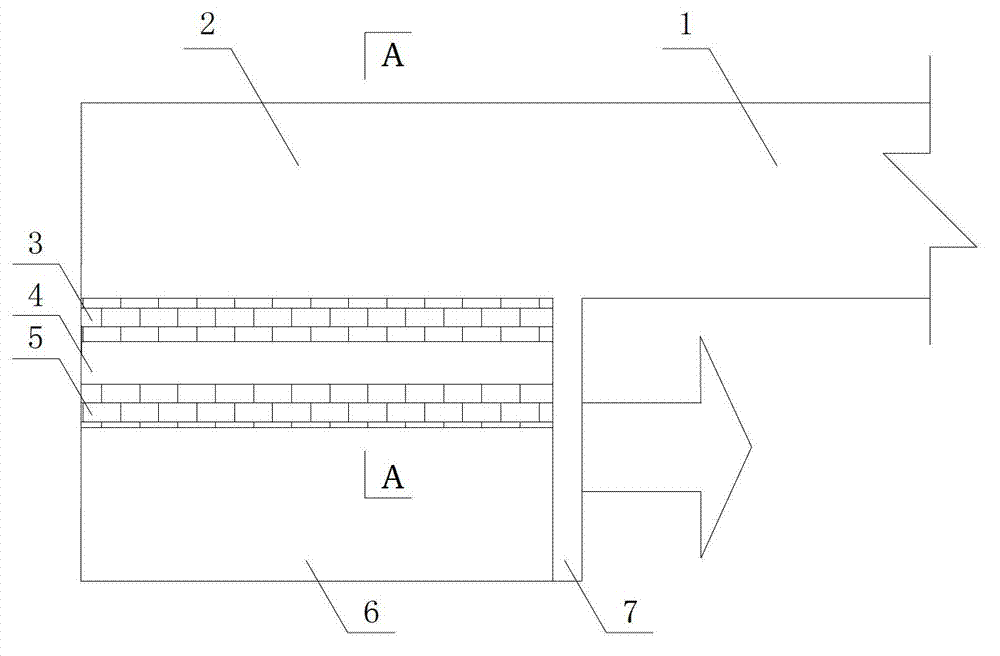

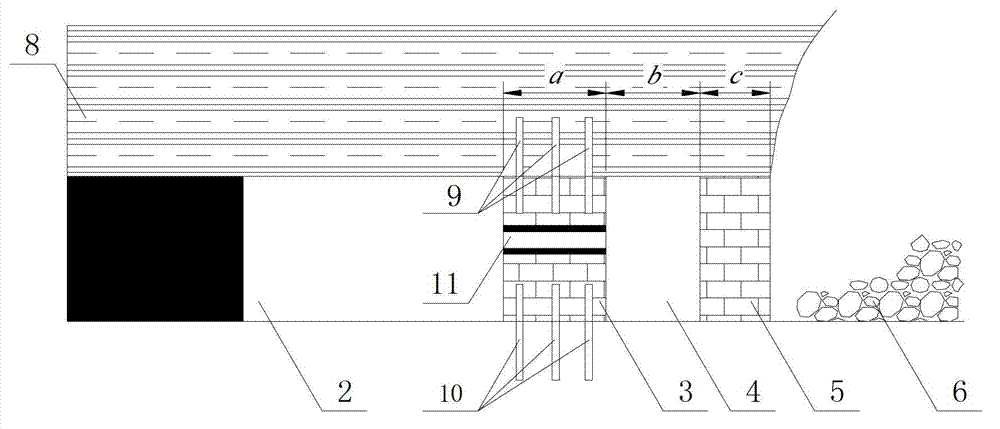

[0018] The structure of the present invention for building lateral multi-row filling walls for gob-side entry retention is mainly composed of entry retention side walls 3, middle walls 4 of high-foaming polyester materials, and goaf side walls 5. The side wall 3 and the gob side wall 5 are arranged at intervals, and the gap between the side wall 3 and the gob side wall 5 is filled with high-foaming polyester material to form the middle wall 4; The distance b between the goaf side wall 5 and the goaf side wall is 1~1.5m, the width a of the entry retaining side wall 3 is not less than 1.5~2m, and the width c of the goaf side wall 5 is not less than 1~1.5m; The passage 11 filled with high-foaming polyester material is reserved on the side wall 3 of the entry retention, the lower part of the side wall 3 of the entry retention is provided with a plurality of low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com