Telescopic seedling transplanter

A technology of seedlings and main rod sleeves, which is applied in the field of agricultural tools, can solve the problems of increasing the friction between the pin and the splint, increasing the labor intensity of the operator, and reducing the mechanical efficiency of the device, so as to eliminate friction, avoid uneven force, even force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

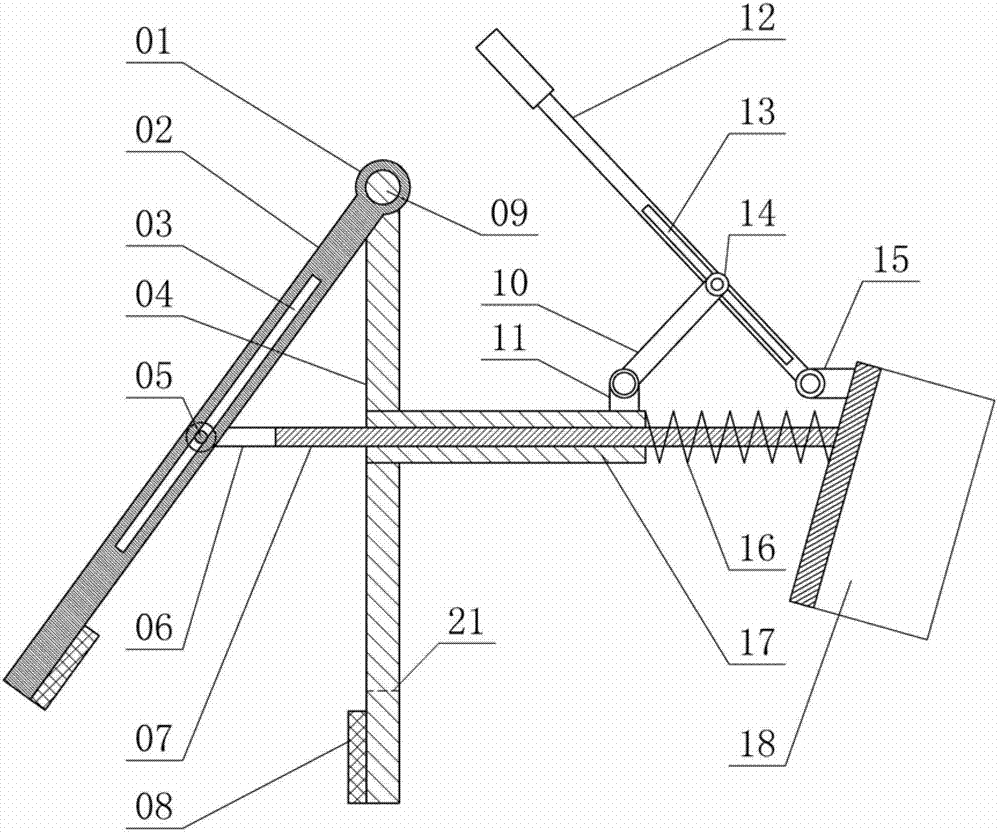

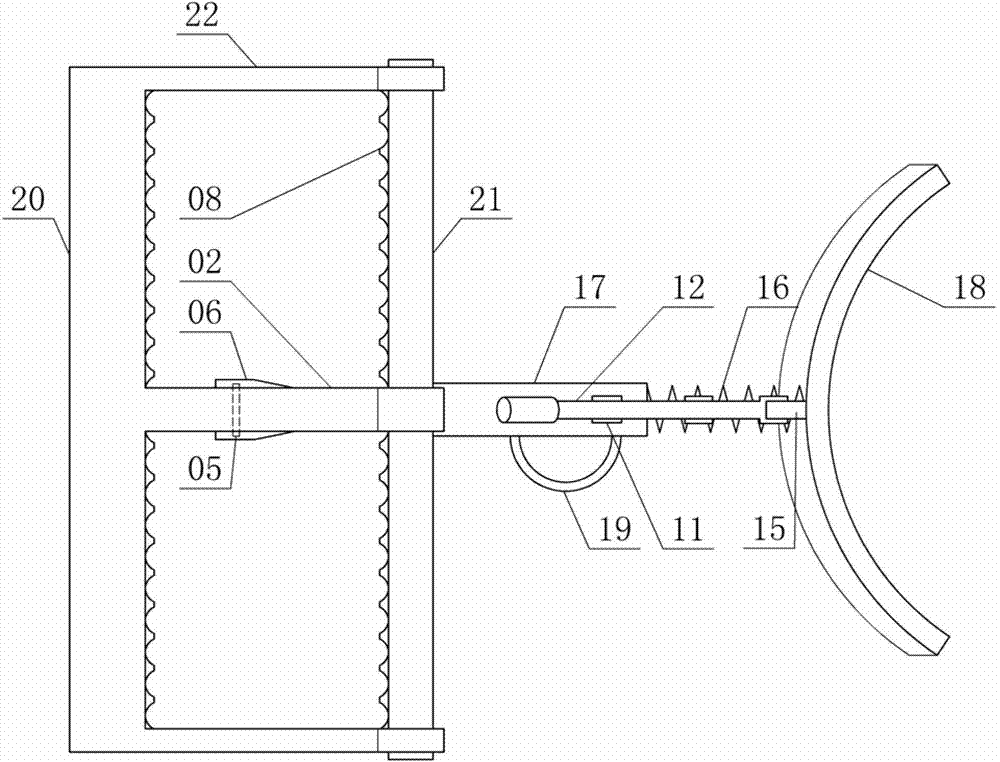

[0025] The telescopic rice seedling transplanter consists of a shaft sleeve 01, a middle forearm 02, a chute 03, a middle rear arm 04, a sliding shaft 05, a shaft fork 06, a main rod 07, a toothed pad 08, a top shaft 09, a pull rod 10, and a rotating shaft seat 11. Operating handle 12, handle chute 13, pulley 14, handle shaft seat 15, spring 16, main rod cover 17, waist support 18, handle 19, front clip 20 and rear clip 21 constitute.

[0026] Wherein, the two sections of side arms 22, the middle forearm 02 between the two sides of the arms 22, and the front clip 20 combined with the lower ends of the side arms 22 and the middle forearm 02 jointly form an E-shaped front half of the frame body; the other two sections of sides The arm 22, the middle rear arm 04 between the two side arms 22 and the rear clip 21 integrated with the lower ends of the side ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com