Corrugated pipe performance examination integrated apparatus

An integrated device and bellows technology, which is applied in the field of bellows performance inspection integrated devices, can solve the problems of low efficiency of bellows and instability of bellows, and achieve the effects of good versatility, reduced instability, and simple installation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

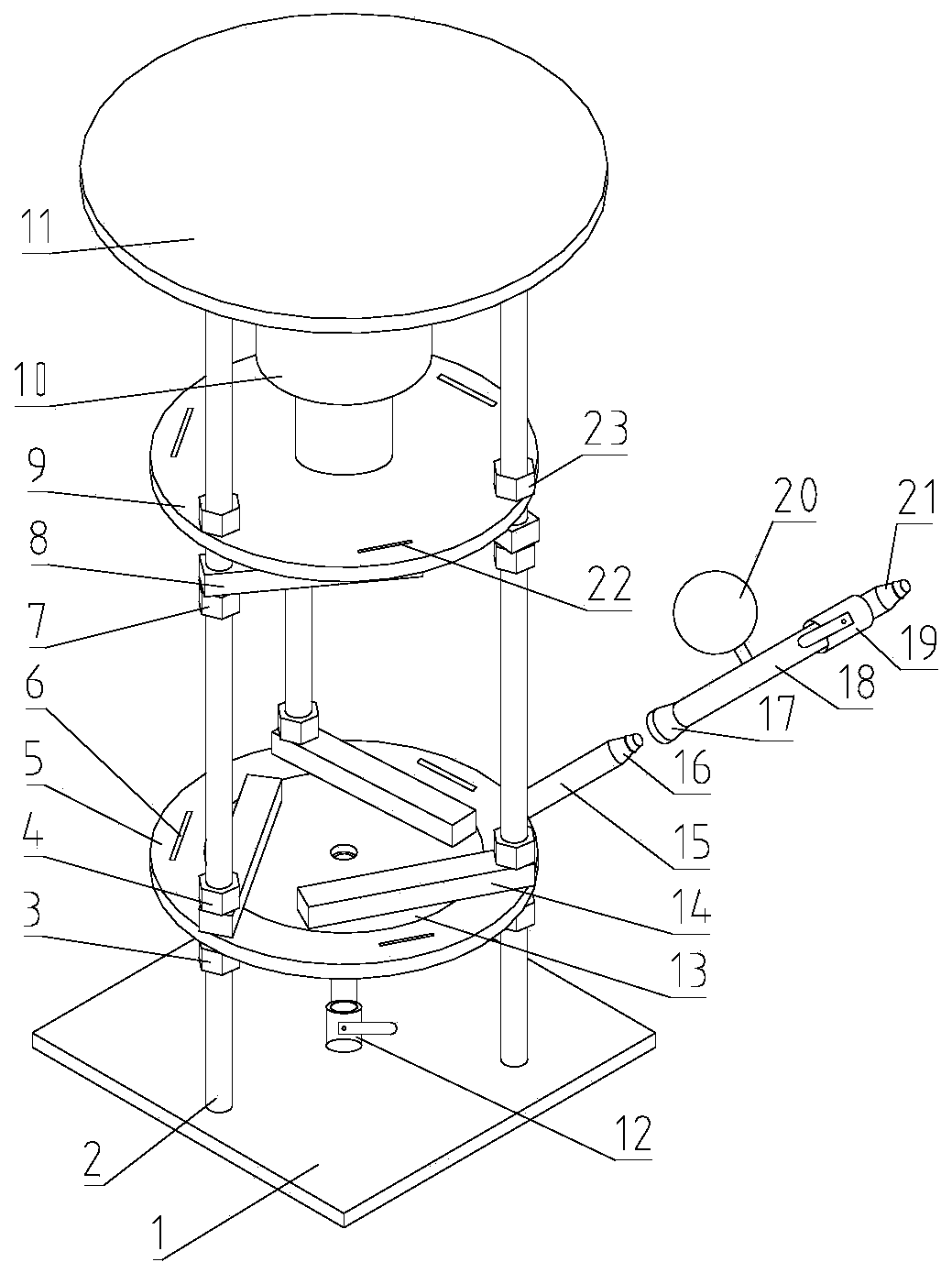

[0022] In order to make the objectives, technical solutions, and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be described clearly and completely in conjunction with the accompanying drawings in the embodiments of the present invention.

[0023] An embodiment of the present invention is an integrated device for testing the performance of a bellows, such as figure 1 Shown, including bottom plate 1, full threaded rod 2, lower support plate 5, stop baffles 8, 14, upper support plate 9, high-precision hydraulic cylinder (with pressure and displacement display) 10, upper panel 11, T-shaped tube 15 , Steel pipe 18 and shut-off valve 19, wherein the upper surface of the lower support plate 9 and the lower surface of the upper support plate 5 have been vulcanized with a layer of rubber to form a rubber gasket 13 so that it is completely attached to the flange surface of the tested bellows It is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com