Differential type pilot overflow valve

A pilot overflow valve and differential technology, applied in the field of hydraulic components, can solve the problems of short life, easy damage, easy vibration and howling, etc., and achieve the effect of reducing manufacturing requirements and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

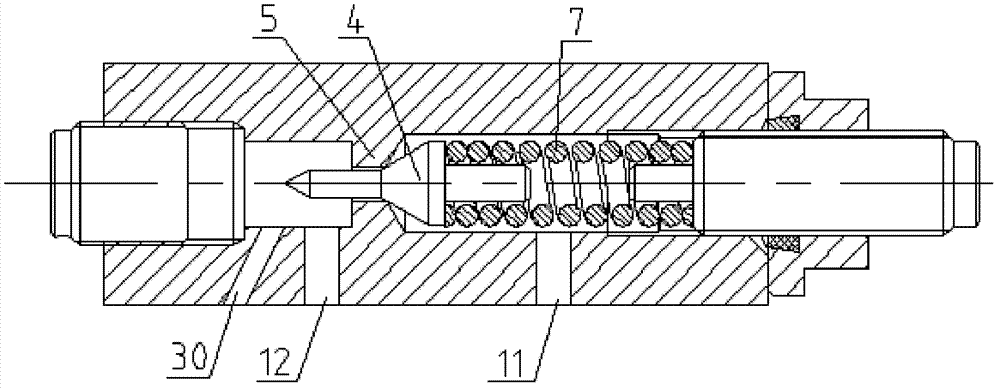

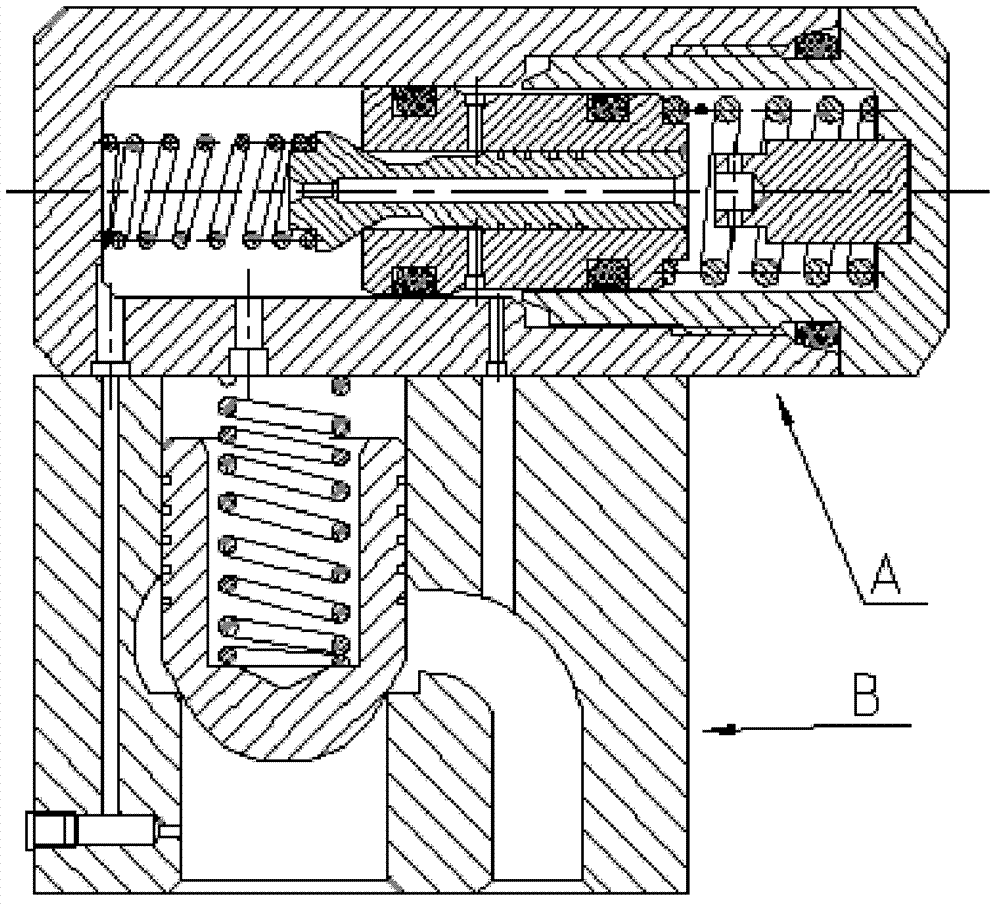

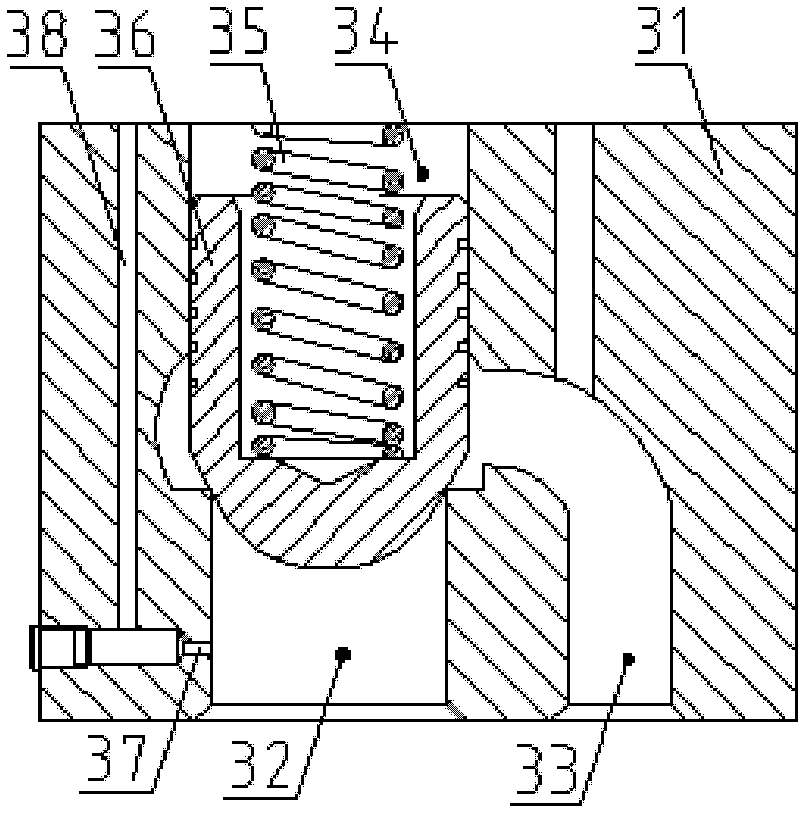

[0029] Such as figure 2 As shown, the main valve B of the differential pilot relief valve and the main valve opening device A fixedly connected with the main valve B. Such as image 3 As shown, the main valve includes a main valve body 31, and the main valve body 31 is provided with a main spool cavity and an oil spill port 33; a main spool 36 that can move axially is arranged in the main spool cavity, and the main spool One side of 36 is the main valve oil inlet 32, and the other side is the upper chamber 34, and the upper chamber 34 is provided with a return spring 35, one end of the return spring withstands the valve body 1 of the main valve opening device, and the other end withstands the main valve The core 36 pushes the main valve core 36 to the main valve oil inlet 32, and the main valve core 36 can move away from the direction of the main valve oil inlet to connect the main valve oil inlet 32 with the oil overflow port 33.

[0030] Such as Figure 4 , Figure 5 ...

Embodiment 2

