LED chip light source module substrate

A technology of LED chip and light source module, which is applied in the direction of light source, point light source, cooling/heating device of lighting device, etc., can solve the problems of unsatisfactory treatment effect of reflective surface, affecting the light output effect of finished products, and limited light extraction efficiency of products. , to achieve the effect of good light output, strong heat dissipation, and convenient handling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The LED chip light source module substrate of the present invention will be further described in detail below in conjunction with the accompanying drawings.

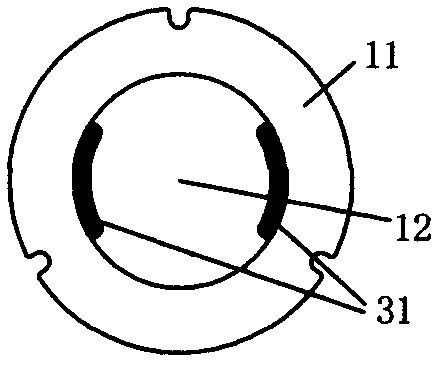

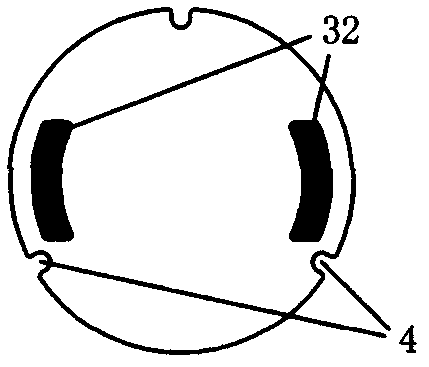

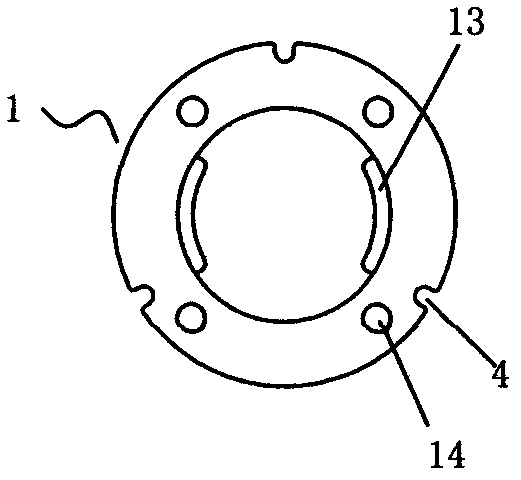

[0021] Such as Figure 1 to Figure 8 As shown, the LED chip light source module substrate of the present invention, the LED chip light source module substrate, includes two substrates, namely an upper substrate 1, a lower substrate 2 and a PCB board 3, and the PCB board 3 is embedded between the upper substrate 1 and the lower substrate 2 And it is located in the gap area between the upper substrate and the lower substrate, and the two substrates are fixed together by means of riveting and clamping. The upper substrate 1 and the lower substrate 2 are made of high thermal conductivity material, and the PCB board 3 is single-sided or double-sided, and can be designed as one or two pieces according to needs.

[0022] exist figure 1 Among them, the substrate surface 11 is coated with highly reflective materials, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com