Household appliance motor

A technology of household appliances and bearings, applied in the field of electric motors, can solve the problems of complex assembly process of brackets, low production efficiency, high production and installation costs, etc., and achieve the effects of low cost, extended service life and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

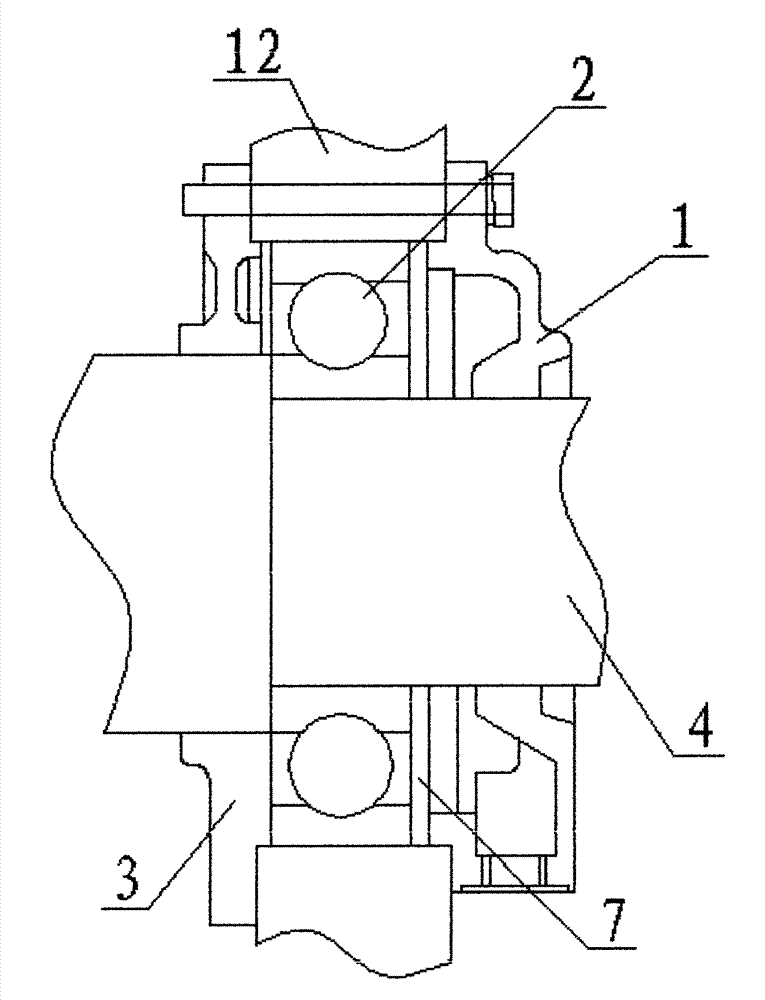

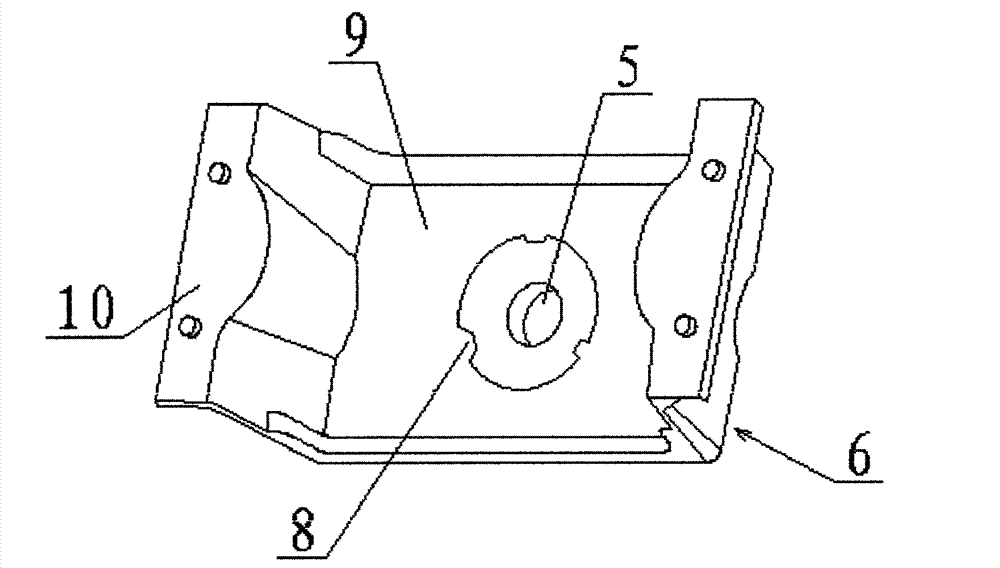

[0014] see figure 1 and figure 2 As shown, a kind of household appliance motor of the present invention comprises bearing outer cover 1, bearing 2, bearing inner cover 3, and is installed on the stator and has a support 6 of bearing chamber 5, passes the shaft 4 of stator and support 6, And the movable gap 7 is set between the end face of the outer ring of the bearing 2 and the inner spigot of the bearing outer cover 1. The bearing outer cover 1, bearing 2, and bearing inner cover 3 are installed on the shaft 4 in sequence, and the bearing 2 is located on the bearing Between the outer cover 1 and the bearing inner cover 3, several holders 8 for fixing the bearing 2 are integrally formed around the periphery of the bearing chamber 5, and the bracket 6 includes a flat base plate 9 and two ends of the base plate 9 Two arms 10 extending along the axial direction of the shaft and fixed on the stator, wherein the bearing chamber 5 is located at the center of the base plate 9 and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com