[0033] Such as Figure 7 As shown, compared with Embodiment 1, the difference of the differential pilot relief valve in this embodiment is that the main valve orifice 37 is set on the main valve core 36, and the main valve orifice 37 connects the upper cavity 34 communicates with the main valve oil inlet 32, because the upper chamber 34 communicates with the first chamber 3, so the first chamber 3 is directly connected to the main valve oil inlet through the upper chamber 34 through the main valve orifice 37 connected.

Embodiment 3

[0035] Such as Figure 8 As shown, compared with Embodiment 2, the difference of the differential pilot relief valve in this embodiment is that a sealing sleeve 29 is provided on the outside of the small diameter section of the pilot valve seat 5, and the inner wall of the sealing sleeve 29 Slidingly fit with the outer wall of the small-diameter section of the pilot valve seat 5 , the two ends of the sealing sleeve 29 are in contact with the valve body 1 and the bonnet 9 respectively, and are axially positioned by being squeezed by the bonnet 9 . In this embodiment, by providing the sealing sleeve 29, the coaxiality requirement between the sealing sleeve 29 and the pilot valve seat 5 can be easily met during the manufacturing process, which can reduce the difficulty of manufacturing. Another difference is that the limiting post 8 is integrated with the bonnet 9, which can also simplify the structure and reduce manufacturing difficulty and cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com